Silicone Dispensing Systems: Reliable Solutions and Typical Applications for High-Precision Manufacturing

In precision manufacturing and high-end electronics, material performance directly determines product reliability and lifespan. Silicone, a high-performance synthetic polymer, is the preferred material for many critical applications due to its extremely high heat resistance, excellent elasticity, superior electrical insulation, and physiologically harmless properties. To ensure the precise, efficient, and consistent application of this high-performance material in production, a professional visual silicone dispensing machine is an indispensable core piece of equipment. This article will discuss the key role of silicone dispensing systems in light of the characteristics of silicone materials and share typical application cases.

Precisely proportioned mixing, automatic quantitative potting

1.Silicone Material Characteristics and Dispensing Process Challenges

Silicone materials are mainly divided into two categories: single-component (1K, RTV-1) and two-component (2K, RTV-2):

Single-component silicone (RTV-1): Cures by contact with moisture in the air, easy to operate, suitable for sealing, caulking, etc.

Two-component silicone (RTV-2): Cures by a chemical reaction after precise mixing of component A (base adhesive) and component B (curing agent). Its curing process is unaffected by ambient humidity, and its properties (such as hardness and modulus) have a wide adjustable range, often used in potting, encapsulation, thermally conductive bonding, and other demanding applications.

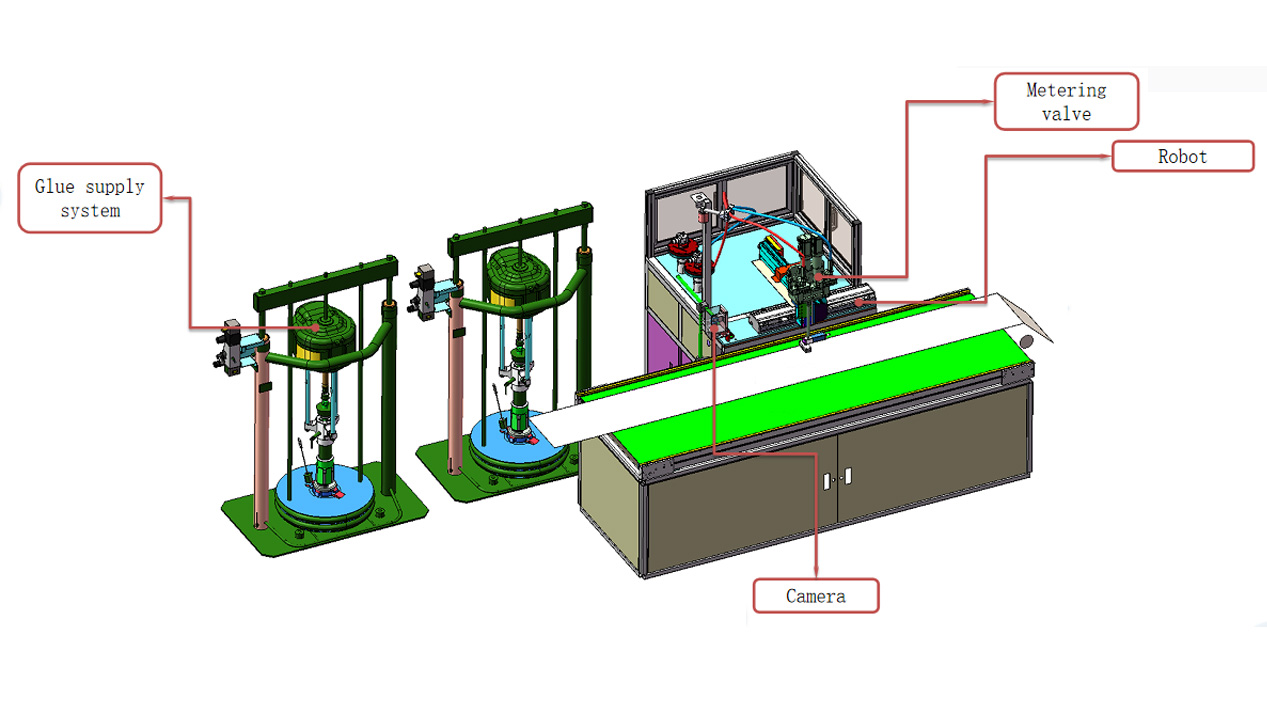

Automatic two-component glue potting machine SEC-S3030-C

- Second Intelligent’s unique motion controller plus advanced algorithms, combined with high-precision three-axis manipulators, achieve three-dimensional high-speed and precise motion

- Through precise control of the metering motor, the two-component glue can be accurately proportioned, automatically mixed, and automatically quantitatively discharged

- With vacuum feeding and vacuum degassing, optional heating, stirring, automatic cleaning, pressure monitoring and other functions, it can cope with various complex glue environments

- The operating system is stable, the operating interface is friendly, and the cost performance is high!

Ⅱ.Core Value of a Professional Silicone Dispensing System A professional silicone dispensing system perfectly addresses the above challenges through the following functions:

Precision Metering and Proportioning Control: Employing high-precision gear pumps or plunger pumps ensures stable output of 1K material or achieves precise mixing of 2K material within ±0.5%.

High-Efficiency Static Mixing Technology: For 2K silicone, the system uses dynamic or static mixing tubes to uniformly mix the two components in a very short time, eliminating dead zones and preventing subsequent layering.

Advanced Degassing and Pressure Control: An integrated vacuum degassing module pre-eliminates air bubbles in the material; closed-loop pressure control ensures consistency at the start and end of dispensing, preventing stringing and dripping.

Intelligent and Automated Integration: Integration with robots, vision systems, and production line PLCs enables precise coating of complex 3D paths, ensuring process repeatability and high production efficiency.

Two component glue dispensing potting machine SEC-S8700-E

Second Intelligent glue potting machine SEC-S8700-E is a two-component glue potting machine, which is compact and functional, flexible in manual operation, and Super cost-effective. The metering motor of this equipment is precisely controlled by PLC to achieve accurate proportioning, automatic mixing, and automatic quantitative dispensing of two-component glue. It has functions such as vacuum feeding, vacuum degassing, heating, stirring, and automatic cleaning, and can cope with various complex gluing environments; it adopts a unique industrial design, with a generous appearance, compact structure, stable operating system, friendly operating interface, and high cost-effective.

III. Typical Application Cases of Silicone Resin Dispensing

Case 1: Encapsulation Protection of Power Control Units (PCUs) in New Energy Vehicles

Requirements: Protect core power devices such as IGBTs from vibration, moisture, and chemical corrosion, and efficiently dissipate generated heat. The material must be heat-resistant (>150°C), have high thermal conductivity, be insulating, and possess a certain degree of elasticity to buffer thermal stress.

Solution: Use high thermal conductivity two-component (2K) potting silicone. The silicone dispensing system precisely measures, mixes, and vacuum degassings the silicone before injecting it into the PCU housing, completely encapsulating the electronic components. After curing, a tough and elastic protective layer is formed, achieving excellent heat dissipation, insulation, and three-proof protection, ensuring the long-term reliability of the vehicle in harsh environments.

Case 2: Waterproof Sealing of Consumer Electronics (e.g., Smartwatches)

Requirements: Form a continuous, uniform, and uninterrupted sealing ring at extremely narrow bezels and seams to achieve IP68 waterproof rating. The material must be non-toxic and harmless (physiologically harmless) and resistant to sweat and skin care product corrosion during long-term skin contact.

Solution: Use low-viscosity, one-component (1K) sealing silicone. Using a high-precision piezoelectric jet dispensing valve or screw valve, the system can dispense fine, continuous adhesive lines along millisecond-level paths with millisecond-level response speeds. The adhesive absorbs moisture from the air and cures rapidly, forming an ultra-thin and strong sealing layer, perfectly meeting the precision waterproofing and safety requirements of fashionable electronic products.

Case Study 3: Bonding and Encapsulation of Solar Photovoltaic Module Junction Boxes

Requirement: Securely bond the junction box to the photovoltaic glass backsheet and encapsulate the internal diodes and wiring, requiring it to withstand over 25 years of outdoor exposure to sunlight and rain, and high and low temperature cycling (-40°C to above 85°C).

Solution: Use a two-component (2K) bonding and encapsulation silicone with excellent weather resistance. The dispensing system first dispenses a specific pattern of adhesive lines on the bottom of the junction box for bonding, then pots the internal circuitry. Silicone resin’s excellent resistance to UV rays, ozone, high and low temperatures, and elasticity effectively mitigates the thermal expansion differences between glass, plastic, and metal, making it a key technology for ensuring long-term stable power generation in photovoltaic power plants.

Case Study 4: Comfort Sealing of Medical Devices (e.g., Respiratory Masks)

Requirement: To form a soft, skin-friendly, and airtight gasket at the contact point between a medical respiratory mask and the face. The material must be biocompatible (e.g., USP Class VI), non-toxic, odorless, easy to clean and disinfect, and maintain its softness over time.

Solution: Using medical-grade liquid silicone rubber (LSR, a type of 2K silicone). The LSR dispensing system precisely measures and mixes the material while heated, then injects it into a mold, where it is thermosetting to form a sealing gasket. This process is highly efficient, and the finished product has excellent feel, elasticity, and durability, greatly improving patient comfort and treatment compliance, fully demonstrating the physiologically harmless properties of silicone materials.

1.Conclusion The superior performance of silicone resins has earned them the reputation of “industrial vitamins” in high-end manufacturing.

However, fully realizing their potential depends heavily on precise, controllable, and efficient application. Modern silicone dispensing equipment serve as a crucial bridge connecting materials science with ultimately reliable products. From new energy vehicles to wearable devices, from clean energy to healthcare, by selecting dispensing solutions that perfectly match the material properties, manufacturers can maximize the value of silicone resins and create more durable, reliable, and advanced next-generation products.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.