Dispensing, Coating, and Their Applications with Plasma Cleaning

Dispensing and coating processes are widely used in manufacturing, while plasma cleaning serves as a critical pre-treatment step, significantly enhancing their quality and reliability. Plasma cleaning creates an ideal substrate environment for dispensing and coating by activating surfaces, removing contaminants, and increasing surface energy.

Key Applications of Plasma Cleaning for Dispensing and Coating:

1.Improved Adhesion Strength and Reliability:

Problem: Substrate surfaces (e.g., plastic, metal, ceramic, glass) may have trace organic contaminants, oils, oxides, or release agents that hinder effective wetting and chemical bonding of adhesives/coatings. This leads to weak bonds, cold joints, coating delamination, and interfacial failure.

Plasma Action: High-energy particles in the plasma bombard the surface, effectively removing microscopic contaminants (organic and inorganic). Simultaneously, plasma activates the surface, introducing polar functional groups (e.g., hydroxyl, carboxyl, amino groups), significantly increasing surface energy.

Effect: The treated surface becomes hydrophilic and highly active. Adhesives or coatings spread better (reduced contact angle), forming tighter physical contact and stronger chemical bonds (covalent, hydrogen bonds) with the substrate. This dramatically improves bond strength, sealing integrity, and long-term reliability. It’s crucial in microelectronics packaging (e.g., die attach, underfill), automotive sensor bonding, and medical device assembly.

2.Enhanced Wettability and Spreadability:

Problem: Low-surface-energy materials (e.g., engineering plastics like PP, PE, PTFE, PET) are inherently hydrophobic. Adhesives and coatings struggle to spread uniformly, often forming beads, pinholes, or uneven coverage.

Plasma Action: Plasma cleaning significantly increases the surface energy of these materials, transforming them from hydrophobic to hydrophilic. A hydrophilic surface promotes wetting by liquids (adhesives, paints, inks).

Effect: Dispensed dots and coatings spread more uniformly and smoothly across the substrate, reducing defects (e.g., voids, bubbles, edge pullback). This achieves more consistent, thinner adhesive/coating layers, improving appearance and functional performance (e.g., uniformity of conductive coatings, continuity of sealants). Vital for precision dispensing (e.g., smartphone bezel bonding, camera module assembly) and coating of optical elements (e.g., AR/VR lenses) or flexible circuit board protective layers.

3.Increased Coating/Plating Adhesion:

Problem: Weak boundary layers on substrate surfaces prior to spraying, electroplating, PVD/CVD, or conformal coating can cause poor coating adhesion, leading to blistering or peeling.

Plasma Action: Thoroughly cleans the surface, removing contaminants blocking direct contact between the coating and substrate. Surface activation provides more bonding sites.

Effect: Significantly improves the adhesion of subsequent spray paints, conformal coatings, metal platings, and optical coatings to the substrate, ensuring long-term stability and protective performance. Applied in automotive parts pre-paint treatment, PCB conformal coating pre-treatment, and decorative plating pre-treatment.

Fully automatic Conformal coating machine line

4.Enabling Reliable Dispensing/Coating in Micro-Features and Complex Geometries:

Problem: In microelectronics packaging, MEMS devices, and microfluidics, dispensing/coating areas are extremely small (e.g., chip edges, microchannels) or geometrically complex (e.g., deep holes, narrow gaps). Contamination and poor wetting prevent effective filling or reliable coverage.

Plasma Action: Plasma cleaning offers excellent penetration, effectively cleaning and activating surfaces within these microscopic features.

Effect: Ensures adhesives fully wet and flow into fine gaps (e.g., underfill encapsulating BGA solder balls), and coatings uniformly cover complex 3D structures (internal and external surfaces). Enables high-precision sealing, protection, and bonding.

5.Replacing or Reducing Harmful Chemical Cleaners:

Problem: Traditional chemical cleaning (e.g., solvent wiping, acid etching) often uses toxic, flammable, volatile organic compounds (VOCs), posing environmental, safety, and health risks. It may also require drying and leave residues.

Plasma Action: Plasma cleaning is a dry, environmentally friendly physico-chemical process using inert gases (e.g., Ar) or reactive gases (e.g., O₂, air). It’s residue-free.

Effect: Provides a safer, greener, and more easily automatable pre-treatment solution, complying with increasingly stringent environmental regulations.

Key Application Areas:

a.Microelectronics Packaging & Assembly: Die attach, underfill, dam and fill, encapsulation, SMT component reinforcement, Flip Chip underfill, COB packaging.

b.Automotive Electronics: Sensor bonding & packaging, ECU module potting, headlight bonding/sealing, camera module assembly, BMS bonding & coating.

c.Medical Devices: Biosensor manufacturing, catheter bonding & coating, implantable device encapsulation, microfluidic chip bonding & channel treatment, diagnostic device assembly.

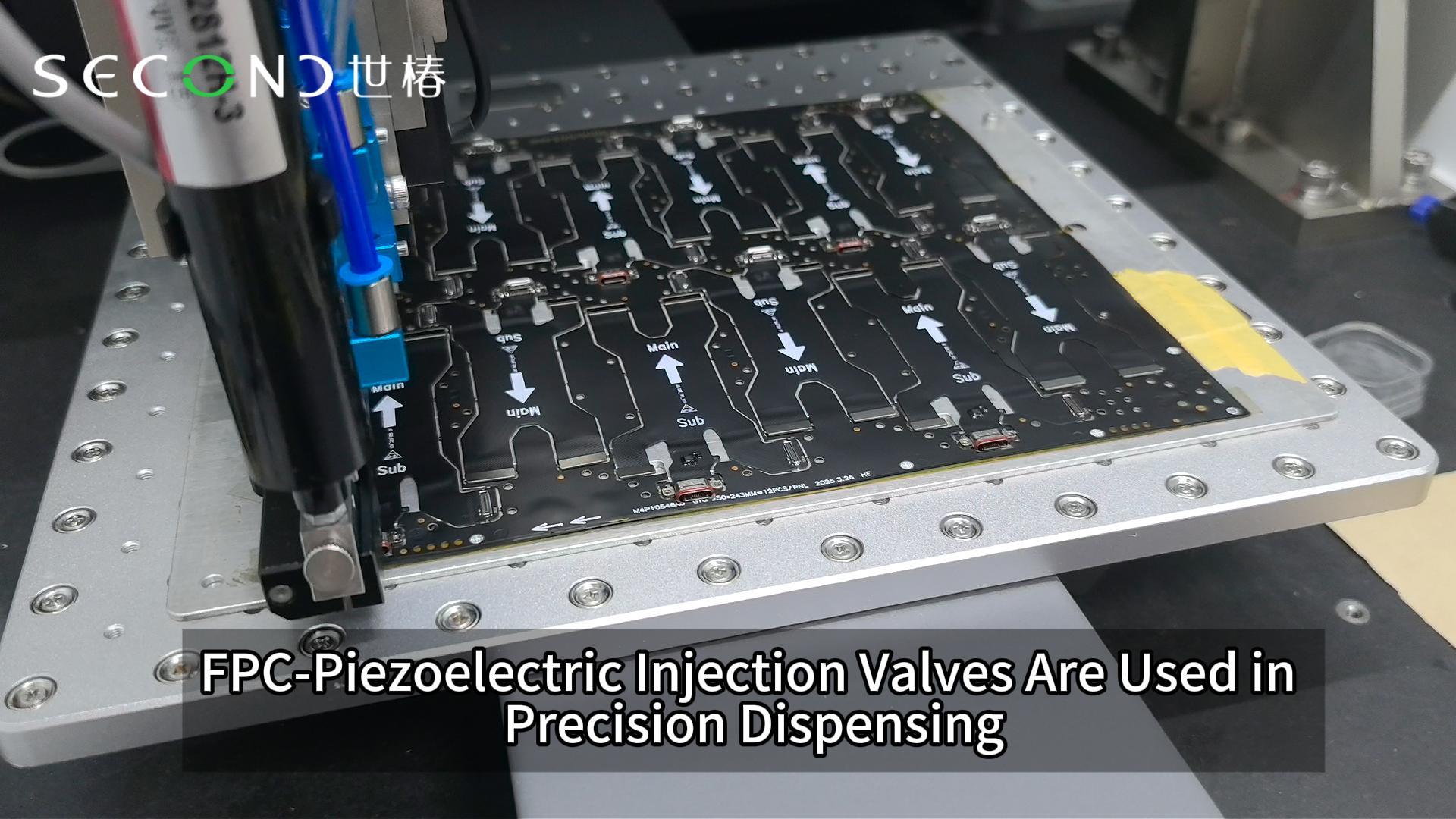

d.Consumer Electronics: Bonding in smartphones/tablets/wearables (screens, bezels, lenses), speaker diaphragm coating, microphone encapsulation, FPC protective coating.

e.Optoelectronics & Displays: Camera lens bonding & coating, LED packaging, pre-treatment for optical component (lenses, filters) coating, display module assembly.

f.Aerospace: High-reliability electronic component potting & coating, pre-treatment for structural bonding of composites.

g.Industrial Equipment: Precision instrument assembly bonding, sensor manufacturing & packaging, sealant coating.

SMT automatic glue dispenser SEC-DH600L

Second Intelligent high precision smt automatic glue dispenser machine apply epoxy resin to the bottom of the PCB board for underfill

Second Intelligent smt automatic glue dispenser automation SEC-DH600L has the following advantages:

● CCD visual programming precise positioning, visual correction, improve programming efficiency and dispensing accuracy;

● Chinese and English operating system, the software interface layout is clear, the operation is simple, easy to learn and understand;

● Support visual inspection, integrated control of dispensing and visual inspection, multi-purpose machine, effective control of dispensing yield;

● It can be equipped with a lin e laser scanner for 3D path guidance and flexible dispensing;

● The software can support a variety of dispensing systems and functional module applications, such as automatic needle alignment, automatic

height measurement, dispensing weighing compensation, five-axis linkage and other functions, which can effectively overcome the difficulties of

various dispensing processes and help improve quality;

Technical Considerations:

a.Process Sequence: Plasma cleaning must be performed immediately before dispensing or coating. The activated surface loses effectiveness over time (“aging effect”), ideally requiring the next step within hours (or even minutes for high-demand applications).

b.Process Optimization: Cleaning efficacy depends on parameters like gas type, power, time, and chamber pressure, requiring optimization for specific substrates and contaminants.

c.Equipment Selection: Based on part size, shape, and volume, choose vacuum plasma cleaners (superior results, suitable for complex parts/high demands) or atmospheric plasma cleaners (inline processing, suitable for flat/simple curved surfaces).

Conclusion:

Plasma cleaning is an indispensable “enabler” for dispensing and coating processes. By deeply cleaning and effectively activating substrate surfaces, it addresses the core causes of bonding/coating failure – interfacial contamination and weak bonding forces. The result is a significant improvement in the quality, reliability, consistency, and yield of dispensing and coating processes, especially in demanding fields like precision electronics, medical devices, and automotive manufacturing. For manufacturing processes pursuing high performance and reliability, incorporating plasma cleaning before dispensing/coating is often a critical success factor.

[contact-form-7 id=”5″ title=”Contact form 1″]