Second Intelligent Automotive Dispensing Machine: Intelligent Transformation Tool for Manufacturing Industry

In the wave of manufacturing in the 21st century, intelligence and automation have become the inevitable trend of industry development. With the rapid development of automobile manufacturing industry, the requirements of automobile parts on precision and efficiency are increasing, the traditional manual or semi-automatic dispensing equipment has been difficult to meet the needs of modern production.

Second Intelligent, as a glue dispenser machine industry leader, with its innovative products and solutions, in the field of automotive manufacturing shine, for the intelligent transformation of the manufacturing industry to provide strong support.

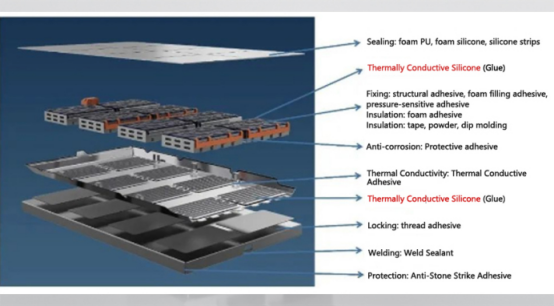

As a key equipment in modern automotive manufacturing, Second Intelligent automotive glue dispensing machine is widely used in engine parts, body parts, chassis parts, electronic equipment, interior/exterior parts and other aspects. In the manufacturing process of engine parts, cylinder head, oil sump and other parts need to be sealed and fixed.

Second Intelligent automotive dispensers can precisely control the position and amount of glue applied to ensure the sealing and firmness of these parts, thus improving the performance of the engine and extending its service life.

In the manufacture of body parts, the assembly of doors, windows, roofs and other parts requires glue application operations to enhance the connection strength and sealing between the parts. With its high precision and flexibility, Second Intelligent’s automotive dispenser can adapt to body parts of different shapes and sizes, achieving precise gluing operations that

Ensure the integrity and safety of the bodywork. This feature is also reflected in the manufacturing process of chassis components. The assembly of key components such as suspension system and braking system also requires gluing operations to ensure the stability and safety of the system.

With the increase of automotive electronics, electronic devices such as sensors and controllers need to be encapsulated during the manufacturing process to protect the internal circuits and components. Second Intelligent automotive dispenser can precisely control the position and amount of glue application to ensure the sealing and reliability of electronic equipment encapsulation.

This improves the performance and stability of automotive electronic devices. In addition, dispensers also play an important role in the manufacturing of interior/exterior components. The assembly of interior parts such as seats, instrument panels, door panels, and exterior parts such as lights, bumpers, and emblems requires the bonding of various materials.

Second Intelligent automotive dispenser can ensure strong bonding and beautiful appearance of interior parts, which improves the comfort and overall quality of the car.

Second Intelligent automotive dispenser not only excels in hardware equipment, but also makes breakthroughs in technological innovation. The company has launched a number of fully automatic dispensers, such as FPC-NTC-CCS dispenser, SEC-E380 Benchtop Desktop Glue Dispenser Robot, etc., which have won wide recognition in the market for their high precision, high efficiency and high stability. These machines are equipped with advanced CCD visual positioning system, which realises precise identification and positioning of product position through high-definition camera and image processing algorithm, effectively avoiding errors caused by human factors. At the same time, the equipment also has an automatic correction function, which can adjust the position and angle of the dispensing head in real time to ensure the consistency and stability of the dispensing effect.

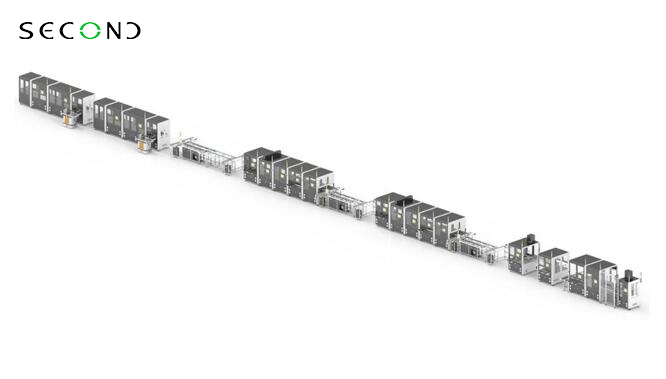

Second Intelligent New Energy/ Single-cell complete plant production line

In practical applications, Second Intelligent automotive dispensers have been widely used in the auto parts industry. For example, in the project of a professional manufacturer of automotive electronic OBC, Second Intelligent Intelligent successfully won the bid and provided more than 30 dispensers for its 10 dispensing and board loading lines, which further improved the production efficiency and

This project further improved the production efficiency, met the customer’s demand for production capacity, and ensured the stability of product quality. The successful implementation of this project fully demonstrates the professional strength and technical advantages of Second Intelligent in the auto parts industry.

Looking to the future, Second Intelligent will continue to adhere to the ‘innovation, pragmatic, efficient, excellent’ spirit of enterprise, and constantly increase R & D investment and technological innovation, to promote the technological upgrading and product optimisation of online automatic dispensing equipment. At the same time, Second Intelligent will strengthen the cooperation and communication with the upstream and downstream enterprises in the industry, and jointly promote the development of fluid control technology.

Together, we will promote the development and application of fluid control technology, and provide strong support for the high-quality development of the auto parts industry.