Key Applications of Potting Machines in Precision Sensor and Capacitor Manufacturing?

Automated potting machine achieve uniform dispensing in the manufacture of precision sensors and capacitors, representing a complex system engineering project that integrates precision mechanics, fluid control, and intelligent processes. Its core lies in precisely controlling the spatial distribution, filling process, and curing behavior of the adhesive to ensure that the final adhesive layer is free of bubbles, has no missing adhesive, is of consistent thickness, and exhibits uniform stress.

Ι.Applications of automated potting machinein the manufacturing of precision sensors and capacitors are mainly reflected in the following aspects:

1.Protection and Sealing

● Moisture and Dust Protection: Precision sensors (such as pressure and humidity sensors) and capacitors are often exposed to harsh environments. Dispensing machines precisely fill epoxy resin, silicone, and other adhesives to form a sealing layer, preventing the intrusion of moisture, dust, and chemical corrosives.

● Protection Against Mechanical Shock and Vibration: After curing, the adhesive can buffer external impacts, protecting internal microcircuits and sensitive components, especially suitable for automotive and aerospace sensors.

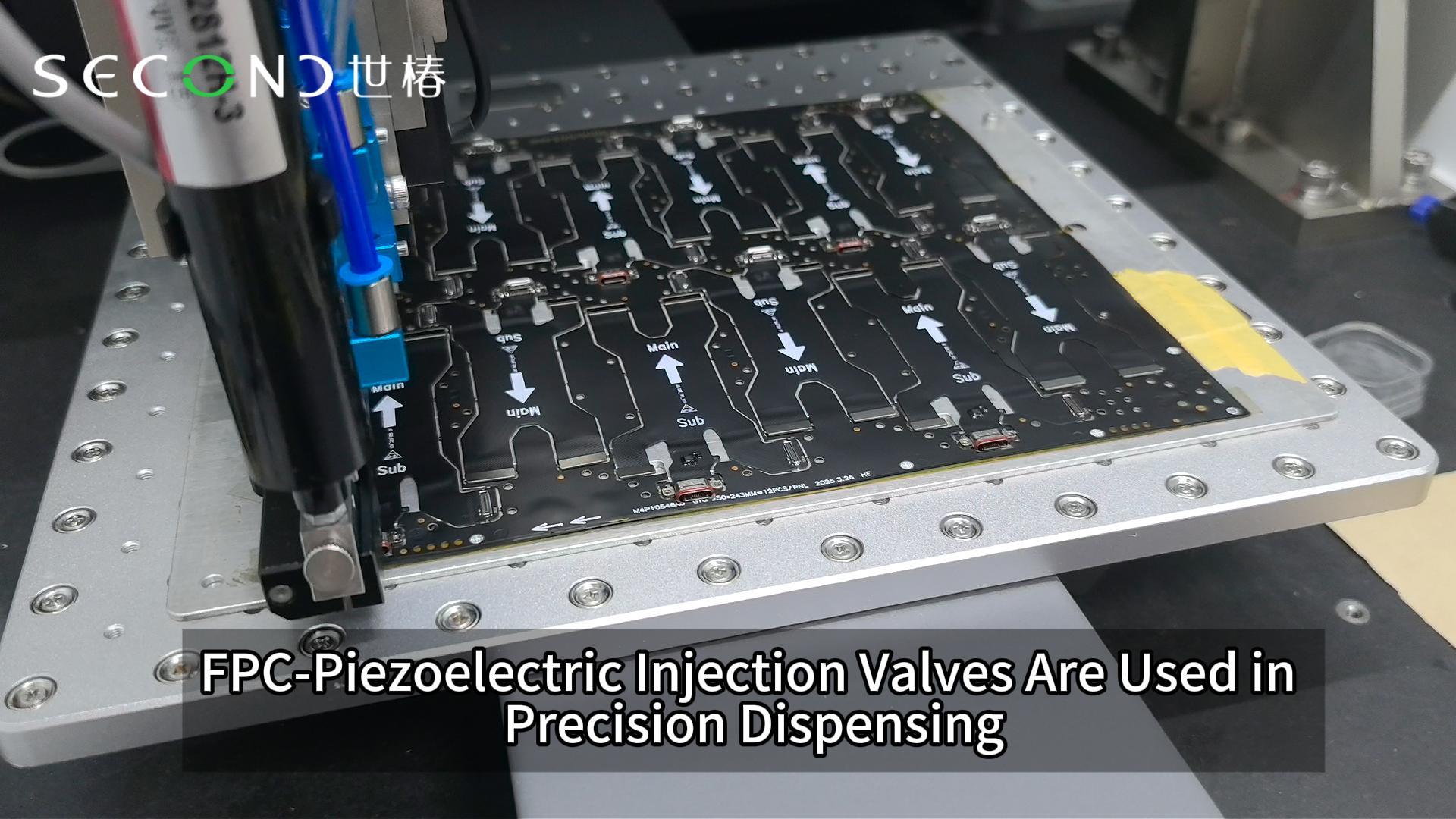

Fully Automatic 3-Axis Potting Machine SEC-S3030B & SEC-S3030C

The work of the glue potting machine mainly depends on air pressure control. Through the air pressure device, the glue is pressed out by pressure, and the size of the glue is controlled by the pump body. At the same time, the robotic arm is responsible for controlling the moving position of the glue discharge to achieve fully automated operation. This automated operation not only solves the problem of low labor efficiency, but also greatly improves the quality of production.

2.Insulation and Electrical Performance Optimization

● High Insulation Encapsulation: Prevents short circuits between capacitor electrodes or interference with sensor signals. The dielectric properties of the adhesive can improve the stability of high-frequency capacitors.

● Reduced Parasitic Capacitance Influence: By controlling the thickness and uniformity of the adhesive layer, sensor measurement errors are reduced.

3.Thermal Management

● Heat Dissipation and Temperature Uniformity: Some adhesives contain thermally conductive fillers (such as boron nitride and aluminum oxide) to help dissipate heat from power capacitors or high-power sensors, avoiding localized overheating failure.

● Temperature cycling protection: The colloid adapts to temperature difference expansion and contraction, reducing thermal stress damage to solder joints or microstructures.

4.Structural Reinforcement and Integration

Fixed Internal Components: Prevents displacement of capacitor electrodes or sensor diaphragms due to vibration, improving mechanical strength.

Modular Packaging: Enables integrated potting of multiple chips/components, reducing size and suitable for miniaturized MEMS sensors and surface-mount capacitor modules.

5.Process Precision and Consistency

Vacuum Potting Eliminates Air Bubbles: Air bubbles can cause sensor measurement drift or partial discharge in capacitors. The potting machine integrates vacuum degassing to ensure a void-free adhesive layer.

Precise Micro-volume Control: High-precision metering pumps and motion control systems enable micro-volume dispensing, suitable for encapsulating miniature sensors or sealing capacitor pins.

Automation and Yield Improvement: Enables fully automated positioning, potting, and curing processes in conjunction with production lines, reducing human error and improving production efficiency and consistency.

Ⅱ.The following are the key technologies and methods for achieving uniform glue application:

1.Adhesive Pretreatment and Temperature Control

* Adhesive Pretreatment: Before use, two-component adhesives (such as epoxy resin and silicone) are stored in a constant temperature chamber to ensure viscosity stability.

* Dynamic Viscosity Control: The dispensing machine integrates heating functions (such as heating the feed tube and mixing tank) to control the adhesive temperature at the optimal process point (typically 25℃~60℃), ensuring consistent adhesive flow and facilitating the filling of minute gaps.

* Vacuum Degassing: The adhesive undergoes degassing in a vacuum chamber after mixing or before dispensing to eliminate internal air bubbles and prevent voids after filling.

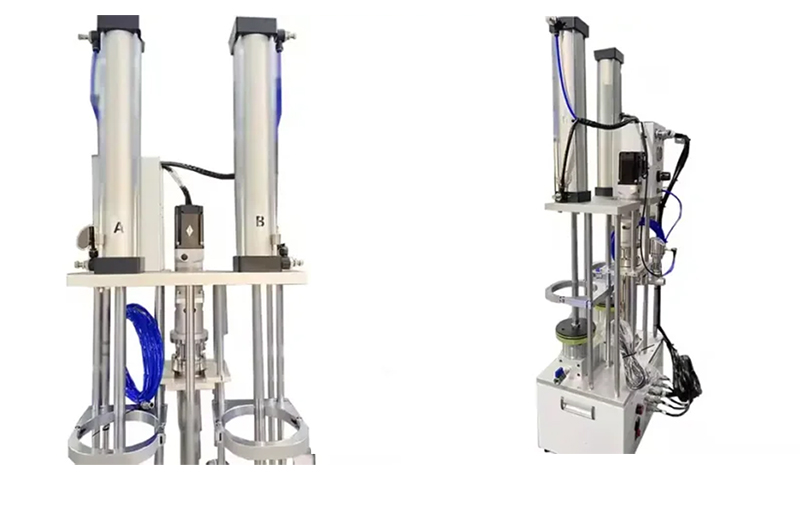

2.Precision Metering and Mixing Potting System

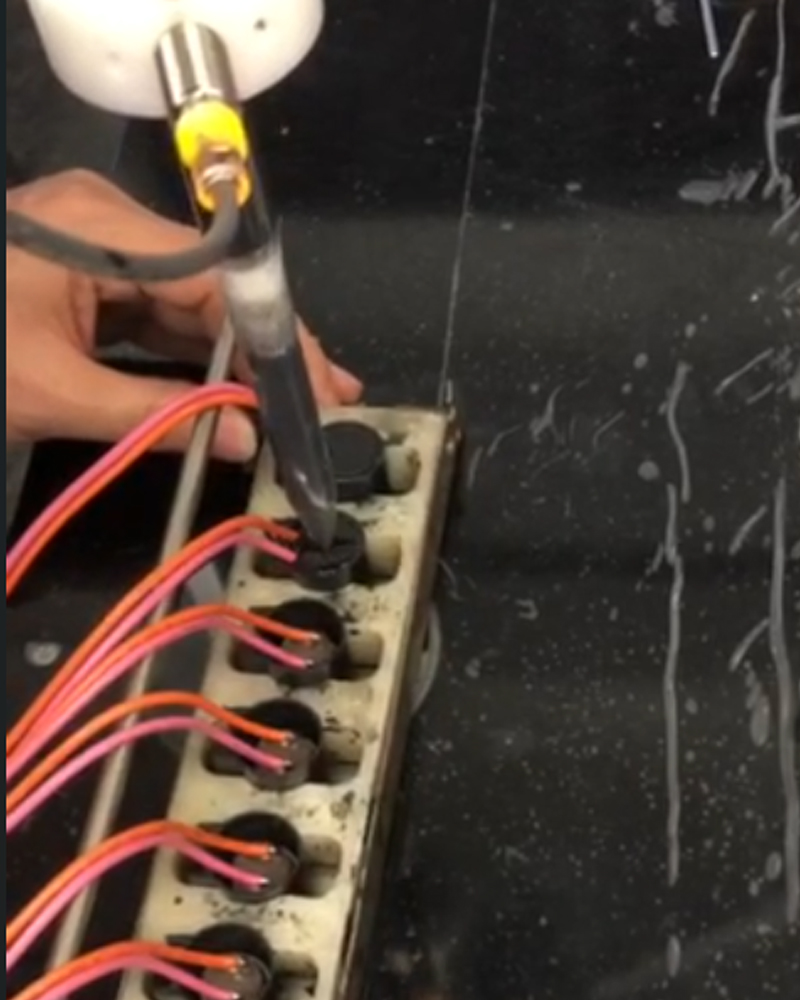

* High-Precision Metering Pump: Utilizing gear pumps, screw pumps, or piston pumps in conjunction with a servo motor, a volumetric metering accuracy of ±0.5%~±1% is achieved, ensuring a constant A/B component ratio.

Double barrel screw pump glue supply

* Dynamic Mixing Technology:

* Static Mixing Tube: The adhesive is continuously divided and recombined through internal spiral blades, achieving uniform mixing without cleaning residue.

Dynamic Agitator: For high-viscosity or filler-containing adhesives, adjustable-speed mechanical agitation ensures uniform distribution of fillers (such as silica and ceramic powder) and prevents sedimentation.

3.Precise Path and Flow Control

Multi-Axis Motion Platform: The dispensing head is mounted on an XYZ three-axis or multi-joint robot. Programmable paths ensure adhesive coverage of every corner. For complex cavities (such as sensor housings), three-dimensional spiral filling or multi-segment linear scanning paths are used.

Flow-Speed Matching: The dispensing machine automatically calculates the matching relationship between adhesive volume (Q) and moving speed (V) based on the preset adhesive strip width and height (Q = V × cross-sectional area).

Automatic deceleration in corners or narrow areas avoids accumulation; uniform speed movement in open areas ensures a smooth adhesive layer.

Needle Positioning and Height Tracking: Laser or contact height sensors monitor the workpiece surface in real time, maintaining a constant distance between the needle and the dispensing surface (typically 1~5mm) to prevent uneven adhesive diffusion due to height changes.

4.Cavity Filling and Venting Design

“Inside-out” or “Low-to-high” filling strategy: For deep-cavity capacitors or sensor housings, glue is injected starting from the center of the bottom of the cavity. The glue rises along the walls, naturally expelling air through the top vent.

Tilted potting and centrifugal assistance: For extremely small MEMS sensor cavities, the workpiece can be tilted at a certain angle during glue injection, or briefly centrifuged after injection to use gravity/centrifugal force to expel air bubbles.

Mold and runner design: In mass production, molds are designed with guide channels and vents to guide glue flow and expel air.

5.Process Monitoring and Closed-Loop Feedback

Visual inspection system: An industrial camera takes a picture immediately after glue injection. AI algorithms analyze the glue coverage area, height, and presence of defects. Defective products are automatically marked for rework.

Pressure and flow sensors: Real-time monitoring of glue dispensing pressure. If the pressure abnormally increases (potentially causing blockage) or decreases (potentially causing insufficient glue), the system automatically alarms or adjusts parameters.

Online Viscosity Monitoring: Some high-end equipment integrates online viscometers, allowing for fine-tuning of mixing ratios or temperature based on viscosity.

6.Curing Process Control

Gradient Temperature Curing: After dispensing, the adhesive enters a temperature-controlled curing oven. The temperature rises slowly according to a preset curve, ensuring simultaneous curing of the internal and external components of the adhesive, reducing internal stress or cracks caused by uneven shrinkage.

UV/Heat Dual Curing: For photosensitive adhesives, UV pre-curing is used for shaping, followed by heat curing to enhance performance and prevent the adhesive from flowing and deforming before complete curing.

7.Special Processes for Complex Structures

Underfill: Used for chip-level sensors or capacitors, the adhesive automatically seeps into the bottom of the chip through capillary action. The dispensing machine needs to precisely control the dispensing volume and position to achieve uniform filling.

Layered Dispensing: For high aspect ratio structures, dispensing is done in two stages: first, the bottom layer is dispensed, and after semi-curing, the top layer is dispensed, avoiding voids caused by adhesive shrinkage during a single filling.

Vacuum pressure potting: The workpiece is placed in a sealed cavity, vacuum is drawn and glue is injected, and then pressure (0.2~0.5MPa) is applied to drive the glue to penetrate the tiny pores, achieving bubble-free filling.

Summary:

Core Technology The essence of a glue potting machine achieving uniform dispensing lies in transforming the variable material of adhesive into a controllable “manufacturing tool.” Through a three-pronged approach—hardware precision (pumps, valves, motion axes), software intelligence (path planning, parameter adaptation), and process knowledge (adhesive properties, cavity design)—it ensures that the adhesive behaves as expected at the microscale, thereby providing reliable and consistent protection and enhancement for precision sensors and capacitors.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.

[contact-form-7 id=”5″ title=”Contact form 1″]