Precision dispensing is a high-precision, programmable, non-contact or contact fluid-controlled coating technology developed in modern electronics manufacturing to meet the protection requirements of high reliability, miniaturization, and complex PCBAs. It marks a new stage in conformal coating, moving from “surface coverage” to “microstructure-customized protection.”

Application Case: Precision Conformal Coating of On-Board Charger (OBC) Control Board for New Energy Vehicles

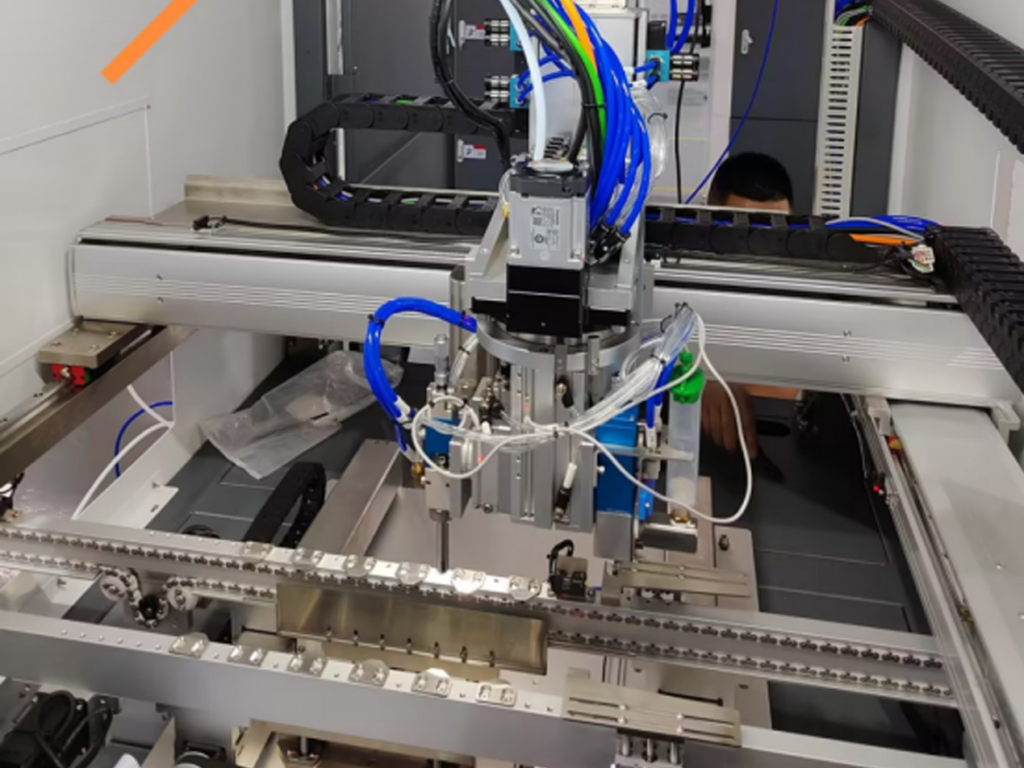

Pneumatic spray value+ Automatic Glue Dispensing Machine SEC-DH400L

1.Background and Challenges

● Product:Main control board of an on-board charger (OBC) for new energy vehicles.

● Operating Environment: Faces high humidity, condensation, drastic temperature cycling (-40°C to above 85°C), slight vibration, and potential corrosion from electrolytes and coolants.

● Traditional Process:PCBA Conformal coating (polyurethane or silicone materials) is applied using traditional selective coating machines or manual spraying.

● Core Issues:

“Shading Effect”: The components on the board have significant height differences (e.g., tall electrolytic capacitors, short surface-mount components next to heat sinks). Traditional spraying cannot evenly cover the sides and bottom of short components, creating blind spots.

Sensitive Area Contamination: Connectors, test points, and heat dissipation areas must be kept absolutely clean. Even with jigs for masking, traditional spraying carries the risk of paint overflow and atomization, leading to poor contact or reduced heat dissipation performance.

Material Waste and Inconsistency: To ensure coverage, thick overall coating is often required, leading to material waste. Furthermore, film thickness uniformity depends on operator skill, resulting in poor batch consistency.

Video: PCBA – Conformal Coating – Dust and Moisture Protection for Circuit Boards

2.Precision Dispensing Solution

To overcome these challenges, a fully automated, high-precision dispensing system was introduced, coupled with appropriate process design.

● Equipment:Employs a non-contact jet dispensing valve with a vision positioning system and a high-precision three-axis motion platform.

● Materials: Selects low-viscosity, high-penetration modified acrylic conformal coating, balancing rapid curing and excellent electrical insulation.

Second Intelligent In-line Glue Dispensing Machine SEC-DH400L adopts an integrated mineral casting design, with ultra-high precision and super stability, powerful expansion capabilities, and can realize ion cleaning, dispensing, detection, UV exposure and other functions;

Adopting a gantry structure, it can bear large loads, stable structure, and a powerful CCD visual positioning system, which can meet the requirements of Mark point positioning, edge positioning, and 3D scanning positioning; strong scalability, and can expand AOI detection 3D detection, UV exposure curing and other functions;

Strong platform compatibility, contact and non-contact dispensing, single-head and multi-head synchronous dispensing, automatic compensation and adjustment of double-head spacing, five-axis dispensing function based on needle A/R displacement, etc.

● Core Process Strategies:

1.3D Path Programming: Based on the 3D model of the PCBA, precise 3D path planning is performed for areas requiring protection (such as chips, pins, and solder joints), ensuring the glue gun can accurately reach the sides and roots of complex structures.

2.Layered and Multi-pass Dispensing: For the roots of tall components, a multi-pass process is used, first applying a layer around the base, then filling the sides along the Z-axis, ensuring a complete “dam” and protective layer is formed.

3.Non-contact Spraying: For micro-components (such as 0402 resistors and capacitors) or densely pinned areas, a spray valve is used for high-speed, micro-volume (nanoscale) dispensing, avoiding needle contact with components, and providing more controllable glue dot shape.

4.Intelligent Recognition and Avoidance: A vision system accurately locates areas requiring protection and areas requiring avoidance (such as connector gold fingers), achieving “pixel-level” precise coating.

Automatic In-line PCB Glue Dispensing Machine SEC-DH400L

3.Application Results

● Quality Improvement:

Seamless Protection: Successfully resolved the “shadow effect,” forming a continuous and uniform protective film at key weak points such as the bottom of QFN chips, between dense-pin IC pins, and at the junction of electrolytic capacitor metal casings and the PCB, significantly improving moisture and corrosion resistance.

*Zero Contamination:* Connector and heat sink surfaces are clean and free of paint, completely eliminating after-sales failures caused by conformal coating contamination.

*Conformity Guarantee:* Film thickness is controlled within the design range of 0.05-0.15mm, with a batch consistency CV value of <5%, significantly improving product quality reliability data.

● Efficiency and Cost Optimization:

*Material Savings:* Compared to overall spraying, conformal coating usage is reduced by approximately 40%-60%.

*Simplified Process:* Eliminates a large number of placement and protective tape steps, as well as subsequent cleaning and rework.

*Increased First-Pass Rate:* Coating defect rate decreased from approximately 3% with manual spraying to below 0.2%.

4.Key Process Summary

The key to the success of this case lies in the “precision” and “flexibility” of the precision dispensing process:

● Precise Dosage and Positioning:Ensures reliable coverage in micron-level areas.

● Flexible Path Adaptation:Easily handles multi-variety, small-batch production modes, quickly adapting to different board types through program switching.

● Material and Process Matching:Selecting conformal coatings with suitable viscosity, surface tension, and curing characteristics is a prerequisite for leveraging the advantages of dispensing.

5.Similar Application Scenarios

The application of precision dispensing in conformal coating is not limited to this, but is also widely applicable to:

● Consumer Electronics:Highly integrated products with waterproof requirements, such as smartwatches and TWS earphone charging cases.

● Industrial Control:Outdoor communication modules and sensor modules requiring high-strength protection in specific areas (excluding antenna contacts).

● Aerospace/Military: Fields with extremely stringent reliability requirements, necessitating “customized” encapsulation protection for every critical component.

Conclusion: In this case, precision dispensing technology elevates conformal coating from a crude “overall coverage” process to a precise “on-demand” protection strategy. By precisely controlling the position and shape of the material at the microscopic level, it fundamentally solves the inherent defects of traditional spraying. It is particularly suitable for modern PCBA products with high density, high reliability, and irregular structures, and is one of the key processes for achieving product differentiation and higher reliability standards.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.