As the core power device in power electronic equipment, the packaging reliability of IGBTs (Insulated Gate Bipolar Transistors) directly determines the lifespan and performance of the entire converter, frequency converter, or new energy equipment. Vacuum potting is a crucial step in the current IGBT module packaging process.

Below, I will provide you with a detailed analysis of application cases of IGBT vacuum potting lines, covering process value, typical production line structure, specific application examples, key challenges, and trends:

Ι.Why Must IGBT Modules Use Vacuum Potting?

Before potting, the internal components of the IGBT module (chip, bonding wires, substrate, etc.) are already assembled, but numerous voids remain. If silicone gel is directly poured in under normal pressure, air cannot be completely expelled, leading to:

1.Residual air bubbles: These form partial discharges, which can break down under high voltage, causing module failure.

2.Deteriorated thermal management: Air bubbles have extremely poor thermal conductivity, affecting chip heat dissipation, leading to increased junction temperature and shortened lifespan.

3.Uneven mechanical stress: The expansion and contraction of air bubbles during temperature cycling creates stress on the bonding wires, easily causing breakage.

4.Localized corrosion: Air bubbles may trap moisture, leading to long-term electrochemical corrosion.

In-line automated vacuum potting Production line, through injection and curing under negative pressure, can minimize air bubbles, ensuring the density, insulation, and thermal conductivity of the potting material.

Ⅱ.Material Preparation: The Uniformity of the Adhesive Itself is Fundamental

● Adhesive Selection and Pretreatment:

* Low Viscosity and High Flowability: Select a silicone gel with a suitable viscosity (typically between 1000-5000 mPa·s). Too low a viscosity leads to leakage, while too high a viscosity results in poor flowability, making it difficult to fill narrow gaps.

* Adhesive Preheating: Preheating the A/B component adhesive containers at a constant temperature (e.g., 30-40°C) before dispensing significantly reduces viscosity and improves flowability and wetting properties.

● Precision Mixing and Initial Degassing:

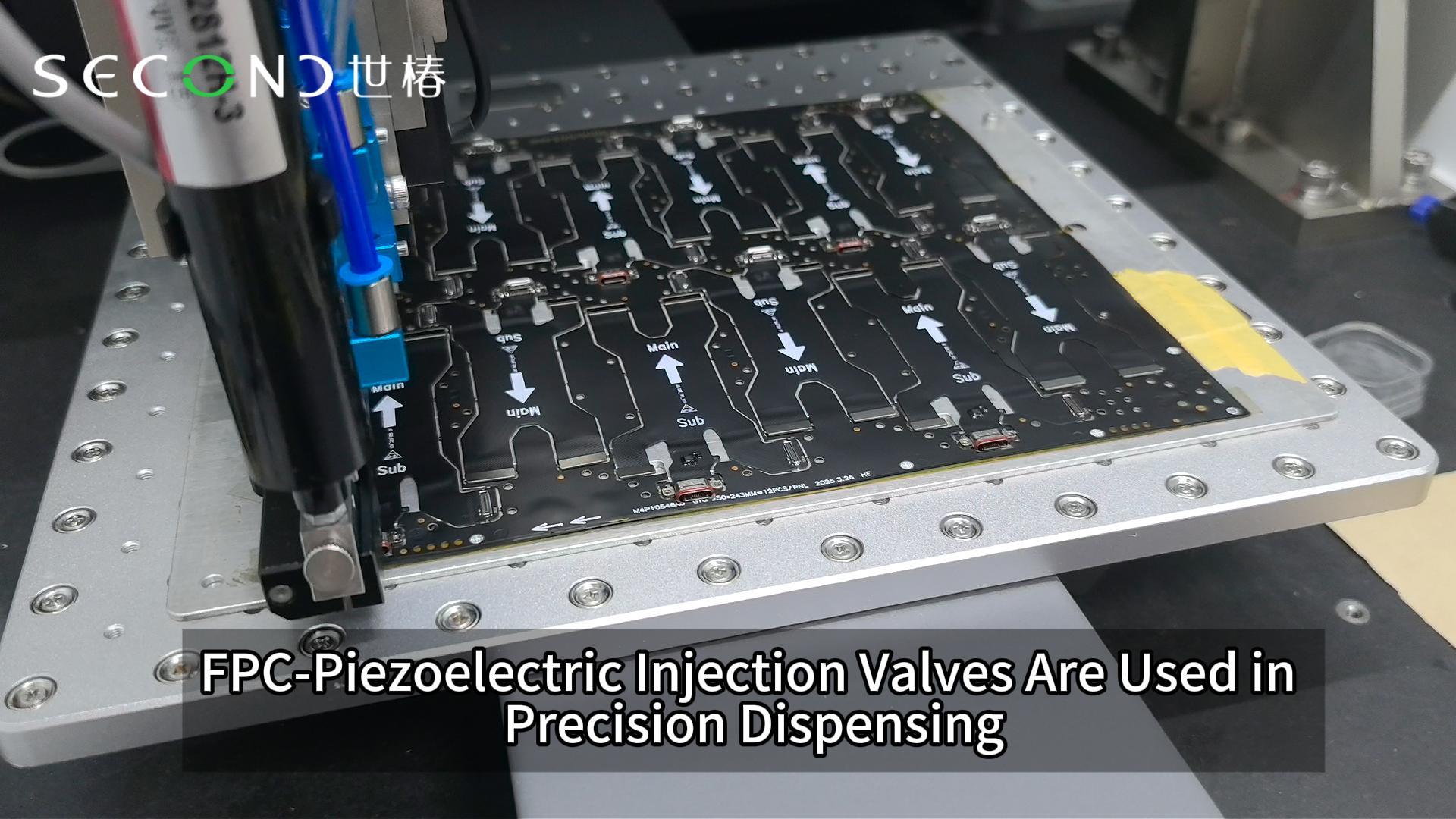

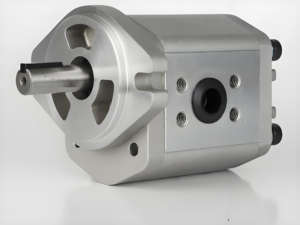

* Dynamic/Static Mixing: Use a high-precision gear pump for metering and achieve thorough and uniform mixing of components A/B through a dynamic mixing tube.

high-precision gear pump

* Initial Vacuum Degassing: Immediately after mixing, the adhesive enters a vacuum degassing tank. Under negative pressure, air bubbles trapped during mixing are removed, ensuring that the adhesive injected into the cavity is a uniform, bubble-free “substrate.”

Ⅲ. Typical IGBT Vacuum Potting Production Line Composition

A complete automated vacuum potting line is not a single piece of equipment, but a system integration. The core workstations are as follows:

1.Loading and Preheating Workstation:

IGBT Vacuum Potting Line SEC-S300-ZL

2.Vacuum Mixing and Degassing Station:

Function: Performs high-precision metering and mixing of two-component silicone gel (usually addition-type silicone gel). Immediately after mixing, a first vacuum degassing step is performed to remove air bubbles introduced during mixing. This is a prerequisite for ensuring adhesive quality.

3.Vacuum Potting Station (Core):

Function: Evacuates the entire potting chamber to a high vacuum (typically ≤1 mbar or even lower). Under vacuum, the degassed adhesive is injected into the module housing through a needle valve or dispensing head. The injection process can be completed under vacuum, or the vacuum can be maintained for a period after injection to allow air bubbles to escape fully.

4.Atmospheric Pressure Curing and Gel Station:

Function: After potting, the module is transferred to an atmospheric pressure, temperature-controlled curing tunnel or oven. The silicone gel first gels and sets at a low temperature (e.g., 80-100°C), and then fully cures at a higher temperature.

5.Material Unloading and Inspection Station:

Function: Automated material unloading, and may integrate ultrasonic scanning (C-SAM) or X-ray inspection for 100% non-destructive testing of the potting layer for defects such as bubbles and delamination.

6.Central Control System (MES):

Function: Controls the overall production line cycle time, records process parameters (vacuum, temperature, glue volume, time, etc.) for each module, and enables full traceability. This is crucial for meeting the high quality control requirements of industries such as automotive electronics.

Vacuum potting technology

Inline vacuum potting machine: For example, the SEC-S400-ZL/ZHL ensures no air bubbles remain in the adhesive during potting through rapid vacuum extraction and high sealing performance, reducing leakage caused by bubbles.

Ⅳ. Specific Application Industry Cases

Case 1: New Energy Vehicle Electric Drive Controller (Inverter)

Module Type: Large IGBT modules or SiC modules such as HP1, HP2, and HP3 used in the main inverter of new energy vehicles.

Process Challenges:

Extremely high reliability requirements: Must meet automotive-grade standards such as AEC-Q200 and withstand severe temperature shocks and vibrations.

High power density: Complex internal structure and narrow gaps in the module require good adhesive flow and complete filling.

Zero-defect target: Any internal air bubbles can cause fatal malfunctions during vehicle operation.

Pouring line application: Fully automated, high-vacuum potting lines are standard. The MES system ensures that data for each module is traceable to the vehicle’s VIN code.

Case 2: Photovoltaic/Energy Storage Converter (PCS)

Module Type: Medium-power IGBT modules.

Process Challenges:

Long-term outdoor operation: Must withstand high and low temperatures, ultraviolet radiation, and humid environments; high requirements for the weather resistance and insulation of the adhesive.

Cost-sensitive: While ensuring quality, higher production cycle time and efficiency are required.

Applications of the potting line: Semi-automatic or automatic vacuum potting systems are commonly used, offering high capacity and stability. Strict vacuum level requirements are also necessary.

Summary:

IGBT vacuum potting lines represent a crucial “precision protection” step in the power electronics manufacturing industry. It is no longer simply about “filling,” but a core manufacturing process ensuring the safe, reliable, and long-term operation of power modules in harsh environments. With the rapid development of electric vehicles and new energy power generation, the demand for high-efficiency, high-reliability, and fully automated vacuum potting lines will continue to grow, and their technology and application cases will continue to deepen and expand.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.

[contact-form-7 id=”5″ title=”Contact form 1″]