In precision manufacturing sectors such as electronics, automotive parts, and medical devices, fluid application equipment like dispensing machines, coating machines, and potting machines are crucial for achieving core processes such as product sealing, fixing, and insulation. With the deepening of intelligent manufacturing and Industry 4.0, MES (Manufacturing Execution System), situated in the middle layer of enterprise information system architecture, has become a key bridge connecting ERP/PLM above and field devices and automation systems (PLCs, dispensing machines, testing equipment, etc.) below . Through deep integration and efficient interaction with fluid equipment, MES enables transparent control, precise scheduling, and full-process traceability of the production process, significantly improving production efficiency and quality control.

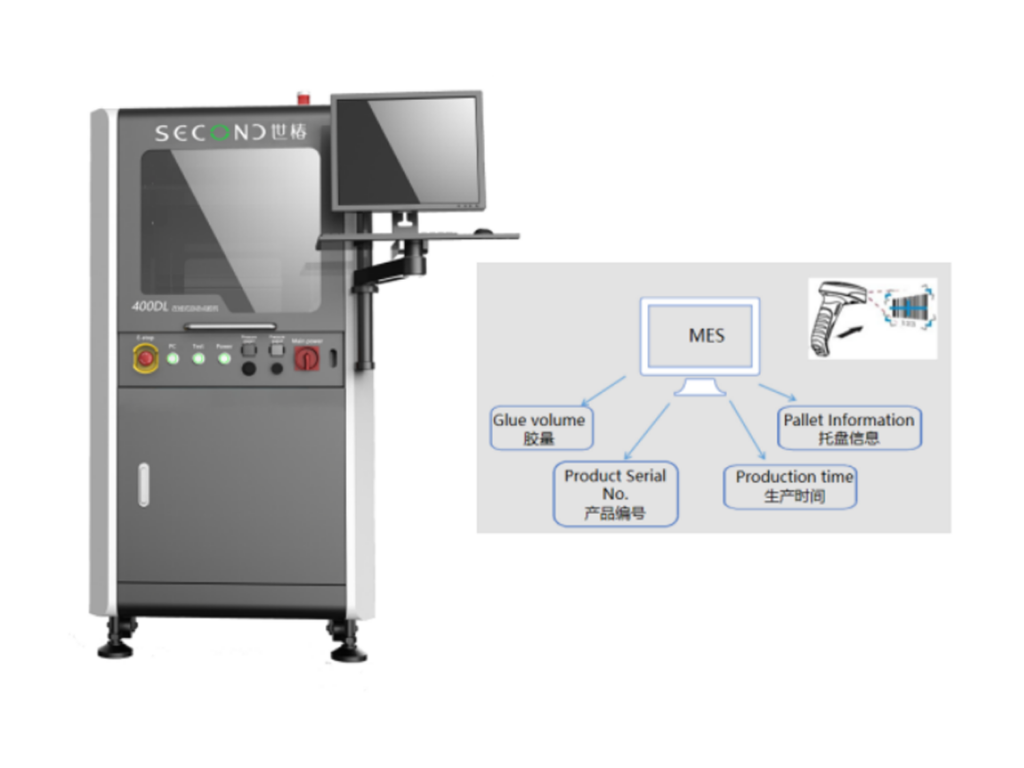

Second Intelligent Dispensing Machines, Dispensing Machines, and Coating Machines can all be customized with MES functions, and have successfully completed MES system integration and deployment with large enterprises such as BYD. For more technical details,welcome to contact our technical support department.

Ι.Core Functions and Interaction Processes of the MES System

Ι.Core Functions and Interaction Processes of the MES System

MES, or Manufacturing Execution System, aims to digitize, make traceable, controllable, and optimizable the production process . Its functions cover the entire production chain, forming a closed loop based on the logic of “planning-execution-monitoring-analysis-optimization,” providing comprehensive support for fluid equipment operations.

(I) Core Functional Modules

1.Production Planning and Scheduling : As the “command center” of the system, it receives macro orders from ERP, and combines factors such as fluid equipment capacity, personnel skills, material availability, and process constraints to break down orders into process-level tasks, generate accurate scheduling plans, and issue them to the corresponding equipment. It also supports dynamic rescheduling in abnormal scenarios such as emergency order insertion and equipment failure to avoid resource idleness or task conflicts.

2.Resource Management : Overall control of workshop production elements, including fluid equipment ledger (model, parameters, maintenance cycle), personnel skills and shifts, material inventory and circulation, tooling and fixture life, etc., to ensure that equipment, materials and personnel are configured as needed, and to avoid problems such as “work stoppage due to material shortage” and “operation of equipment with defects” in advance.

3.Production Execution and Process Control : Real-time tracking of fluid equipment operation progress, supporting operator reporting and input (completed quantity, qualified quantity, working hours), displaying standard operating procedures (SOPs) through workstation terminals, and implementing process error prevention—if equipment parameter settings are abnormal or material code scanning is incorrect, the system will automatically alarm and prohibit operation, while tracking the flow of work-in-process through barcode/RFID technology to achieve full-process traceability.

4.Quality Management : It runs through the entire production process, presets standards for incoming material inspection, process inspection, and finished product inspection, automatically collects operating parameters and inspection data of fluid equipment, analyzes data fluctuation trends through statistical process control (SPC), provides early warning of quality risks, initiates closed-loop handling processes (rework, scrap, and acceptance with concessions) for non-conforming products, and accurately traces the root cause of the problem.

5.Equipment Management and Maintenance : Establish a full lifecycle ledger for fluid equipment, develop preventative maintenance plans (such as regular cleaning and precision calibration), monitor equipment operating status in real time (running/standby/fault/maintenance), record fault phenomena and repair processes, automatically calculate overall equipment efficiency (OEE), and optimize maintenance strategies through data analysis to reduce unplanned downtime.

6.Data Acquisition and Monitoring : As the core carrier of information interaction, it collects real-time data from fluid equipment (dispensing speed, pressure, temperature, glue volume, number of operations, etc.) through various methods, integrates them into a production data hub, and provides data support for monitoring, analysis, and optimization.

(II) Typical interaction process between MES and fluid equipment

To more clearly present the collaborative process between the equipment and MES, the interaction logic of single-piece dispensing is broken down into 7 core steps, clarifying the triggering action, data transmission content, two-way feedback rules, and exception handling mechanism for each step.

step | Phase Name | Triggering subject | Device/IPC Actions and Reporting Data | MES System Actions and Return Data | Core objective |

1 | Device online and status confirmation | Dispensing machine / IPC | 1. Equipment startup 2. Report to MES: ▪ Device online status ▪ Current mode (Auto/Manual) ▪ Production Readiness Status (Whether Production is Available) | 1. Receive device status information. 2. Return: Whether to allow the device to participate in production. | Confirm device availability and establish a communication link between the device and the MES. |

2 | Operator login and permission verification | Operator | 1. Scan the QR code/login to your account on the device/IPC. 2. IPC sends a request to MES: ▪ Personnel legitimacy verification ▪ Workstation permission matching | 1. Verification personnel information and permissions 2. return: ▪ Allow/Deny Login ▪ Role Information (Operator/Process Engineer/Maintenance) | Ensure the operating entity is compliant and prevent unauthorized personnel from operating the system. |

3 | Work orders are linked to products. | Operator | 1. Scan the work order number + product serial number / barcode 2. IPC sends a query to MES: ▪ Work order validity ▪ Product process matching degree ▪ Is the product being produced repeatedly? | 1. Verify work orders and product data 2. return: ▪ OK → Allow dispensing to begin ▪ NG → Prevents device from starting | By linking production tasks to specific products, errors and duplicate production can be prevented. |

4 | Process parameters issued | MES system | 1. Issued to IPCs/devices: ▪ Dispensing Formulation ID ▪ Key process parameters (pressure, time, adhesive volume, etc.) ▪ Allowable fluctuation range of parameters | 1. The device receives and verifies parameters. 2. Feedback to MES: ▪ Parameter reception successful/failed ▪ Actual effective process parameters | Ensure that the equipment follows standardized processes and that parameters are traceable. |

5 | Dispensing execution and real-time monitoring | Dispensing machine/ PLC | 1. Perform single-piece dispensing action 2. PLC/IPC collects and uploads data in real time: ▪ Process parameters (pressure, time, adhesive volume, location) Report any critical anomalies (glue breakage, overpressure, positional misalignment) immediately. | 1. Receive process data in real time and monitor production status. 2. When an anomaly is triggered, a warning message will be pushed to relevant personnel. | Real-time monitoring of production quality and timely response to process anomalies |

6 | Dispensing results feedback | IPC | 1. After dispensing is complete, report to MES: ▪ Dispensing results (OK/NG) ▪ Actual process parameters ▪ Adhesive batch number ▪ Production timestamp, device number | 1. Record production history and associate product serial numbers. 2. Based on the results: ▪ OK → Allow clearance to the next process ▪ NG → Mark the product status and trigger the isolation process. | Achieve full traceability of production data and determine product circulation permissions. |

7 | Exception and Interception Mechanism | MES system/ device | 1. Triggering conditions: ▪ Dispensing result is NG ▪ Process parameters exceeded limits ▪ Glue batch expired/incompatible | 1. MES executes the interception action: ▪ Lock the serial number of the currently non-compliant product. ▪ Lock down the equipment and prohibit further production if necessary. ▪ Push an exception handling work order, requiring process/quality personnel to intervene. | Intercept defective products from circulation to avoid batch quality problems. |

Summary of core interaction features:

Two-way data closed loop: Each operation includes two-way interaction of “request-response” or “reporting-processing” to ensure that the device and MES status are synchronized.

End-to-end traceability: From equipment, personnel, work orders, parameters to results, all data is bound to the product serial number, enabling full lifecycle traceability of a single product.

Anomaly prevention interception: Set up multi-layered checks in work order binding, parameter issuance, process monitoring and other links, and trigger interception immediately when an anomaly occurs to reduce quality risks.

II . System Integration Architecture of MES with Fluid Equipment such as Dispensing Machines

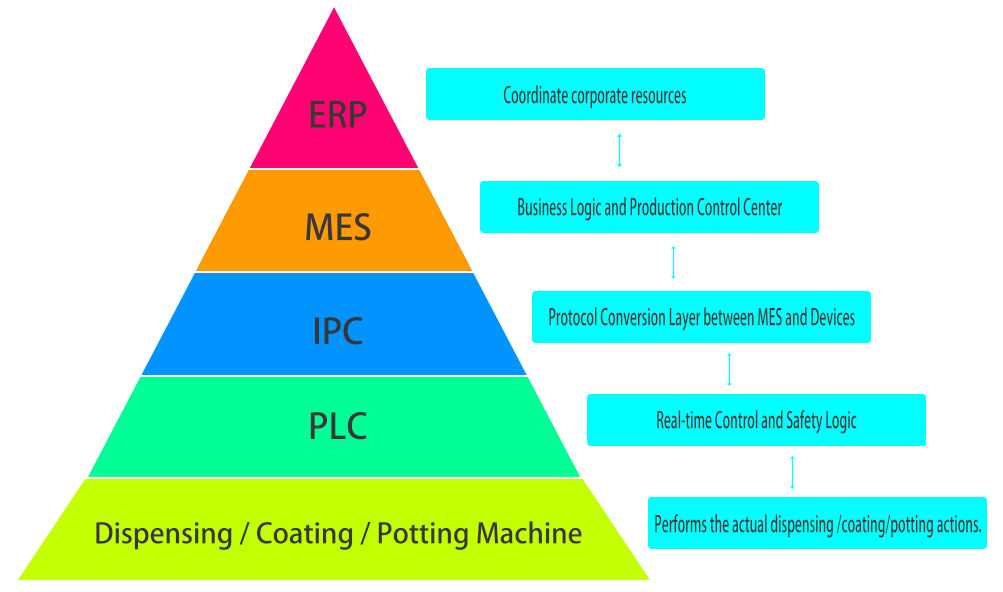

1. Typical system hierarchy

2. Common communication methods

hierarchy | Communication methods |

MES ↔ IPC | REST API / Web API / Socket |

IPC ↔ PLC | OPC UA / TCP/IP / Profinet |

PLC ↔ Dispensing Machine | I/O / Fieldbus / Dedicated Protocol |

The core of integrating MES with fluid equipment is achieving “two-way data communication”—MES sends operation instructions and parameters to the equipment, and the equipment feeds back its operating status and operation data to MES. Note that MES does not directly control the dispensing action, but manages it through a “command + status” approach.

3. Common data exchange formats

Data exchange formats are an important means of information transmission between MES systems and fluid equipment , and typically support the following common data exchange formats:

1.JSON format:A lightweight data exchange format that is easy to parse and generate.

2.XML format:It supports complex data structures and is suitable for a variety of application scenarios.

3.CSV format:Suitable for simple data recording, easy to import and export.

III . Key Design Principles for Integrating MES with Fluid Equipment

1. Clear responsibilities

MES manages “rules and results” . Equipment management “action and real-time control” , Avoid MES directly controlling motion or valve action.

2. Parameters must be “traceable”.

All parameters issued and actually used must have a version , source , and time ; this is a core requirement of quality systems (such as IATF 16949).

3. Clearly defined exception priorities

It needs to be able to distinguish between process anomalies , equipment anomalies , and human error anomalies , and define different MES response strategies.

4. Supports offline operation and complement mechanism

issues such as network anomalies and temporary unavailability of the MES may occur on-site. The system needs to support functions such as local caching , data retransmission , and prevention of data loss .

Ⅳ.Key Points and Implementation Suggestions for Integration and Interaction

Deep integration of MES with fluid equipment is not a simple matter of “software and hardware docking.” It requires comprehensive planning that takes into account production needs, equipment characteristics, and industry standards in order to maximize its value.

1.Unify data standards : In advance, sort out the data sources and data formats of fluid equipment, establish a standardized data dictionary, ensure that the data interaction between MES and equipment is unambiguous, and avoid integration obstacles caused by inconsistent data formats.

2.Adapt to equipment characteristics : Select the appropriate integration method based on the precision, interface type, and protocol support capabilities of the fluid equipment. Older equipment can achieve protocol conversion through middleware, while high-end equipment should prioritize the integration of standard protocols to balance integration costs and effectiveness.

3.Strengthen security protection : The workshop network needs to be divided into production control area and office area, and security measures such as firewalls and data encryption should be set up to prevent the interaction data between the MES system and equipment from being tampered with or leaked, and to ensure the stability of the production process.

4.Phased Implementation and Iteration : It is recommended to adopt a “pilot first, then gradually expand” strategy. First, select 1-2 core fluid devices to complete integration testing, verify the interaction logic and application effect, and then expand to all devices in the workshop to reduce the risk of implementation.

Ⅴ.Conclusion

In fluid application scenarios such as dispensing machines, coating machines, and potting machines, MES (Manufacturing Execution System) is not a “redundant management system,” but rather a core hub for ensuring quality, enabling traceability, standardizing processes, and enhancing the value of automation . A mature MES + dispensing machine integration solution should : not interfere with real-time equipment control , strictly control processes and data, and completely record every fluid application behavior . Only in this way can the value of automated equipment be truly transformed into replicable, traceable, and sustainably optimized production capabilities. Furthermore, with the development of Industrial Internet of Things (IIoT) and artificial intelligence technologies, the interaction between MES and fluid equipment will become increasingly intelligent in the future, enabling advanced functions such as predictive maintenance and adaptive process adjustments, injecting new momentum into the precision manufacturing industry.