Which glue potting machine is the most suitable for PCB waterproof encapsulation?

Which type of glue potting machine is the most suitable for PCB waterproof encapsulation, which requires comprehensive consideration of a variety of factors, including the precision of the two component glue potting machine, efficiency, applicable glue type, process requirements, cost and so on.

In order to find the most suitable for PCB waterproof encapsulation glue potting machine, you need to understand the characteristics and scope of application of different types of glue potting machine, PCB waterproof encapsulation of the specific process requirements, as well as the type of glue applicable to the process and glue potting machine parameter settings.

The following are several types of glue potting machine suitable for PCB waterproof encapsulation and related features

1.Automatic Glue Dispensing Machine

Advantages

High Precision Control: Equipped with a precision mixing valve, it achieves glue volume control accuracy of ±2%, suitable for micron-level dispensing requirements. It can precisely cover circuit board components and solder joints, ensuring waterproof effects. Supports path programming, adapting to different circuit board sizes and complex trace structures, suitable for both small electronic devices and large industrial PCBs 2.

Strong Intelligence and Adaptability: Built-in temperature control modules (0–80°C) accommodate variations in glue viscosity, ensuring optimal fluidity and curing effects. Supports a wide range of dual-component glue ratios (e.g., 1:1 to 10:1 for epoxy resin, silicone, or polyurethane), meeting diverse waterproof encapsulation needs 2.

High Efficiency and Stability: Automated continuous operation with dispensing speeds of 10–500g/min, significantly improving production efficiency. Features automatic cleaning and anti-drip functions, reducing downtime and maintenance costs 2.

Flexible Processes: Optional glue dispensing valve (contact/non-contact) and vision positioning systems enable high-precision filling, sealing, or localized dispensing, adaptable to various PCB designs and waterproofing requirements 2.

Disadvantages: Higher equipment costs and a steeper learning curve for operators, requiring technical training and support.

Automatic dual two-component glue potting machine SEC-S3030-C

- The unique motion controller of Second Intelligent, combined with advanced algorithms and high-precision three-axis manipulator, can realize three-dimensional high-speed and accurate motion

- By accurately controlling the metering motor, the precise proportion of two-component glue, automatic mixing and automatic quantitative glue are achieved

It has vacuum feeding and vacuum degassing, and can be equipped with heating, stirring, automatic cleaning, pressure monitoring and other functions to cope with various complex glue environments

The operating system is stable, the operation interface is friendly, and the cost performance is high!

2. In–line Glue Dispensing Machine

Advantages

Full Automation: Seamlessly integrates into assembly lines for fully automated processes, from PCB conveying to gluing and curing. Ideal for large-scale production, as proven in applications like battery covers and bulb lights, ensuring consistent quality and throughput 45.

Precision Control: Advanced systems regulate glue volume, speed, and positioning accurately, minimizing human error and ensuring uniform waterproofing results.

Labor Savings: Eliminates manual operations, reducing labor costs and workload while improving product consistency.

Disadvantages: High initial investment, requires adequate space and optimized production line layout.

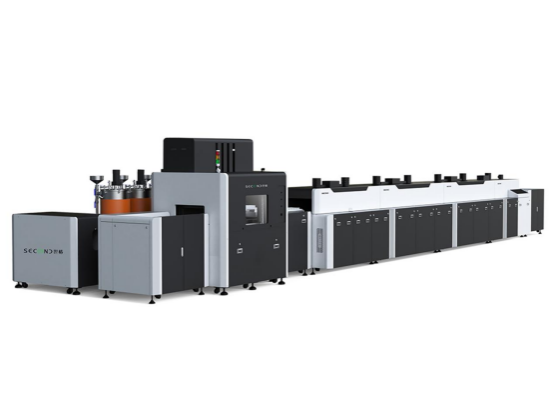

Automatic In-Line Vacuum Glue Potting Machines Production Line

3.Semi-Automatic Glue Dispensing Machine

Advantages

User-Friendly: Simpler operation than fully automatic machines, requiring minimal training. Automatically mixes glues in various ratios, meeting basic PCB waterproofing requirements 345.

Cost-Effective: Affordable for small to medium enterprises or low-volume production, balancing budget constraints with functionality.

Versatility: Adapts to different PCB sizes and models, suitable for businesses with diverse products but lower batch sizes.

Disadvantages: Lower efficiency due to manual assisted operations (e.g., PCB loading). Mixing precision and consistency may lag behind fully automatic machines.

Two-component semi-automatic glue potting machine SEC-S8700-E

SECOND Two-component semi-automatic glue potting machine SEC-S8700-E through the precise control of the metering motor by PLC, the two-component glue can be

accurately proportioned, automatically mixed, and automatically quantitatively discharged;

● With functions such as vacuum feeding, vacuum degassing, heating, stirring, and automatic cleaning, it can cope with various complex glue environments;

● Unique industrial design, elegant appearance, compact structure, stable operating system, friendly operating interface, and high cost performance;

● Simple operation, greatly saving manual proportioning and mixing time, improving efficiency, saving costs, and high cost performance;

● Optional 1.2-meter double-joint cantilever handheld glue pouring, flexible and easy to operate;

4. Simple Glue Dispensing Machine

Advantages

Simple Design: Comprises two material buckets and a pneumatic cylinder, dispensing glue via air pressure. Typically suits a 1:1 ratio for basic applications, ideal for small workshops or budget-limited scenarios 345.

Ease of Use: Intuitive operation and maintenance, requiring no specialized skills, suitable for quick setup and straightforward tasks.

Disadvantages: Limited functionality for complex PCBs, high-precision requirements, or special glue ratios. Mixing effectiveness and dispensing accuracy are inferior to advanced machines.

Selection Guidelines

When choosing a machine, consider factors such as PCB size/shape, production volume, glue properties, budget, and environmental constraints. For high-volume, precision-critical tasks, opt for automatic or inline machines. For low-volume or cost-sensitive scenarios, semi-automatic or simple machines may suffice.

This translation maintains the technical details and structure of the original Chinese article while adapting it for English readers. Let me know if further adjustments are needed!

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.