What are application examples of Lubricating Grease Dispensing in the automotive bearings and gears?

Lubricating Grease dispensing technology is widely and critically used in the automotive industry for bearings and gears. It enables precise, efficient, and clean grease application, making it an indispensable part of modern automated automotive production lines.

Below are several specific application examples and detailed explanations:

Ι.Bearing Application Cases Various bearings are widely used in automobiles.

The amount, location, and consistency of grease application directly affect the bearing’s lifespan, noise level, and performance.

1.Wheel Hub Bearing Units

● Application Description: Modern automobiles commonly use integrated wheel hub bearing units. During assembly, a specific amount of grease needs to be precisely injected into the bearing’s raceways and sealing cavities.

● Advantages of Dispensing Technology:

Precise Quantification: Glue Dispensing equipment can precisely control the amount of grease dispensed each time (usually measured in grams or milliliters), ensuring consistent lubrication for each bearing and avoiding problems with too much (leading to increased resistance and overheating) or too little (leading to wear).

Automated Integration: Dispensing robots or automated dispensing stations can be easily integrated into wheel hub assembly lines, enabling high-speed, rhythmic production.

Clean and Environmentally Friendly: Compared to manual application, the dispensing process is leak-free and splash-free, keeping the workpiece and working environment clean.

Commonly Used Greases: High-performance lithium-based greases and polyurea-based greases possess excellent mechanical stability, rust prevention, and wide temperature range performance.

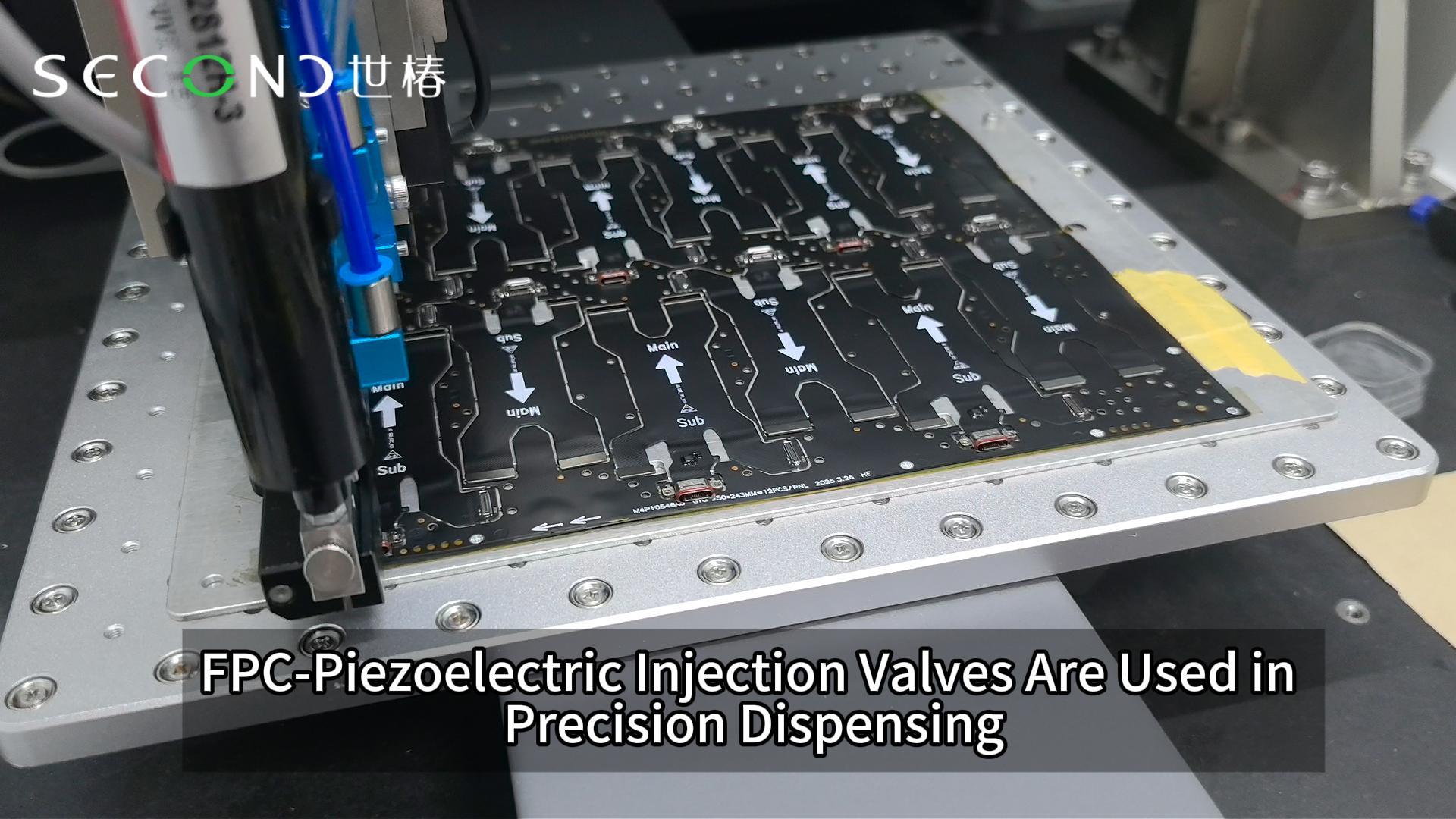

Automatic In-line PCB Glue Dispensing Machine SEC-DH400L

Second Intelligent In-line Glue Dispensing Machine SEC-DH400L adopts an integrated mineral casting design, with ultra-high precision and super stability, powerful expansion capabilities, and can realize ion cleaning, dispensing, detection, UV exposure and other functions;

Adopting a gantry structure, it can bear large loads, stable structure, and a powerful CCD visual positioning system, which can meet the requirements of Mark point positioning, edge positioning, and 3D scanning positioning; strong scalability, and can expand AOI detection 3D detection, UV exposure curing and other functions;

Strong platform compatibility, contact and non-contact dispensing, single-head and multi-head synchronous dispensing, automatic compensation and adjustment of double-head spacing, five-axis dispensing function based on needle A/R displacement, etc.

2. Generator and Starter Bearings

● Application Description: These are critical electrical components in the engine compartment, operating at high speeds and experiencing significant temperature variations. Their internal deep groove ball bearings require long-term, reliable lubrication.

● Advantages of Dispensing Technology:

Deep Dispensing: The dispensing needle can reach inside the bearing, ensuring that grease is accurately delivered to the contact area between the balls and raceways—something difficult to achieve manually.

High Consistency: Ensures that the amount of grease in each motor bearing is exactly the same under mass production, thus guaranteeing consistent product lifespan.

Common Greases: High-temperature resistant synthetic oil greases (such as PAO and ester-based oils) offer excellent oxidation stability and long service life.

3. Air Conditioning Compressor Clutch Bearings

● Application Description: This bearing operates under harsh conditions of high temperature, high humidity, and frequent start-stop cycles.

● Advantages of Dispensing Technology:

Micro-dosage Control: Space is limited in this area, requiring only a small amount of grease. Dispensing technology enables precise, micro-level dispensing.

Reliability assurance: Precise lubrication is one of the key factors in avoiding premature clutch failure.

smt automatic dispensing machine SEC-DH600L

Ⅱ.Gear Application Cases

Gear transmissions in automobiles also rely on precise lubrication.

1. Window Regulator Gears

● Application Description: Plastic or metal gears, driven by an electric motor, require lubrication to reduce wear and noise.

● Advantages of Dispensing Technology:

Targeted Application: Lubricant can be applied in targeted, crisscross, or spiral patterns on the meshing surfaces of the gears, ensuring that critical friction areas are covered.

Preventing Contamination: Precisely controlling the application path prevents grease from contaminating surrounding plastic parts or switch contacts.

● Commonly Used Greases: Low-noise, plastic-compatible white grease.

2. Seat Adjuster Worm Gear

● Application Description: Seat adjusters typically use worm gear mechanisms, a sliding friction pair that requires high lubrication.

● Advantages of Dispensing Technology:

Filling the Meshing Area: Automatic glue dispensing system ensures that a dense grease is fully filled on the meshing contact surface of the worm and worm wheel, forming an effective lubricating film.

Process Controllable: The dispensing trajectory can be programmed to perfectly match the helical shape of the worm gear, achieving uniform coverage.

Commonly Used Greases: High-adhesion, extreme-pressure greases, such as those containing MoS2 (molybdenum disulfide).

3. Windshield Wiper Motor Gearbox

● Application Description: Windshield wiper gearboxes operate in environments with vibration, temperature, and humidity variations.

● Advantages of Grease Dispensing Technology:

Integrated Sealing and Lubrication: Applying a specific amount of grease not only lubricates the gears but also helps to seal them, preventing moisture and dust from entering.

Automated Production: Grease dispensing is automatically completed by a robot before the gearbox housing is closed, resulting in high efficiency.

● Commonly Used Greases: Wide-temperature, waterproof, long-life complex calcium sulfonate-based or lithium-based greases.

Conclusion: Grease dispensing technology has evolved from a simple “filling” process into a key technology ensuring reliability, consistency, and high efficiency in precision automotive manufacturing. Its successful application in bearings and gears directly improves the lifespan and performance of core automotive components while reducing overall production costs, serving as a typical microcosm of intelligent and automated manufacturing in the automotive industry.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.

[contact-form-7 id=”5″ title=”Contact form 1″]