Second Intelligent DH Series and Plunger Press Pumps: The Perfect Duo in Industrial Automation

In today’s rapidly evolving industrial automation sector, companies are constantly raising the bar for production efficiency and product quality. To meet these demands, a plethora of advanced equipment and technologies have emerged. Among them, the combination of Second Intelligent’s DH series online dispensing machines and plunger press pumps offers an ideal solution for the precise dispensing of high-viscosity adhesives.

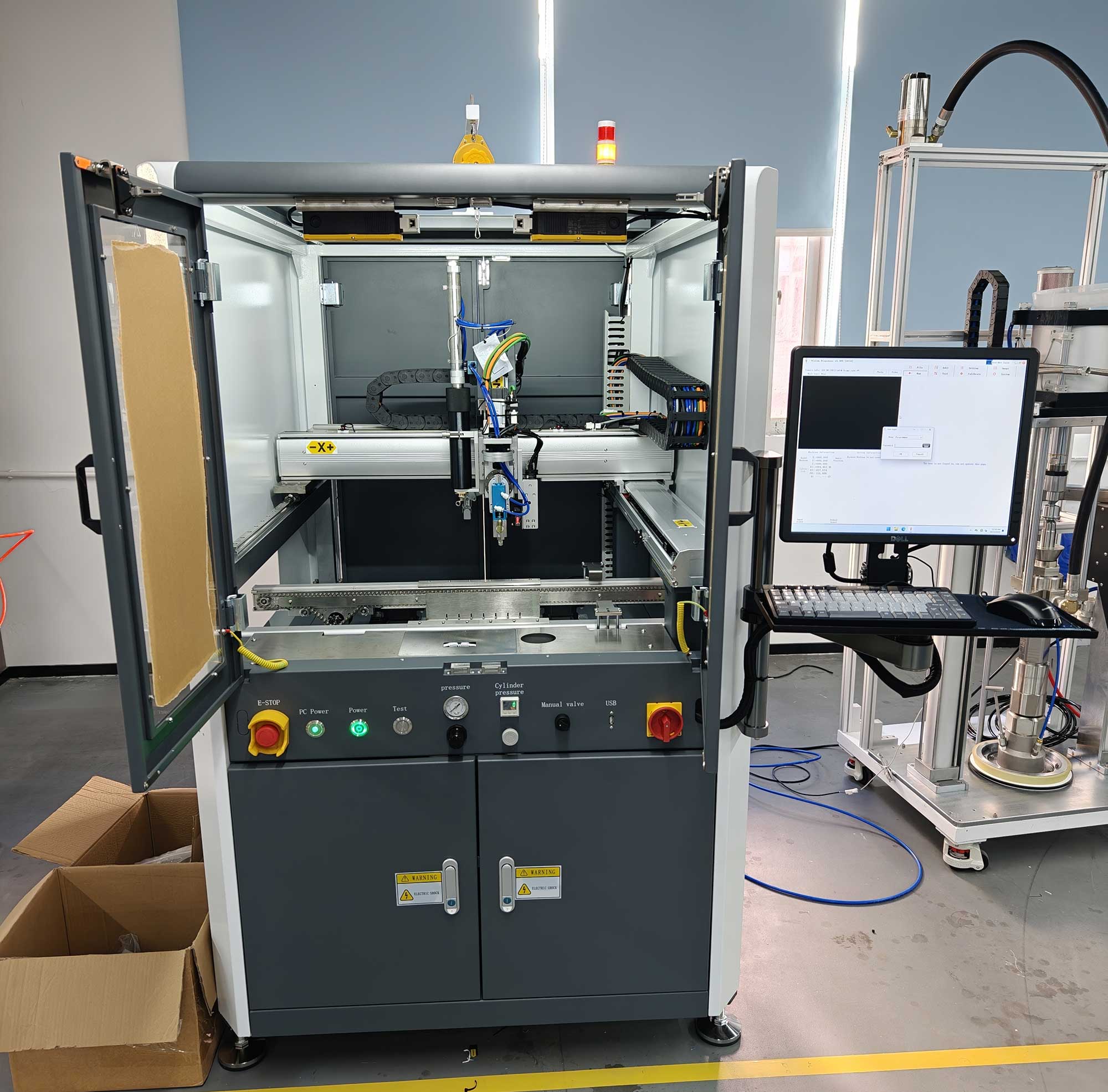

Second Intelligent’s DH series online dispensing machines are renowned for their exceptional performance and powerful features. These dispensers are built on an integrated mineral casting platform, ensuring extremely high precision and stability. The overhead gantry structure allows them to handle significant loads while maintaining structural integrity. Moreover, the DH series dispensers are equipped with a robust vision positioning system that can meet various positioning requirements, such as Mark point positioning, edge-grabbing positioning, and 3D scanning positioning.

The DH series dispensers come in several models to cater to different customer needs, including the SEC-DH400L, SEC-DH600L, and SEC-DH800L. These models vary in dispensing range, machine size, drive method, and maximum load capacity, but all share the characteristics of high precision and stability. For instance, the SEC-DH400L has a dispensing range of X400/Y400/Z100 millimeters, while the SEC-DH800L offers a range of X800/Y800/Z100 millimeters. These dispensers are also equipped with servo motors and either ball screw or linear motor modules (optional) to achieve rapid movement speeds and high acceleration.

SEC-DH600L

The plunger press pump is a core component in hydraulic control systems, particularly suitable for conveying high-viscosity adhesives with multiple fillers. This pump reliably transfers high-viscosity fluid materials from adhesive packaging to metering and dispensing systems. Second Intelligent’s plunger press pumps feature multiple functional characteristics that make them stand out in industrial applications.

(1)High-Speed Pneumatic Switching Technology

The plunger press pump employs an independently developed high-speed pneumatic switching technology with a switching time of less than 100 milliseconds, ensuring stable adhesive supply. This rapid switching not only enhances production efficiency but also reduces fluctuations in adhesive delivery, ensuring uniform and consistent dispensing.

(2)Anti-Icing Function

Under high-viscosity and high-flow working conditions, plunger press pumps are prone to icing, which can affect adhesive conveyance and dispensing quality. Second Intelligent’s plunger press pumps feature a progressive exhaust structure that effectively prevents icing, ensuring stable operation under various working conditions.

(3)Low Maintenance Costs

The plunger press pump has a long service life, capable of cycling 20 million times without the need for regular lubricant addition. Its modular design significantly reduces maintenance and replacement time, lowering maintenance costs. This design not only enhances equipment reliability but also minimizes downtime, improving production efficiency.

(4)Energy-Efficient and Environmentally Friendly

Compared to similar products, the plunger press pump consumes less air and produces lower noise levels (less than 75 decibels). This energy-efficient and environmentally friendly design not only reduces energy consumption but also improves the working environment, meeting modern industry’s environmental requirements.

(5)Multiple Options

The plunger press pump offers a variety of options, including cost-effective cylinders and high-performance pneumatic motors. These options can be selected based on different industrial application requirements, ensuring the equipment’s flexibility and adaptability.

(6)High Output Pressure and Large Displacement

The plunger press pump can provide high output pressure with a pressure ratio of 43:1. For example, based on the standard factory air pressure of 0.6Mpa, the pump can supply adhesive pressure up to 25.8Mpa. Additionally, the pump can convey 170cc of fluid per cycle, ensuring efficient adhesive delivery.

(7)Excellent Wear Resistance

The plunger rod of the plunger press pump is made of specially treated carbon steel or ceramic materials, and key structures feature embedded tungsten steel to withstand impact wear. The unique sealing structure design and the use of special sealing materials significantly extend the service life of the seals.

(8)Easy Installation and Maintenance

The plunger rod and seals of the plunger press pump are easy to disassemble and replace, with optional maintenance kits available for convenient daily maintenance and replacement, reducing downtime.

When Second Intelligent’s DH series online dispensers are combined with plunger press pumps, they can achieve precise dispensing of high-viscosity adhesives, significantly improving production efficiency and product quality. This combination is particularly suitable for industries such as photovoltaics, automotive, 3C electronics, aerospace, and railway transportation, which have extremely high requirements for adhesive viscosity and dispensing precision.

(1)Stable Adhesive Supply

The plunger press pump provides a stable supply of high-viscosity adhesive to the DH series dispensers, ensuring the continuity and consistency of the dispensing process. Its high-speed pneumatic switching technology and anti-icing function further enhance the stability of adhesive supply, reducing production interruptions caused by adhesive supply issues.

(2)Precise Dispensing Control

The high precision and stability of the DH series dispensers, combined with the high output pressure and large displacement of the plunger press pump, enable precise dispensing of high-viscosity adhesives. This precise dispensing control not only improves product quality and reliability but also reduces adhesive waste, lowering production costs.

(3)Strong Expandability

This combination not only excels in adhesive supply and dispensing but also offers strong expandability. It can be expanded with functions such as AOI inspection, 3D inspection, and UV curing to meet different customer needs. This expandability allows the equipment to adapt to changing production requirements, extending the equipment’s service life.