Achievements of Second Intelligent Equipment in Dam Sealing Dispensing Applications

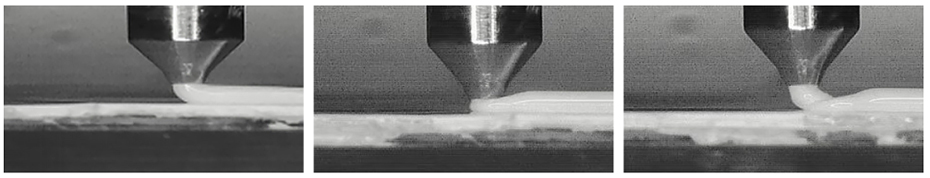

Dam sealing dispensing is a high-precision dispensing technique used in electronic packaging and other industrial applications, primarily aimed at preventing liquid material leakage and providing structural support.

Dam sealing dispensing involves applying adhesive in specific areas to create a fixed dam structure, which prevents adhesive overflow and ensures precision and effectiveness in dispensing. Dam sealing adhesives are typically categorized into two types:

Single-component dam sealing adhesive: Easy to use and ready for immediate application.

Second Intelligent Equipment Co., Ltd. offers single-component dispensing machines that are easy to program and operate, featuring the following characteristics to better meet customer demands for dispensing processes:

1.The platform and X/Y module bases are made using mineral casting, with critical surfaces processed by grinding to ensure higher precision and stability.

2.A gantry structure allows for high load-bearing capacity and structural stability.

3.A powerful vision positioning system supports Mark point positioning, edge detection, and 3D scanning positioning.

4.Strong expandability enables the addition of functions such as AOI inspection, 3D detection, and UV exposure curing.

5.Excellent platform compatibility allows for both contact and non-contact dispensing, catering to various products and processes.

6.Replaceable stainless steel housing meets Class 100 cleanroom requirements.

Single Component Dispensing Machine SEC-400DL

Two-component dam sealing adhesive: Requires uniform mixing of the two components before use, suitable for more complex application scenarios.

Second’s unique motion controller, combined with advanced algorithms, achieves high-speed and precise three-dimensional motion. By precisely controlling the metering motor, it ensures accurate ratio, automatic mixing, and automatic dispensing of two-component adhesives.

In addition, it offers the following advantages:

1.Equipped with vacuum feeding and vacuum degassing, with optional features such as heating, stirring, automatic cleaning, and pressure monitoring, capable of handling various complex adhesive environments.

2.A stable operating system with a user-friendly interface and high cost-effectiveness!

Featuring a three-axis motion platform and Second’s proprietary control software, it can follow predefined trajectories such as points, lines, circles, and arcs while automatically achieving the ratio and mixing of two-component adhesives. The system also includes vacuum feeding, vacuum degassing, with optional stirring, heating, automatic cleaning, and pressure monitoring functions. The simple operation significantly saves manual mixing time, enhances efficiency, reduces costs, and improves cost-effectiveness!

Automatic Potting Machine SEC-S3030-C

Second Intelligent dam sealing dispensing machines are widely used in multiple fields, including:

Electronic Packaging: Used for integrated circuits, LED packaging, sensors, etc., ensuring the sealing and protection of electronic components.

Semiconductor Manufacturing: Forms insulating barriers in wafer-level packaging to prevent signal interference.

Optical Devices: Secures lens positions and prevents adhesive overflow from contaminating optical surfaces.

The dam sealing dispensing process has the following advantages:

● High Precision: Achieves micron-level accuracy, suitable for fine dispensing.

● High Efficiency: Supports automated production with rapid curing.

● Strong Chemical Stability: Resistant to acids, alkalis, solvents, and high-temperature, high-humidity environments, showcasing strong adaptability.

● High Mechanical Strength: Provides good structural support, preventing delamination and cracking.

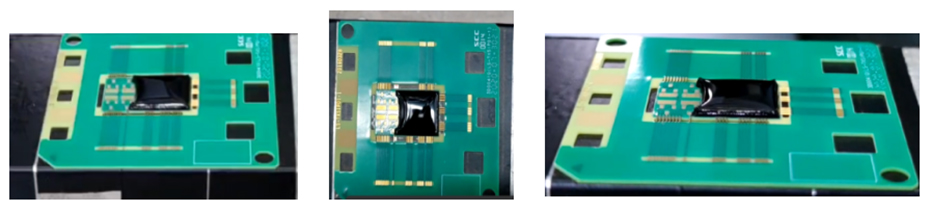

Dam sealing adhesive, also known as chip dam sealing adhesive or dam filling adhesive dispensing machine in PCB boards, is a specialized material used for encapsulation and filling of electronic components. It possesses moisture-proof, waterproof, and weather-resistant aging characteristics and can withstand high temperatures of up to 260°C. Dam sealing adhesive is a single-component material with high viscosity and strong bonding strength, primarily used for filling and encapsulating, making it an essential material for IC chip encapsulation.

Dam sealing adhesive can be used for bare chip gold wire encapsulation and cavity filling, as well as chip encapsulation on lead frames, ceramic substrates, PCB boards, and FPC boards, protecting the encapsulated glue of chips and gold wires. This adhesive exhibits excellent aging resistance and good chemical stability, making it suitable for various application scenarios.

In PCB boards, typical applications of dam sealing adhesive include fixing and encapsulating bare chips after wire soldering, such as BGA and IC memory cards, ceramic packaging, and flexible circuit flip-chip bonding and encapsulation. The curing time for single-component dam sealing adhesive is typically 90 minutes at 100°C or 60 minutes at 120°C.

Shenzhen Second Intelligent Equipment Co., Ltd. (referred to as Second Intelligent) was established in 2006 and is a leading professional manufacturer and service provider of intelligent equipment in China. Our business scope covers numerous fields, including 3C, semiconductors, automotive electronics, lithium batteries, hydrogen energy, biomedical, and aerospace; our products include specialized fluid application equipment, industrial robot integration applications, hydrogen energy intelligent equipment, and critical components. We encourage clients with related needs to contact us promptly, and we will provide a professional technical service team to assist you throughout the process.