How can the yield rate of mobile phone frame structures be improved to over 99.9% by optimizing the dispensing solution?

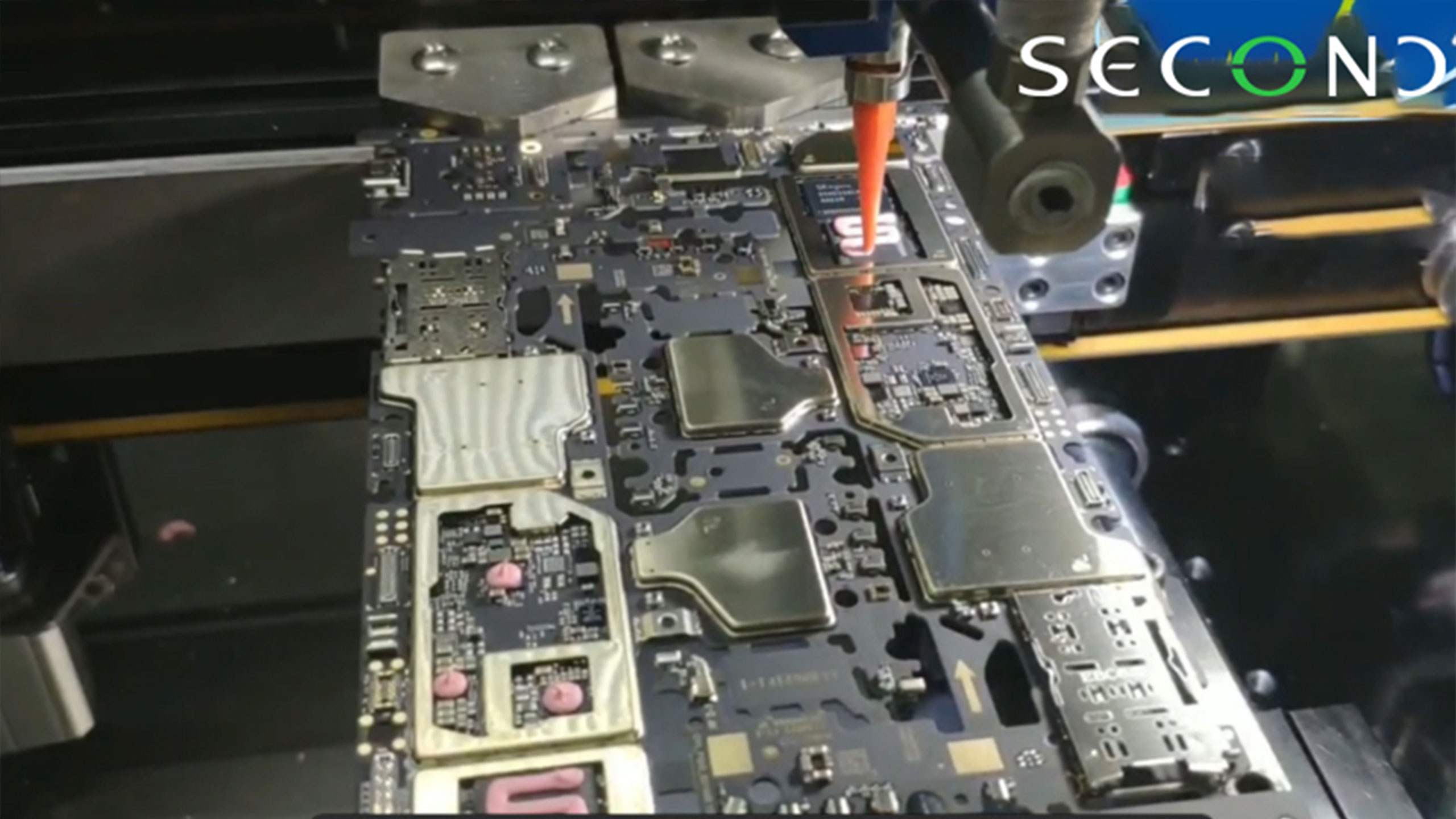

In the field of smartphone manufacturing, every detail is related to the final quality of the product and user experience. Among them, the sealing and stability of the mobile phone frame are one of the key factors, and the dispensing process in its production process is particularly important. Today, we will delve into an industry hot topic – how to achieve a leap-forward improvement in the yield rate of mobile phone frame structures through refined and intelligent dispensing solution optimization, aiming for a high standard of more than 99.9%.

Core Objective: Achieving a “Zero-Defect” Dispensing Process

A 99.9% yield rate signifies a “zero-tolerance” approach to defects. Our strategy focuses on two key areas: “preventing defects from occurring” and “timely detection and removal of defects.”

1.Root Cause Analysis: Identifying Existing Defects

Before optimization, it is essential to conduct a precise analysis of all defect types and their root causes under the current yield rate. Common dispensing defects include:

a.Insufficient adhesive volume: Leading to seal/bond failure and waterproofing failure.

b.Excessive adhesive volume (adhesive overflow): Contaminating internal components, cameras, speaker grilles, buttons, etc., affecting functionality and appearance.

c.Adhesive breakage: Gaps in the seal line directly causing leaks.

d.Bubbles: Air bubbles in the adhesive forming holes after curing, affecting seal strength and consistency.

e.Stringing: Fine adhesive threads form when the dispensing head is lifted, which may fall off and cause short circuits.

f.Poor curing: Insufficient strength or stickiness after curing.

Methods: Use SPC (Statistical Process Control) tools to analyze production data, perform teardown analysis on defective products, and observe defect morphology using equipment such as microscopes and optical profilometers.

2.Optimization Solution: Comprehensive Upgrades Across Six Dimensions

a.Method – Process and Method Optimization

This is the core component.

● High-Precision Dispensing Valve and Pressure Control:

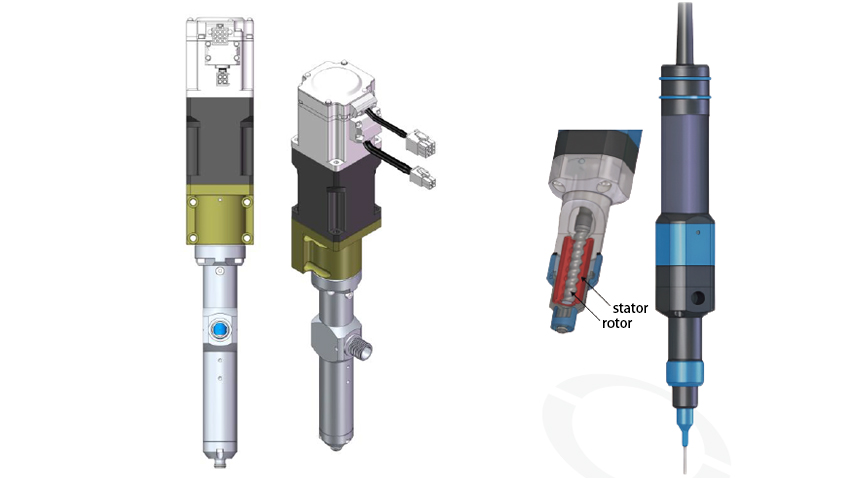

Abandoning traditional timed jet valves, piezoelectric jet valves or screw valves are adopted.

Piezoelectric Dispensing Valve: Suitable for low-viscosity glues, with high frequency (hundreds of Hz), precise dispensing volume control in nanoliters, virtually eliminating stringing, making them ideal for the delicate paths of mobile phone frames.

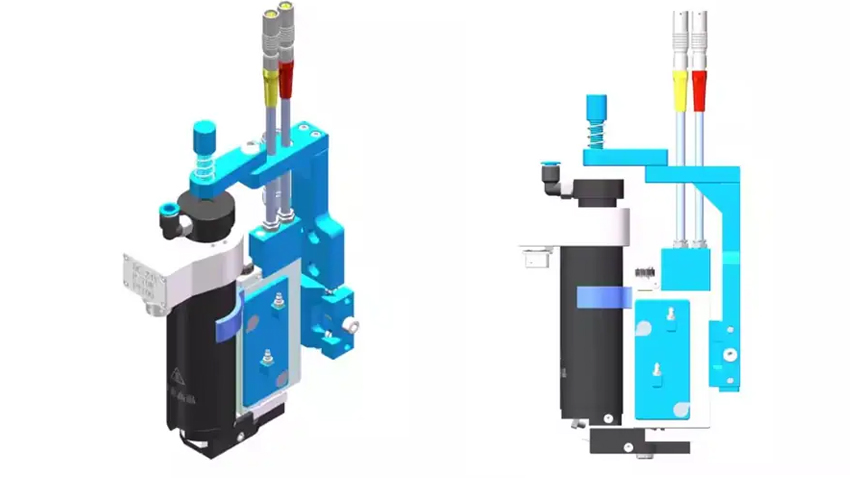

Piezoelectric Dispensing Valve

Screw valves: Suitable for high-viscosity, filler-containing glues. Extruded through a rotating screw, they offer precise control and high repeatability (up to ±0.5%).

Screw valves

Real-Time Pressure Control: A closed-loop pressure controller monitors and adjusts the glue barrel pressure in real time, compensating for pressure loss caused by glue volume reduction and viscosity changes, ensuring highly consistent glue delivery.

● Path and Parameter Optimization:

3D non-contact dispensing: Given the curved and varying heights of mobile phone frames, a laser rangefinder is used to track the Z-axis height in real time to ensure a constant distance between the dispensing head and the workpiece, avoiding inconsistent glue line width due to height variations. Intelligent Path Planning: Compensate for speed and glue output at the path’s starting point, end point, and corners. For example, speed can be reduced or glue output frequency increased at corners to prevent uneven glue delivery due to centrifugal force.

Multi-Segment Parameter Setting: Divide a single glue path into multiple segments, allowing you to set different dispensing parameters for different areas, such as straight lines, corners, and interfaces.

Glue Management:

Constant Temperature Storage and Transportation: Glue viscosity is extremely sensitive to temperature. Temperature-controlled glue storage bins, delivery hoses, and dispensing valves must be used to maintain a stable glue temperature within a ±0.5°C range.

Vacuum Degassing: Centrifuge or vacuum degassing is performed before the glue is loaded into the pressure drum to eliminate bubbles at the source.

Automatic Glue Mixing and Purge: For two-component glue, use a static mixer and set an initial purge program to ensure a uniform and stable mix before dispensing on the product.

3.Machines – Equipment and Automation

High-Precision Motion Platform: Utilizes a high-rigidity, high-precision linear motor or servo motor platform with repeatable positioning accuracy better than ±5µm to ensure path repeatability.

Machine Vision Integration:

● Pre-positioning: Before dispensing, a vision system is used to precisely locate the phone frame, compensating for positioning tolerances in incoming materials or fixtures to ensure the dispensing path is consistently correct.

● In-Process Monitoring: An integrated online visual inspection system uses a high-speed camera to inspect the glue path for continuity, width, and position defects during or immediately after dispensing. Immediately detect defects and mark the product.

● Post-Process Inspection: Before curing, a 3D line laser scanner performs a 100% inspection of the glue profile, measuring the height, width, and cross-sectional area of the glue line to ensure it remains within strict tolerances. This is a critical line of defense for achieving a 99.9% yield rate.

● Equipment Maintenance: Establish a strict preventive maintenance plan and regularly replace consumable parts such as needles, seals, and mixing tubes. 3. Materials – Material Consistency Control

Supplier Management: Establish strict quality agreements with adhesive suppliers, requiring them to provide inspection reports for key parameters such as viscosity, specific gravity, and curing properties for each batch of material.

Incoming Material Inspection: The laboratory conducts random inspections on each batch of incoming material to verify key parameters and ensure batch-to-batch consistency.

4.Environment – Environmental Control

Cleanroom: The dispensing area should be located in a dust-free room to prevent dust from settling on the adhesive path or in the adhesive.

Temperature and Humidity Control: Maintain the workshop temperature and humidity within a stable range (e.g., 23°C ± 2°C, 50% ± 10% RH) to minimize environmental impacts on adhesive performance and equipment stability.

5.Measurement – Measurement and Data Feedback

SPC Statistical Process Control: All inspection data (glue width, glue height, and visual inspection results) is uploaded to the MES system in real time. Control charts are used to monitor process stability. If a trend (e.g., a gradual decrease in glue width) is detected, the system will immediately issue an alert, prompting engineers to make adjustments before scrap is generated, enabling predictive maintenance. Full-Process Traceability: Each product is uniquely coded, and all dispensing parameters, equipment status, and test results are recorded. Any issues can be quickly traced back to the specific batch, workstation, and even time.

6.People – Personnel Training and Standardization

Standardized Operations: Develop highly detailed standardized operating instructions covering equipment operation, material change procedures, inspection checklists, and exception handling.

Professional Training: Operators and engineers must not only know how to perform tasks, but also understand why they are performed and be able to identify early signs of anomalies.

Summary: Key Points for Achieving a 99.9% Yield Rate

● Shift in Mindset: From “Post-Inspection” to “Pre-Prevention and In-Process Control.”

● Technological Investment: Utilizing cutting-edge technologies such as piezoelectric/screw valves, real-time pressure control, 3D vision positioning, and online/offline 3D inspection is essential.

● Data-Driven: SPC is the core brain for achieving ultra-high yields and process stability, making the production process transparent and predictable.

● Systematic Management: Optimizing and standardizing every aspect of the process: people, machines, materials, methods, environment, and testing.

Through this comprehensive approach, raising the yield rate of mobile phone frame dispensing to over 99.9% is a completely achievable and scientifically sound industrial goal. This requires upfront investment and meticulous execution, but the resulting quality improvements and cost savings (reduced rework and scrap) are enormous.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.