How to Achieve Ultra-Stable, High-Precision 120 C, 3,000cps Dispensing

Target Keywords: Hot Melt Temperature Control, Polyurethane Viscosity Control, 3M6316B Dispensing, High-Precision Heating System, Glue Dispensing System Accuracy

Introduction: Temperature – The Silent Killer of Precision Dispensing

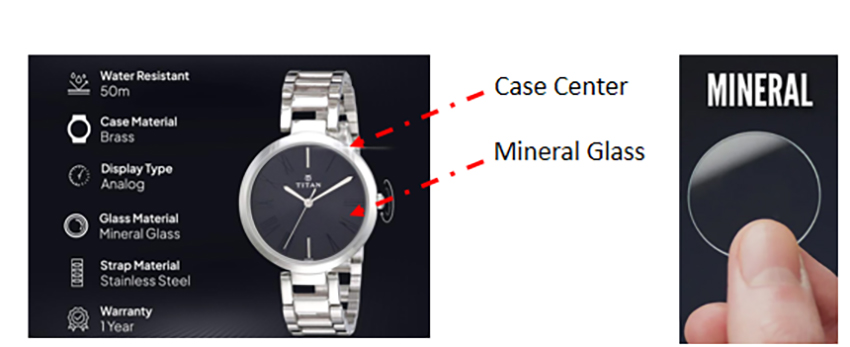

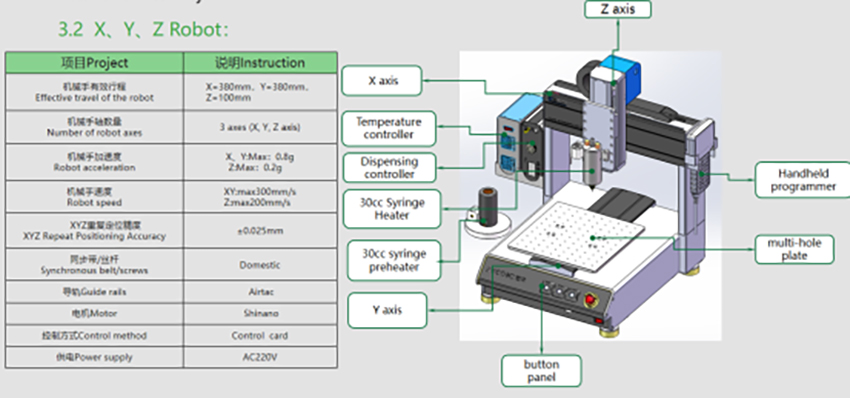

In precision manufacturing, processes like bonding the watch case center (Brass/Stainless Steel/Ceramic) to the Mineral Glass (MG) often rely on hot melt adhesives, such as the 3M6316B Polyurethane Adhesive. A critical characteristic of these glues is their requirement to be heated to high temperatures to reduce viscosity for dispensing.

However, temperature is the most common factor sabotaging the final product quality. Even minor deviations can lead to “waviness” in the glue line, inconsistent dispense volumes, or premature curing/degradation of the adhesive. Are you searching for a definitive solution to overcome the challenges of controlling high-temperature, high-viscosity adhesives?

Pain Point Focus: The Three Core Challenges of Hot Melt Dispensing

The problems you face are the exact reasons we engineered our solution:

Narrow Process Window: The 3M6316B glue needs to be dispensed at 120°C to achieve its optimal viscosity of 3,000cps. If the temperature drops to 110 °C, the viscosity spikes to 4,500cps. This lack of control compromises the stability required for applications like bonding the watch case.

Devastating Impact of Temperature Fluctuation on Accuracy: A minimal temperature swing in any part of the system—from the 30ml barrel to the dispensing needle (0.3mm inner diameter) —will cause the viscosity to deviate. This instantly undermines the consistency required to prevent waviness during the dispense process.

Risk of Uneven Heating: Conventional heating methods often fail to maintain a uniform temperature across the barrel, hoses, and dispense valve. Localized overheating can cause the glue to partially cure or degrade, potentially clogging the 0.3mm inner diameter precision needle.

Our Solution: 3M Adhesive System’s Three-Stage Precision Heating and Control Technology

To meet the rigorous temperature and viscosity demands of hot melt adhesives like 3M6316B, we have developed the innovative Three-Stage PID Precision Heating and Control Technology.

1.Multi-Zone Precision Temperature Control: Guaranteeing 120 °C at 3,000cps

Technical Core: We divide the adhesive path into three critical, independently controlled thermal zones: Storage (Barrel/Tank), Transfer (Hose/Line), and Dispense (Valve/Nozzle).

Control Advantage: Each zone is equipped with independent PID (Proportional-Integral-Derivative) controllers and high-accuracy sensors. This ensures that the temperature of the 3M6316B glue remains consistently at 120 ∘C as it moves from the 30ml barrel through to the 0.3mm needle. This constant temperature guarantees a stable 3,000cps viscosity , which is essential for a steady, precise dispense without creating any waviness.

2.Rapid Heat-Up Mechanism: Minimizing Production Wait Times

2.Rapid Heat-Up Mechanism: Minimizing Production Wait Times

Addressing Client Concerns: We understand the critical nature of the question: “How long it will take to reach the dispense temperature?” Time is money.

Performance Enhancement: By utilizing an optimized heating module with high-efficiency thermal transfer and precise power allocation, our system features a Rapid Heat-Up Mechanism. This ensures the system reaches the 120 °C dispensing temperature in the shortest possible time (Please contact us for specific lead times), drastically reducing machine start-up time and maximizing overall production efficiency.

3.Compatibility and Convenience: Perfect Fit for 30ml Standard Barrels

Seamless Integration: Our heating unit is precisely engineered to perfectly and uniformly heat the industry-standard 30ml thermoset cartridge used to store your 3M6316B adhesive.

Simplified Operation: The modular design simplifies the necessary day-to-day production precautions. This ease of maintenance and barrel changeover minimizes downtime, ensuring a smoother operation flow.

Conclusion: Choose Stability, Choose Quality

By choosing our Three-Stage Precision Heating and Control Technology, you are not just acquiring a dispensing machine; you are investing in a precise, stable, and highly efficient fluid control solution. It ensures that your most demanding bonding applications—such as joining Brass, Stainless Steel, Ceramic, and Mineral Glass —achieve the highest standards of accuracy, waterproof, and airtight properties.