Dispensing machine:Frequently Asked Questions and Answers about Customers

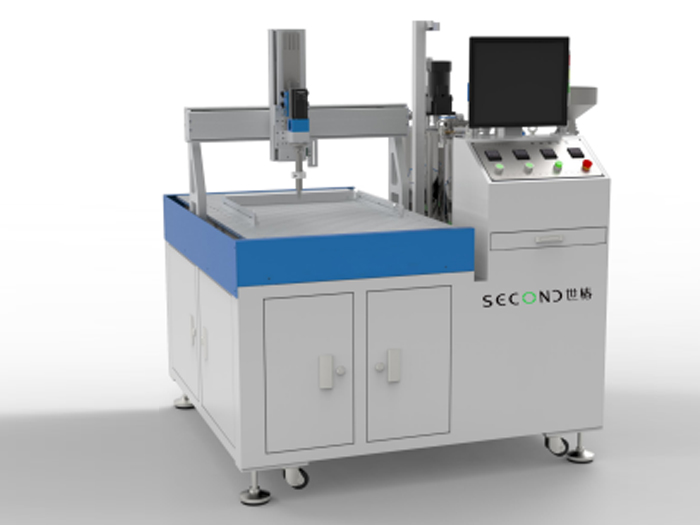

Q1: What is a automated dispensing machine?

A: It’s an automated device for precise fluid application (e.g., adhesives, sealants) in manufacturing, widely used in electronics, EVs, and medical devices.

Q2: What industries do Second Intelligent‘s machines serve?

A: 3C electronics, EV batteries, LED packaging, solar panels, and biomedical devices.

Q3: What’s the positioning accuracy of Second Intelligent dispensers?

A: ±0.01mm (with linear motors), ensuring micron-level repeatability for miniaturized components.

Q4: How to handle high-viscosity fluids (e.g., epoxy)?

A: Our pumps support 1,000,000cP viscosity with heated barrels (up to 100°C) and pressure relief valves.

Q5: Can it dispense multiple materials simultaneously?

A: Yes. Dual-fluid models with 1:0.8~1:1.2 mixing ratio control are available.

Q6: What’s the minimum dot size achievable?

A: 0.1mm diameter with ultra-fine nozzles (requires low-viscosity fluids).

Q7: How to prevent clogging?

A: Self-cleaning nozzles + pneumatic purging system(Optionally available).

Q8: Is the machine compatible with Industry 4.0?

A: Yes. Supports OPC UA/MQTT protocols for real-time data integration with MES/ERP.

Q9: What’s the warranty period?

A: 2 years for core components (motors, controllers), 1 year for whole machine.

Q10: How to resolve material waste?

A: “Suck-back” function retracts residual fluid, saving 5~8% material per cycle.

Q11: Can it adapt to curved surfaces? /

A: 6-axis robotic arms (optional) enable 3D path dispensing on irregular shapes.

Q12: What certifications do the machines have?

A: CE, UL, ISO 9001, and RoHS compliance for global markets.

Q13: How long does setup take?

A: Pre-configured parameters allow <4 hours for common applications (e.g., PCB coating).

Q14: Is training provided?

A: Free 3-day onsite training + 24/7 remote guidance.

Q15: How to handle abrasive fillers?

A: Tungsten carbide nozzles and hardened plungers extend lifespan by 3x.

Q16: What’s the max throughput?

A: 12,000 dots/hour (with high-speed linear motors).

Q17: Can it store process recipes?

A: 200+ recipes storage with QR code quick-call function.

Q18: How to ensure environmental safety?

A: VOC filtration modules (optional) reduce solvent emissions by 90%.

Q19: What if power fails mid-process?

A: Emergency recovery mode resumes dispensing from breakpoint automatically.

Q20: How to order spare parts?

A:We have specialised spare parts personnel to provide you with a more efficient service.