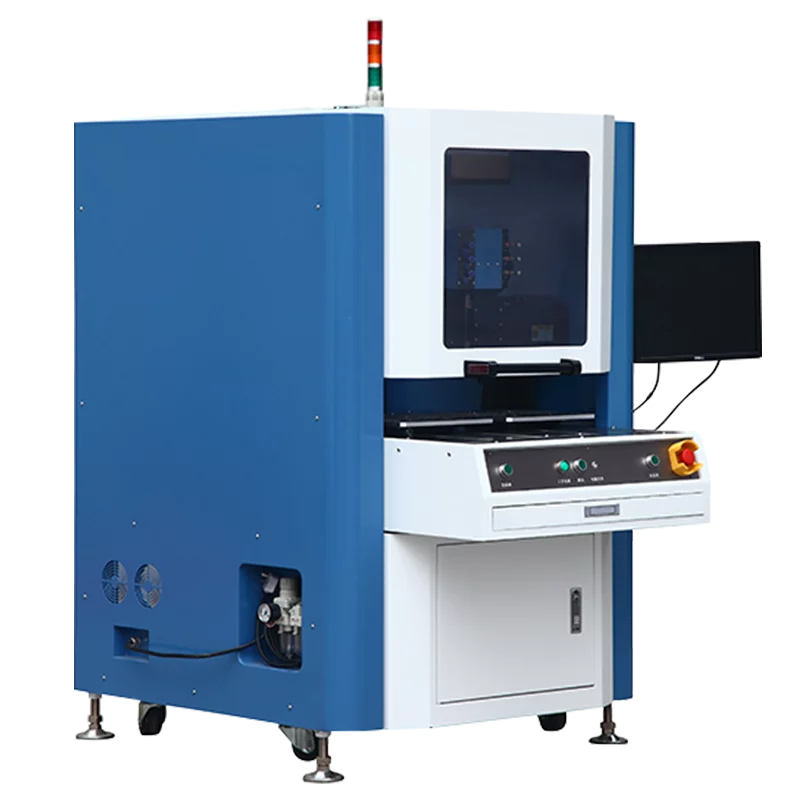

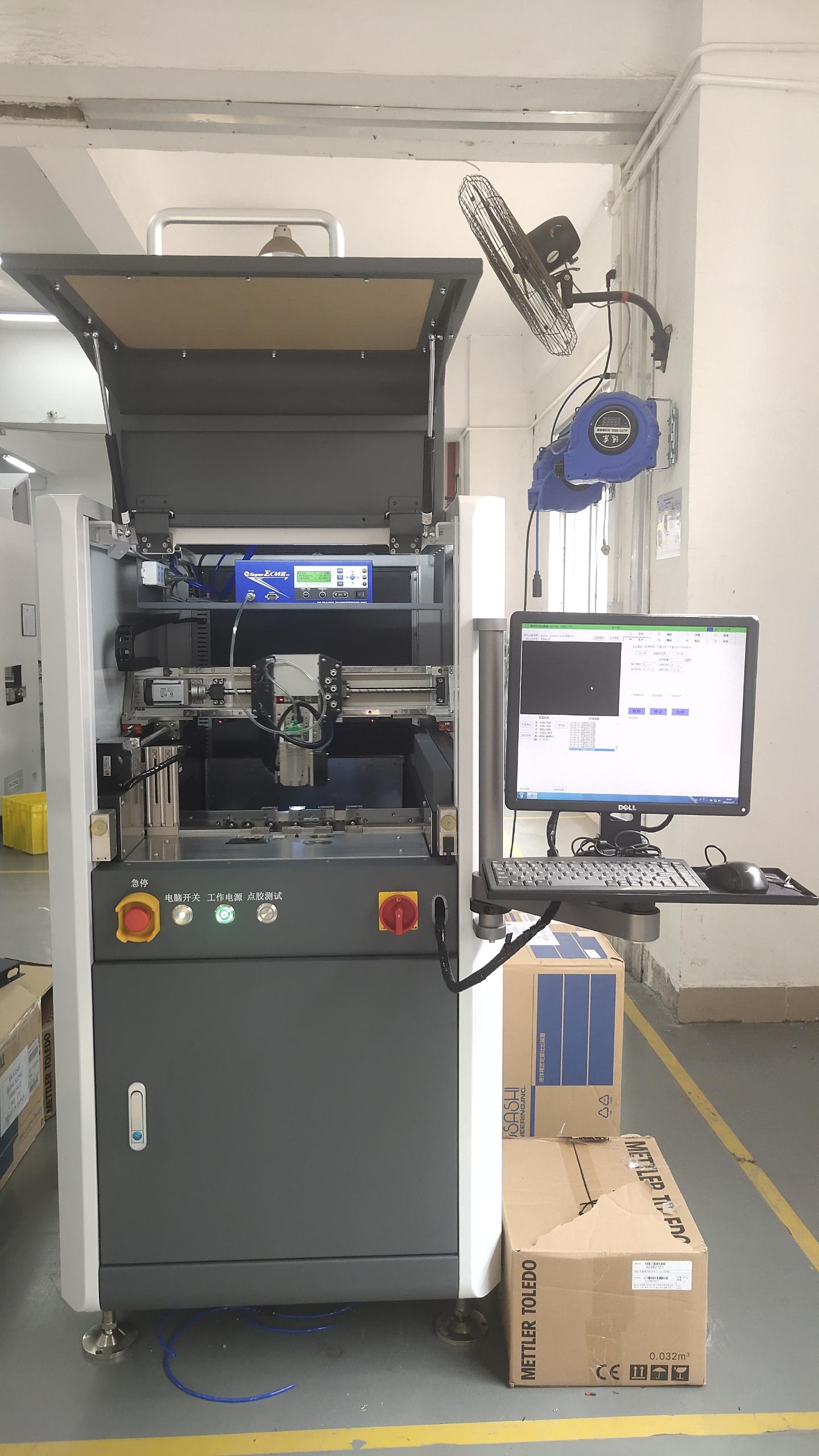

Smart high precision automated adhesive material dispensing machine with inline conveying system.

Smart high precision inline conveyor automated dispenser with CCD and laser altimetry -400DL

Description

Features

- High stability:

Granite-casting machine base, makes the equipment structure more steady and stable. The parts and components are using good brand, which assures less wearing parts and fewer faults. It is designed and built for high precision and heavy-duty works.

- Flexibility:

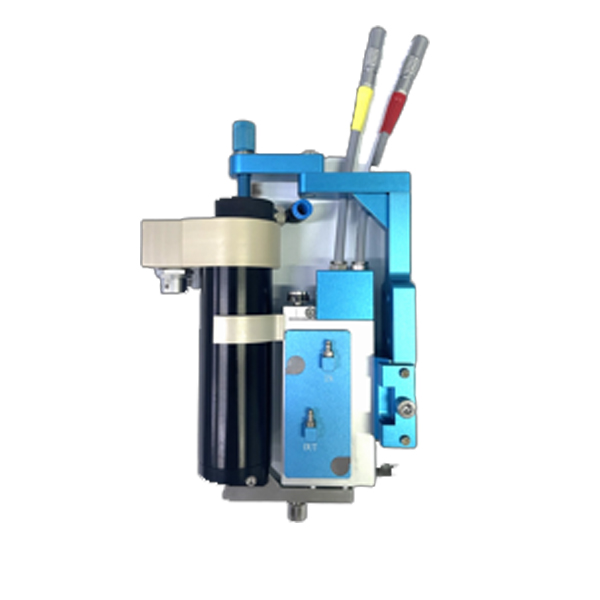

Automatic track width adjustment can adapt to different sizes of dispensing products.

It can be flexibly equipped with various functions such as needle tilting and rotation, automatic needle alignment, automatic height measurement, automatic weighing, automatic glue wiping, dual-valve synchronous/asynchronous, etc., to meet a variety of dispensing processes to achieve high-precision dispensing.

- Increase productivity:

It can be connected to an automatic assembly line operation, reducing manual intervention and improving the utilization rate.

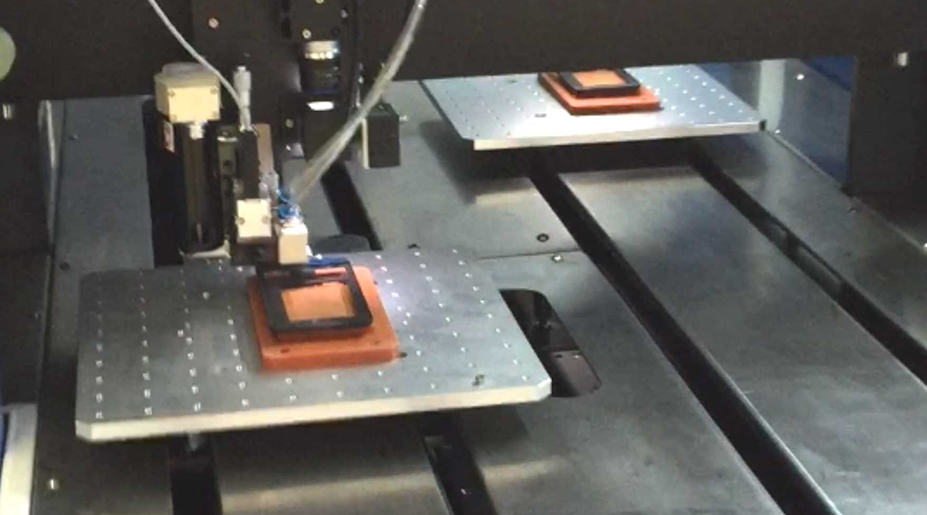

Dual-track operation can reduce the waiting time and improve production efficiency. The dual-track operation can also satisfy the dispensing of two products at the same time.

- Extensibility:

Able to add bar-code scanning system, and allow to configure to connect with the MES system to achieve big-data interaction and improve the level of workshop information management.

- Application range:

It is widely used in the EMS production line, SMT line, 3C electronics industry, LED lighting industry for high-level of automated assembly line operations.

Machine main configurations:

- Automatic Cartesian dispensing robot.

- CCD fiducial auto positioning camera.

- Laser level detection (option).

- High precision servo, and lead-screw travling system.

- Inline conveying system.

Specification

| Model | SEC-400DL | SEC-600DL | SEC-1240DL | |

| Dispensing range | X400*Y400*Z60mm | X600*Y600*Z60mm | X1200*Y400*Z100mm | |

| Travel system | Servo-motor, lead-screw | Linear-motor | ||

| XY speed | Max:1000mm/s | Max:1500mm/s | ||

| Z speed | Max:200mm/s | |||

| XYZ repeating accuracy | ±0.015mm | ±0.025mm | ±0.01mm | |

| Z-axis payload | 5Kg | 20kg | 5Kg | |

| Number of track | Single-track(Optional dual-track) | Single-track | ||

| Number of track section | 1 section(standard) | |||

| Type of conveyor track | ESD,5mm flat-belt(Optional for double-chain) | |||

| Conveying speed | Max:300mm/s | |||

| Conveyor adjust method | Program adjustable(Optional for automatic) | |||

| Conveyor payload | Max:1.7Kg | |||

| Ground-height to the track | 900±20mm | |||

| CCD visual camera | High-definetion(CCD) | |||

| Visual lighting | LED Red/Blue/White | |||

| Industrial PC | Industrial computer, LCD monitor, mouse and keyboard | |||

| Operating system | Windows 10 | |||

| Dispensing software | Second Fluent | |||

| Front-to-back machine communication protocol | SMEMA | |||

| Machine dimensions | L779*W1255*H1680mm | L1060*W1450*H1680mm | L1860*W1150*H1680mm | |

| Machine weight | 800Kg (Est.) | 650Kg (Est.) | 720Kg (Est.) | |

| Power supply | AC220V,50/60Hz,2Kw | |||

| Air-pressure | 0.65MPa±0.02MPa,0.2m³/h | |||

Machine

- Smart system equips with auto fiducial CCD visual and laser height altimetry auto positioning compensate functions.

- Equips with electric width adjusting control, easy and reliable to use.

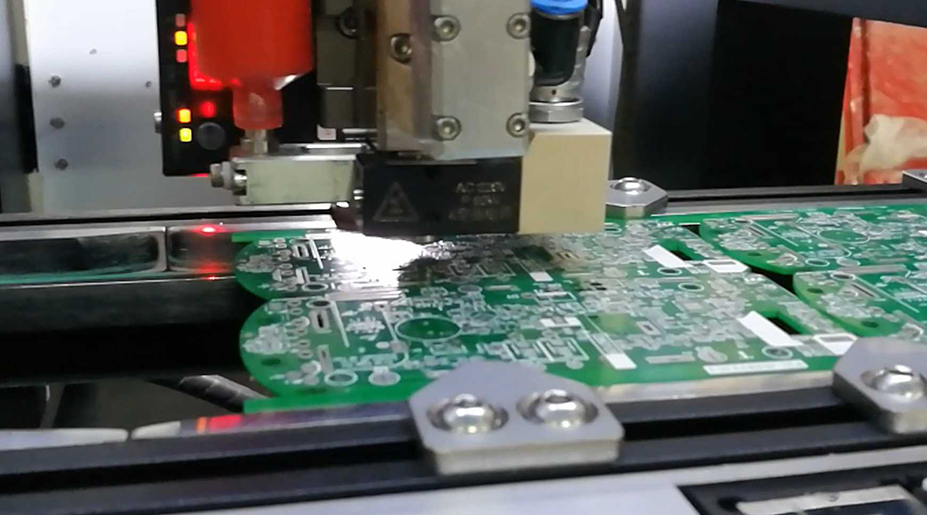

- It provides great advantages for the dispensing of PCB multi-panel productions dispensing.

It can connect to the MES system to improve the level of production information for effective management.

Material

(1)This is an inline dispensing machine working with a conveyor

(2)Adapt with different types of dispensing valves, and work with XYZ robotic control

MANUFACTURING

It produces various type of stand-lone and inline conveying dispensing systems

How It Works

It is widely used in SMT industry, telecommunication, and consumer electronics industry, LED lighting industry, and is suitable for automated assembly line operations.

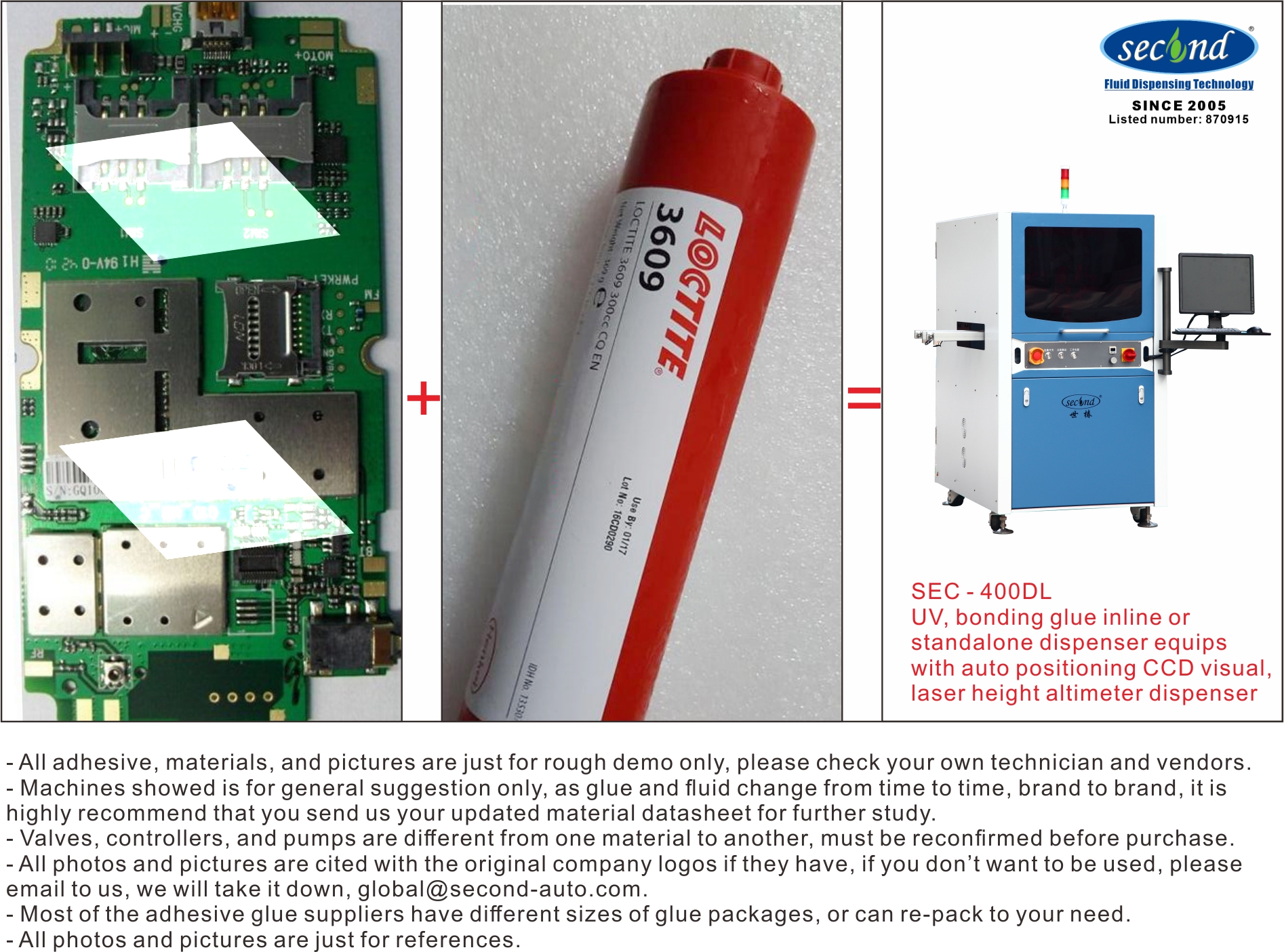

SOLUTION

.jpg)

FAQ

We are direct manufacturer.

Generally, we pack our goods with proper wooden box. However, if client has special requirment, we can customize.

Depends on terms and conditions, negotiable.

Yes, we can produce according to the tested result. We can also product base on your design.

Yes, we will test 100% before delivery.

We keep good quality and competitive price to ensure our customers benefit. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Dispensing machine is an automatic machine and equipment that specializes in controlling fluid and dripping, coating, and potting the liquid on the surface of the product or inside the product. The glue dispenser is mainly used for glue and paint in the product process.

Glue dispensers are generally suitable for small products or electronic components, which are more precise; the products of potting dispensers are generally larger.

As long as it is a fluid with a viscosity within a certain range, it can be operated. The glue generally used in the dispenser includes red glue, hot melt glue, silica gel, grease and so on.

INQUIRY FORM