Applications of Fully Automatic Coating Machine Production Lines

Overview of the application fields of fully automatic coating machine production line, The fully automatic coating machine production line is a kind of efficient and precise automatic coating equipment, which is widely used in many industries such as electronics, automobiles, medical treatment, and new energy. It realizes high-precision and high-consistency coating operations through computer control, greatly improving production efficiency and product yield. The following is a detailed introduction to its main application fields.

1.Electronic manufacturing industry

(1) PCB (printed circuit board) coating

The fully automatic coating machine is used for three-proof paint (moisture-proof, anti-corrosion, and dust-proof) spraying in PCB manufacturing to protect the circuit board from environmental erosion and improve the reliability of electronic products.

(2) Semiconductor packaging

In the chip packaging process, the automatic Conformal coating machine is used for processes such as underfill and wafer-level packaging (WLP) to enhance the mechanical strength and heat dissipation performance of the chip.

(3) Display manufacturing

It is used for optical adhesive (OCA) coating and polarizer lamination of OLED/LCD screens to ensure the uniformity and bonding strength of the display panel.

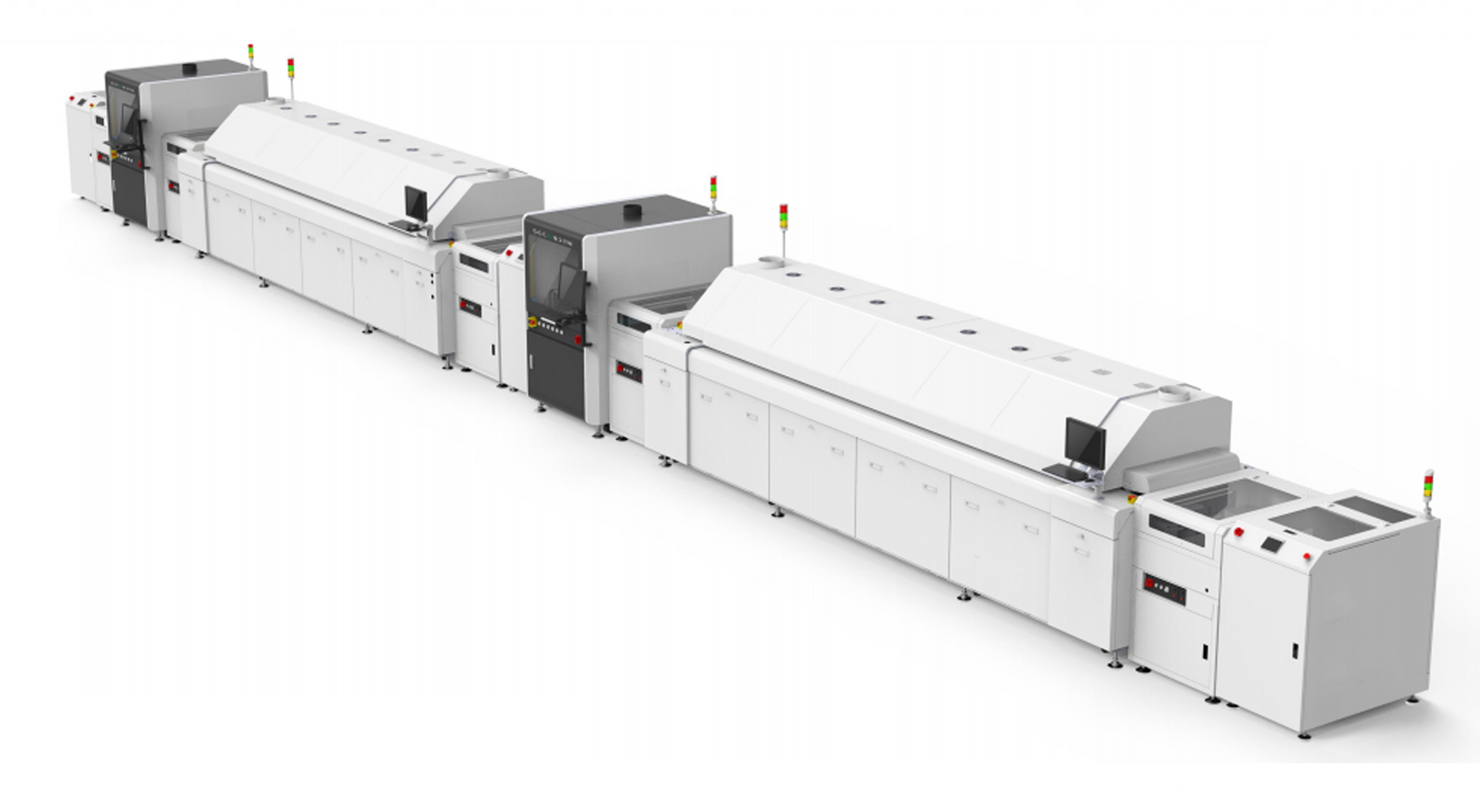

Fully automatic Conformal coating machine line

2.Automotive industry

(1) Automotive electronic coating

Key components such as automotive ECU (electronic control unit) and sensors require waterproof, shockproof and anti-corrosion coating. Fully automatic coating machines can accurately control the amount of glue to ensure long-term stability.

(2) Battery manufacturing (new energy vehicles)

In power battery production, Selective automatic coating machine line are used for electrode sheet coating (positive and negative electrode slurry), battery sealant coating, etc., which affects battery performance and safety.

Selective automatic coating machine line system solutions

(3) Body and parts painting

Some high-end cars use automated coating processes to accurately apply anti-corrosion coatings and sealants (such as windshield glue) to improve the durability of the car body.

3.Medical equipment industry

(1) Medical sensor coating

Medical electronic devices such as blood glucose meters and electrocardiogram electrodes need to be coated with biocompatible coatings to ensure safety and signal stability.

(2) Medical device packaging

Some implantable devices (such as pacemakers) require waterproof sealant coating to prevent body fluids from penetrating and affecting their functions.

(3) Drug sustained-release coating

In the pharmaceutical industry, coating machines can be used for tablet coating or medical catheter drug coating to control the drug release rate.

4.New Energy Industry

(1) Photovoltaic (Solar) Cell Coating

Used for backplane adhesive and encapsulation adhesive (EVA/POE) coating of solar panels, affecting the weather resistance and power generation efficiency of components.

(2) Hydrogen Fuel Cell Membrane Electrode Coating

The catalyst coating of proton exchange membrane (PEM) requires extremely high precision. Fully automatic coating machines can ensure uniformity and improve battery performance.

5.Consumer Electronics and Home Appliances

(1) Smartphones/Tablets

Used for waterproof sealant and structural adhesive coating, such as mobile phone frame bonding and waterproof receiver mesh coating.

(2) Home Appliance Manufacturing

Such as heat insulation foam adhesive coating of refrigerators and air conditioners, or three-proof paint spraying of circuit boards, to improve product durability.

6.Aerospace and Military Industry

(1) Avionics Equipment Protection

Aircraft avionics systems require mildew and salt spray coating to adapt to extreme environments.

(2) Composite Material Bonding

The bonding of carbon fiber composite materials for aircraft fuselages and satellite components relies on high-precision glue coating to ensure structural strength.

Conclusion

The fully automatic coating machine production line has become one of the core equipment of modern manufacturing industry with its advantages of high precision, high efficiency and programmable control. With the advancement of Industry 4.0 and intelligent manufacturing, its application field will be further expanded to cover more high value-added industries.

Does your industry need coating solutions? Welcome to discuss further!

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.