Creating Efficient Dispensing Solutions to Empower Industrial Production

In modern industrial production, dispensing processes are an indispensable part of numerous manufacturing workflows. Whether it’s the assembly of electronic products, the bonding of automotive components, or the production of other types of products, precise and efficient dispensing equipment is a key factor in ensuring product quality and production efficiency.

1. Properties of RTV Adhesive

RTV adhesive (Room Temperature Vulcanizing Silicone Rubber) is a high-performance material for sealing and bonding.

(1) Excellent Temperature Resistance

RTV adhesive can maintain stable performance under extreme temperatures, with a wide applicable temperature range from -60°C to +300°C, and some high-temperature models can even reach 350°C. This characteristic makes it perform well in high-temperature environments such as automotive engine compartments and electronic devices.

(2) Outstanding Elasticity and Flexibility

After curing, RTV adhesive has excellent elasticity, with a breaking elongation rate that can reach 150% to 700%. It can absorb stress caused by thermal expansion and contraction, preventing seal failure due to temperature changes.

(3) Good Electrical Insulation

RTV adhesive has a high dielectric strength of ≥18kV/mm, which can effectively isolate high-voltage circuits, prevent short circuits or electrical discharges, and protect electronic components.

(4) Chemical Resistance

RTV adhesive has good resistance to a variety of chemicals, including oils, acids, alkalis, and solvents, making it suitable for various harsh working environments.

(5) Environmentally Friendly

During the curing process, RTV adhesive releases almost no harmful substances and is an environmentally friendly adhesive.

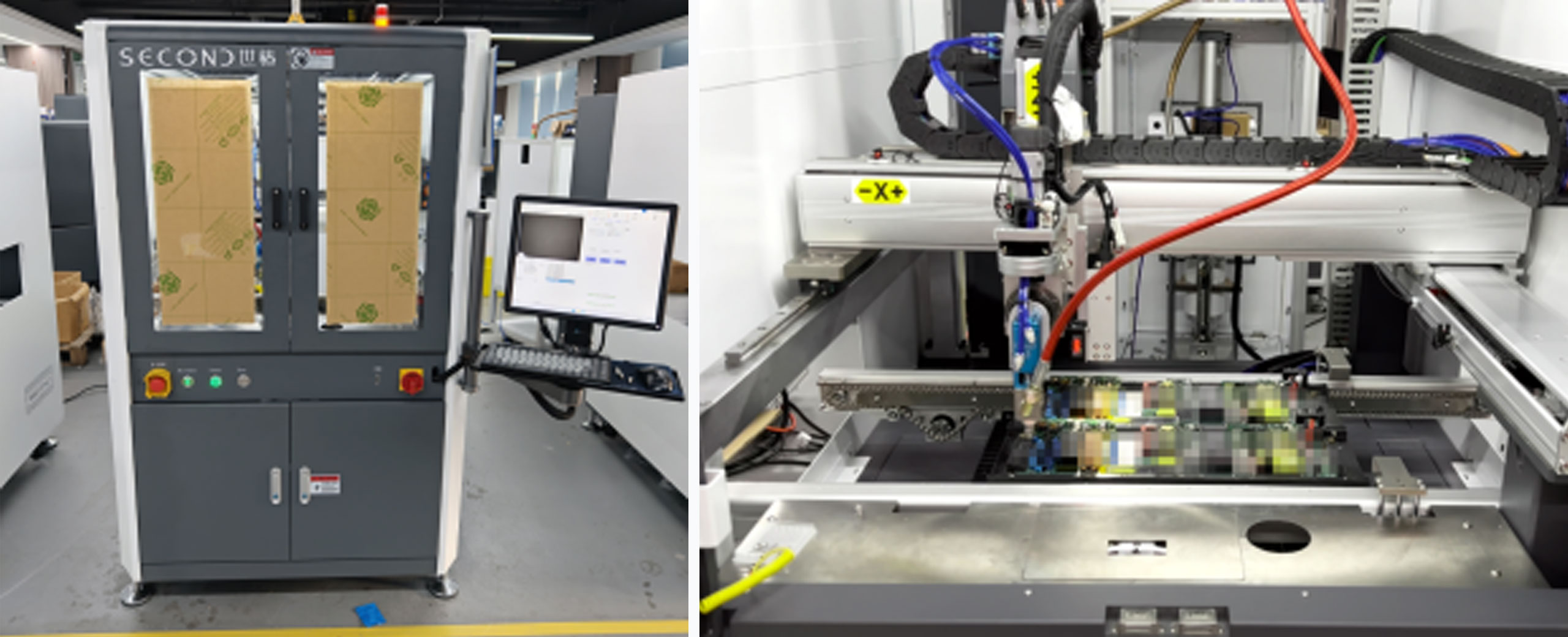

2. SEC-DH600L Dispensing Equipment

(1) High-Precision Dispensing

The SEC-DH600L dispensing equipment is equipped with an advanced CCD vision programming system that can achieve precise positioning and visual correction, ensuring the dispensing accuracy of RTV adhesive. This is particularly important in the encapsulation and sealing of electronic components, as it can effectively improve product reliability and consistency.

(2) Efficient Production

The equipment’s fast dispensing speed and automated operation, combined with the quick-curing properties of RTV adhesive, can significantly improve production efficiency. In automotive manufacturing, the dynamic flexible sealing characteristics of RTV adhesive allow it to absorb stress from thermal expansion and contraction during engine operation, extending gasket life.

(3) Multi-Functional Integration

The SEC-DH600L equipment supports visual inspection, integrating dispensing and inspection control. This not only improves production efficiency but also ensures dispensing quality and reduces the rate of defective products. The multi-functionality of RTV adhesive, such as water resistance, dust resistance, and chemical resistance, makes it play an important role in various industrial applications.

3. 2600ml Pressure Drum Module for Dispensing

In the dispensing process, the stability of the dispensing system is crucial. Second Intelligent’s 2600ml pressure drum module for dispensing, with its stable and reliable performance and wide adaptability, provides strong support for the SEC-DH600L dispensing equipment. The system uses a constant flow and constant pressure dual control mode, which can adapt to more application scenarios and processes. It has a wide range of applicable adhesive viscosities, from 1000 to 800000cps, and can handle both low-viscosity liquids and high-viscosity pastes.

The system is also equipped with a pressure sensor to achieve constant pressure control mode, ensuring the stability of the dispensing process. For 2.6L packaged RTV adhesive, the 2600ml pressure drum module for dispensing can provide stable and continuous adhesive supply, ensuring the smooth progress of the dispensing process and improving production efficiency and product quality.

4. Back-Suction Valve Dispensing

Back-suction valve dispensing is another highlight of Second Intelligent’s SEC-DH600L dispensing equipment. The back-suction valve can effectively solve the problem of fluid size head phenomenon. Its rod and sleeve structure has good sealing ability and can achieve high-precision dispensing. When handling fluids containing particles, the back-suction valve also has obvious advantages, effectively avoiding adhesive waste and contamination, and improving dispensing quality.

For 2.6L packaged RTV adhesive, back-suction valve dispensing can achieve precise adhesive control. Both the dispensing volume and speed of the adhesive can be adjusted according to actual needs. This allows the SEC-DH600L dispensing equipment to more flexibly meet various complex production requirements during the dispensing process, improving dispensing quality and reducing production costs.

5. Application Advantages

(1) Increased Production Efficiency

The combination of Second Intelligent’s SEC-DH600L dispensing equipment with the 2600ml pressure drum module for dispensing and back-suction valve dispensing has realized the automation and precision of the dispensing process. The high-precision vision positioning system and fast dispensing speed of the equipment can significantly increase production efficiency, shorten production cycles, help enterprises quickly respond to market demands, and enhance market competitiveness.

(2) Reduced Production Costs

By improving dispensing quality and production efficiency, Second Intelligent’s SEC-DH600L dispensing equipment can effectively reduce production costs. Precise dispensing control reduces adhesive waste and lowers raw material costs. Meanwhile, the automated operation of the equipment reduces manual intervention and lowers labor costs. In addition, the stability and reliability of the equipment also reduce the costs of equipment maintenance and repair, saving a considerable amount of funds for enterprises.

(3) Improved Product Quality

The high-precision dispensing and vision inspection functions of the SEC-DH600L dispensing equipment can ensure the precision and consistency of the dispensing process. This helps improve product quality and reduce the rate of defective products caused by inaccurate dispensing. High-quality products can not only enhance the reputation and brand image of an enterprise but also increase customer trust and satisfaction, bringing more business opportunities to the enterprise.

(4) Wide Range of Applications

Second Intelligent’s SEC-DH600L dispensing equipment is suitable for various industries and application scenarios, such as electronics, automotive, home appliances, and machinery. Whether it’s dispensing for small electronic components or bonding of large mechanical parts, the SEC-DH600L can provide reliable solutions. Its powerful functions and flexibility enable the equipment to easily meet various complex production requirements and satisfy the needs of different customers.