Empowering lithium battery production line, revealing Second Intelligent’s “smart” engine

● New Energy Power Battery Core Coating Project ●

Thanks to the explosive development of the new energy automobile industry, the lithium battery also ushered in a period of rapid development. Shenzhen Second Intelligent Equipment Co., Ltd (Second Intelligent) lithium battery gluing machine equipment is based on the new energy lithium battery packaging section, through the core, side plate, end plate, insulating sheet, etc. to glue to achieve bonding, sealing, thermal conductivity and other functions, its performance requirements and stability have reached the international leading level.

In 2023, Second Intelligent provided more than 20 sets of gluing machine equipments for 3 production lines of a new energy power battery manufacturer, which helped it to further improve the production efficiency, meet the market demand for production capacity, and escort the stability of product quality, and helped the customer to rapidly expand the market share!

|Second Intelligent-Battery cell glue coating machine

New energy, new opportunities!

With the new energy vehicle market penetration rate continues to increase corresponds to the global power battery manufacturing continues to expand. Currently, the demand for power batteries is “blowout” explosive growth. Industry data predicts that the global electric vehicle sales of 23.3 million units in 2025, corresponding to the demand for power batteries amounted to 1,691GWh.

2021-2025 power battery demand CAGR of nearly 48%.

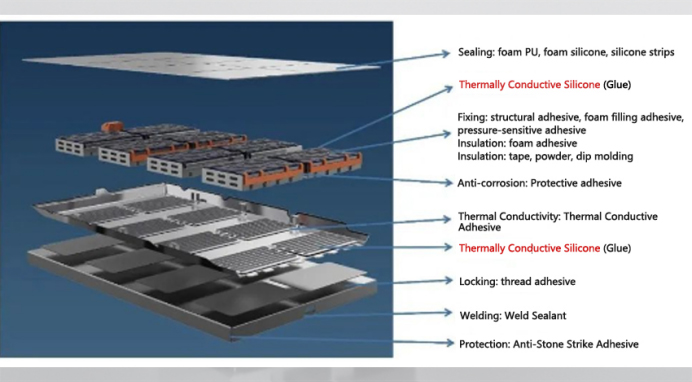

| Adhesive technology in the battery system application point

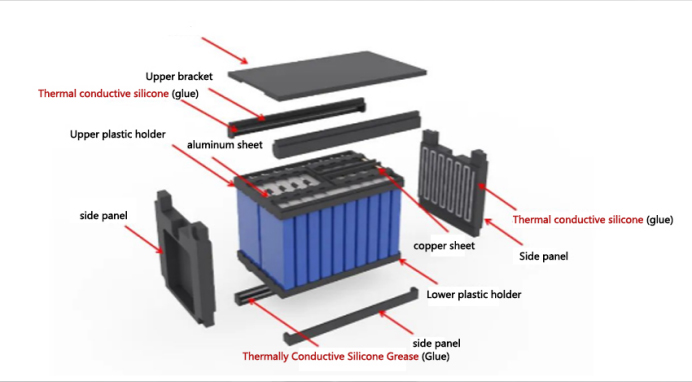

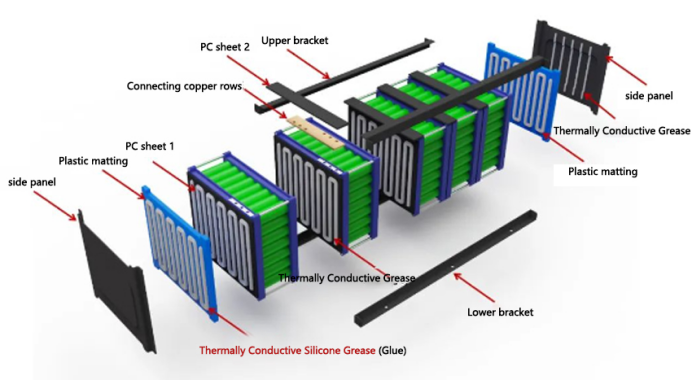

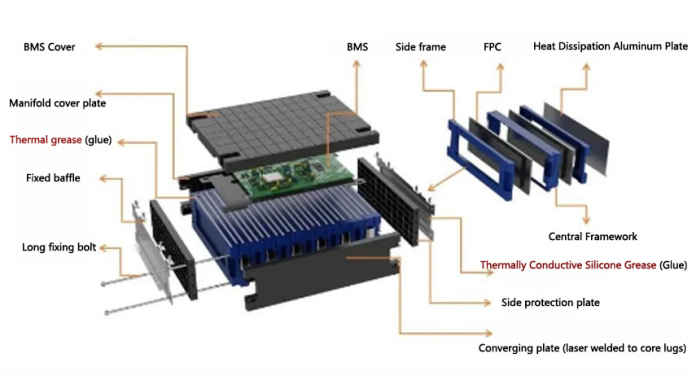

The power battery is the “heart” of new energy vehicles. It refers to the rechargeable battery system used in new energy vehicles to provide power sources. The battery cell is the smallest unit of a battery system. Multiple battery cells form a module, and multiple modules form a battery pack. This is the basic structure of automotive power batteries.

| Square Core Module

| Cylindrical Core Module

| Soft pack battery module

Behind the rapid development of the industry is the continuous technological refinement of the manufacturing process and supporting equipment. Among the many key processes and materials, new energy power battery cell gluing as one of the most important processes in the assembly process, how to improve the precision of gluing,

Stability and automation has become the focus of industry attention.

To solve the reliability of new energy vehicle batteries, it is necessary to deal with the “core gluing” problem. Therefore, the well-known brands of new energy power battery cell suppliers in all aspects of the screening is very strict.

New energy power battery market demand soars, and lithium-ion coating machine as an important battery core production equipment, its market demand is also increasing. At present, in the domestic new energy automobile industry chain rapid development background, lithium-ion coating machine development trend is good.

| Choosing Second Intelligent to build new energy power battery cell coating project together

After seventeen years of technological precipitation and innovation, customizable solutions, professional design, fast delivery and excellent service, Second Intelligent has gradually established a brand image of high quality, credibility and service in the industry. Against this background, the new energy power battery manufacturer finally chose Second Intelligent.

The new energy power battery manufacturer finally selected Second Intelligent as the new energy power battery core coating supplier, the two sides of the team strong combination, around the site environment and process technology needs, from the early equipment program planning to the late equipment on-line always maintain close communication and cooperation.

Since December 2022, after receiving the customer’s new energy power battery cell coating project procurement needs, the team composed of R&D, engineering, after-sales, project and sales of Second Intelligent, responded to the customer’s needs in a timely manner, decomposed the customer’s needs, carried out product validation, and efficiently linked the functions of various sections within the company, closely communicated with the customer and finalized the program.

Communicate closely with the customer and finalize the details of the program. Second Intelligent team and customer team keep online meeting about 2 times a week to continuously optimize the solution design.

In March and April 2023, the equipment for this project was delivered in stages. Due to the imperfect supporting facilities of the manufacturer affected the commissioning time, Sechun technicians actively cooperated with the customer, overcame the difficulties with the customer, chased the progress, and compressed the commissioning time from the original plan of 1 month to 10 days. Due to the tight time,

Due to the tight time and heavy task, the technicians worked overtime and sprinted with all their strength, and finally the equipment was put into normal use according to the original date and the task was successfully completed. The debugging personnel stationed at the customer’s production site, set up night shift rotation, always focusing on the customer, and the spirit of continuous fighting were fully affirmed by the customer.

It shows the team spirit of hard work and excellence of Second Intelligentpeople.

This is not only due to the exploration and development of Second Intelligentteam, but also inseparable from the customer’s high trust to Second Intelligent. In the process of project communication between the two sides, the customer always encourages Second Intelligentteam to give full play to the technical advantages in the lithium equipment overall solutions for the new energy power battery core gluing process to provide new technology,

New ideas to solve the industry automation and industrialization problems. In the end, Second Intelligentalso lived up to the expectations, riding on the momentum to make progress, and completed the answer sheet with more than expected performance, and a number of innovative designs are more efficient compared with traditional solutions.

The new energy power battery manufacturer said that this is a very happy cooperation, Second Intelligentteam solved the glue production line problems that had been bothering for a long time, and the project also shines because of the power of mutual creation and prosperity, and we hope that the two sides can cooperate in more fields in the future.

| Technological innovation, help lithium industry high-quality development

The main body of this equipment consists of loading system, transfer system, feeding system, metering system, distribution system, etc., with the lack of material monitoring, pressure monitoring, flow monitoring and other functions, through software control and information management (MES system) into a glue raw material processing,

Through software control and information management (MES system), it becomes a gluing machine with the functions of raw material handling, precise metering and automatic mixing, with high stability and high precision, which effectively improves the overall production efficiency of the production line.

| Second Intelligent-Battery cell glue coating machine

The feeding system adopts a pressure plate pump, which can reliably transfer glue from the raw material drum to the transit tank. It has the following technical advantages: new NXT air motor for durability, less pulsation for uniform glue pattern; lowest initial investment cost, the system has reliable feeding capability;

High-quality shared parts reduce maintenance time, normal use time > 6 months; pump contains low level alarm, to low level automatic shutdown; integrated air control method, easy to operate, according to the needs of different sizes and materials of the pump body can be selected.

Metering system for high filler, highly abrasive materials, improve service life. Stable flow rate of glue discharge, high precision and repeatability. Pressure monitoring, through the control of the system pressure, to eliminate the beginning and end of the glue start and end point of the size of the head, line consistency is high; and can monitor the system pressure, high and low pressure alarm.

Pump body structure design, reduce dead space, into the glue out of the basic push through, to prevent glue accumulation.

Mixing system using two-component dispensing mixing valve, dual cylinder control, can be individually controlled A/B, with a suction-back structure, no glue dripping, no pulling, no glue leakage after closing the valve. Universal dispensing head, can be matched with standard static mixing tube, with proportional dispensing head, easy to test the ratio.

The modular design of this gluing equipment facilitates the maintenance and repair of customers and saves the maintenance and repair cost. Repeatedly verified components and control programs to ensure the long-term stable operation of the equipment, improve the customer’s production capacity. 24-hour continuous production, no downtime for glue drum change, the equipment can be unmanned, reducing the customer’s labor costs. The real-time uploading of key parameters of the equipment provides strong support for the traceability of each product. Simple and clear control interface, easy-to-operate control mode, and perfect anti-dumbness and anti-error settings can be easily operated to avoid the loss caused by unfamiliar operation.

This cooperation marks the customer’s high recognition of the lithium equipment created by Second Intelligent, and also highlights the strong technical strength of Second Intelligent in the automated production and manufacturing of lithium equipment and rich process areas, which is an important demonstration and driving role for the company’s new energy power battery business promotion and expansion.

Second Intelligent sales elites also have confidence and ability to add bricks and mortar for more lithium industry production lines.

Second Intelligent gluing machine, used in lithium industry well-known brands, rapid breakthroughs in research and development and batch application in the market, casting Second Intelligent in the field of power battery gluing the leading position, for the subsequent expansion of more new energy power battery gluing projects and cooperation has strengthened a solid foundation. As an enabler of the new energy power battery industry chain, in line with the three major trends of the lithium equipment industry line, standardization and globalization, in the future, Second Intelligent Intelligence will pay close attention to the technological development of the new generation of batteries, and carry out product iteration in a timely manner in accordance with the requirements of the new process and new equipment, and continue to promote the innovative development of the lithium industry together with our partners and lead the industrial progress.