Applications of dispensing machines in the medical industry

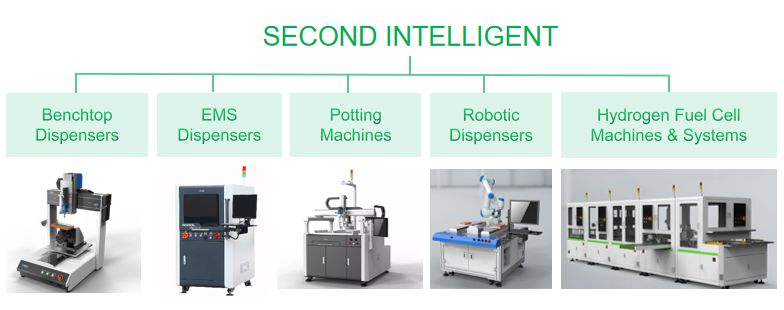

With nearly 20 years of experience in dispensing technology, Shenzhen Second Intelligent Equipment Co., Ltd. (Second Intelligent) is a well-established leader in China’s fluid application industry.

Second Intelligent dispensing machines have a wide range of applications in the dispensing of medical supplies. Compared to traditional dispensing machines, Second Intelligent dispensing machines exhibit superior performance in the pharmaceutical industry due to their advantages such as more precise dispensing, support for customer customization, and comprehensive pre-sales, in-sales, and after-sales service. The following are specific application scenarios of Second Intelligent dispensing machines in the medical supplies:

1.Automated Dispensing for Medical Needles

Dispensing Location and Function:Typically, dispensing occurs at the connection between the needle tip and the needle tube, and at the connection between the needle tube and the needle hub. Second Intelligent liquid glue dispensing machine ensure that the adhesive provides sealing and fixation, preventing issues such as leakage or needle detachment during use, thereby guaranteeing the safety and accuracy of medical procedures.

Dispensing Requirements:Extremely high biocompatibility of the adhesive is required. Second Intelligent glue dispensing machine achieve micro-volume, uniform dispensing through precise programming and control systems, meeting the high-quality production requirements of medical needles. Its precise dispensing control avoids the problems of uneven or excessive dispensing that can occur with traditional dispensing machines.

Automatic In-line PCB Glue Dispensing Machine SEC-DH400L

2.Dispensing for Medical Laryngeal Masks

Dispensing Location and Function:Dispensing occurs at the sealing edges and connection points of the laryngeal mask. Second Intelligent automatic glue dispenser machine enhances the sealing performance of the laryngeal mask, ensuring effective isolation of the respiratory tract from the external environment during use, preventing gas leakage, and ensuring a secure connection between all components, improving the overall stability and reliability of the laryngeal mask.

Dispensing Requirements:The adhesive needs to have good biocompatibility, as well as certain flexibility and corrosion resistance. Second Intelligent CNC glue dispenser can perform precise path planning and dispensing operations according to the complex shape of the laryngeal mask and the dispensing requirements of different parts, ensuring the quality and consistency of dispensing. Second Intelligent electric glue dispenser also support customized services to meet the dispensing needs of special laryngeal masks, catering to different customer requirements.

4 Axis High Precision Servo Motor Screw Automated Desktop Glue Dispensing Machine Robot SEC-E480SV

3.Dispensing for Medical Dressings

Dispensing Location and Function:Primarily dispensing occurs in the adhesive layer coating of the dressing and at the edge sealing with the release liner. Second Intelligent automated glue dispenser ensure the uniformity of the adhesive, which directly affects the adhesion and effectiveness of the dressing, ensuring that the dressing adheres firmly to the skin, providing stable protection for the wound. Dispensing at the edge seal prevents external bacteria, moisture, etc., from entering the inside of the dressing, maintaining the sterility and adhesion of the dressing.

Dispensing Requirements:Dispensing for medical dressings requires a high degree of uniformity and stability. Second Intelligent auto glue dispensing machine can be equipped with specialized coating devices, precisely controlling the adhesive flow rate and coating speed to achieve uniform dispensing over a large area, while also allowing flexible adjustments according to the different sizes and shapes of the dressings.

Desktop Rotary 4 Axis Automatic Benchtop Glue Dispensing Machine Robot SEC-E380R

4.Dispensing for Capsule Endoscopes

Dispensing Location and Function:Dispensing occurs at the outer shell seal and the fixing points of electronic components in capsule endoscopes. Second Intelligent automatic glue spraying machine prevent bodily digestive fluids from entering the capsule and damaging electronic components, ensuring that the capsule endoscope can function properly in the body and acquire clear image data. Dispensing for fixing electronic components ensures the positional stability of each component inside the capsule, avoiding component damage or displacement due to collisions during capsule movement, which would affect the performance of the endoscope.

Dispensing Requirements:Due to the small size and complex internal structure of capsule endoscopes, the precision requirements for automated dispensing machines are extremely high. Second Intelligent Desktop Dispensing Robot have micro-volume dispensing control and high-precision positioning capabilities, enabling accurate dispensing operations in confined spaces, ensuring that the adhesive provides good sealing and fixation without affecting other performance characteristics and functions of the capsule endoscope.

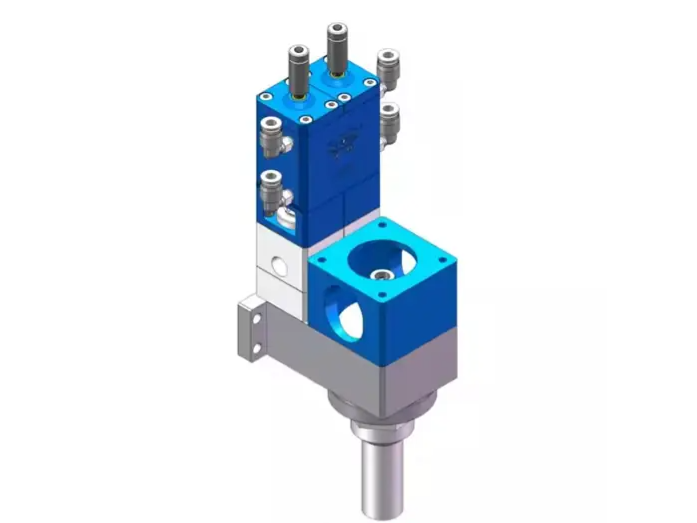

Glue Dispensing Valve

5.Dispensing in Other Medical Devices

In addition to the applications mentioned above, Second Intelligent adhesive dispensing systems are also widely used in the production of other medical devices such as surgical gowns, pacemakers, dialysis filters, and dental equipment. The manufacturing of these devices requires strict quality control, and the precision and reliability of dispensing machines directly affect the safety and functionality of the medical devices.

Second Intelligent dispensing machines provide comprehensive pre-sales, in-sales, and after-sales service, ensuring that customers receive timely technical support and maintenance during use, further enhancing their competitiveness in the pharmaceutical industry.