How to apply underfill adhesive dispensing to the bottom of chips on a PCB board?

Underfilling chips on PCB boards is a precision process primarily used for chips with ball grid arrays on their undersides, such as BGAs (Ball Grid Arrays) and CSPs (Chip-Scale Packages).

Below, I will explain the procedure in detail, covering its purpose, materials, equipment, steps, and precautions.

Ι.Why Use Underfill?

The primary purpose is to enhance the mechanical strength and long-term reliability of chips, especially in products operating under harsh conditions.

1.Resist Mechanical Stress:Prevents solder joint cracking caused by PCB bending, vibration, or impact. Underfill is critical for portable devices like smartphones during drops.

2.Mitigating Thermal Stress:Chips and PCB substrates (typically FR-4) have differing coefficients of thermal expansion (CTE). During thermal cycling, this mismatch generates stresses that cause solder joint fatigue failure. Underfill material evenly distributes these stresses, protecting solder joints.

3.Moisture and Contamination Barrier: The underfill gel isolates moisture and contaminants, preventing corrosion and short circuits.

4.Structural Integrity Enhancement: Bonds the chip, solder joints, and PCB into a robust, unified assembly.

SMT automatic glue dispenser SEC-DH600L

Second Intelligent high precision smt automatic glue dispenser machine apply epoxy resin to the bottom of the PCB board for underfill

Second Intelligent smt automatic glue dispenser automation SEC-DH600L has the following advantages:

● CCD visual programming precise positioning, visual correction, improve programming efficiency and dispensing accuracy;

● Chinese and English operating system, the software interface layout is clear, the operation is simple, easy to learn and understand;

● Support visual inspection, integrated control of dispensing and visual inspection, multi-purpose machine, effective control of dispensing yield;

● It can be equipped with a lin e laser scanner for 3D path guidance and flexible dispensing;

● The software can support a variety of dispensing systems and functional module applications, such as automatic needle alignment, automatic

height measurement, dispensing weighing compensation, five-axis linkage and other functions, which can effectively overcome the difficulties of

various dispensing processes and help improve quality;

II.Required Materials and Equipment

1.Core Material: Underfill Resin

Type: Typically a single-component epoxy resin requiring heat curing.

Key Characteristics:

Flowability: Must possess sufficiently low viscosity to capillary-flow into narrow chip-to-board gaps, yet remain sufficiently viscous to prevent migration to unintended areas.

Curing Conditions: Selected per product requirements; commonly cured at 130°C – 165°C for 5-15 minutes.

CTE: Its coefficient of thermal expansion should match solder materials (e.g., solder paste).

Glass Transition Temperature (Tg): A higher Tg ensures material stability at operating temperatures.

Apply epoxy resin to the bottom of the PCB board for underfill

2.Primary Equipment:

Dispenser: A precision-controlled dispensing device for accurately and uniformly applying adhesive along chip edges. Can be manual, semi-automatic, or fully automatic.

Hot Plate or Reflow/Curing Oven:

Hot Plate: Used for preheating the PCB, aiding capillary flow, and subsequent curing.

Curing Oven: Used for batch curing in high-volume production.

Microscope: Used to inspect adhesive flow after dispensing and before curing.

Cleaning Supplies: Lint-free cloths and isopropyl alcohol (IPA) for cleaning any adhesive residue.

III. Operating Procedure (Using BGA Chips as an Example)

This is a typical process flow; specific parameters should be adjusted according to the instructions for your underfill adhesive.

Prerequisites: The chip has been successfully soldered onto the PCB via SMT processes (solder paste printing, component placement, reflow soldering) and has undergone solder joint quality inspection (e.g., X-ray inspection).

1.Pre-treatment and Cleaning

Ensure the PCB has cooled completely to room temperature.

Thoroughly clean the area around the chip using IPA and a lint-free cloth to remove flux residues, dust, and grease, as these can impair adhesive flow and adhesion.

2.Preheating (Optional but Strongly Recommended)

Place the PCB on a heating platform for preheating, typically at 60°C – 90°C (refer to adhesive specifications for exact range).

Benefits of preheating:

– Reduces adhesive viscosity for improved flow, enabling faster and more complete filling.

– Removes moisture adsorbed by the adhesive and substrate.

– Minimizes bubbles formed during curing.

3.Dispensing

Secure the preheated PCB onto the dispensing machine workbench.

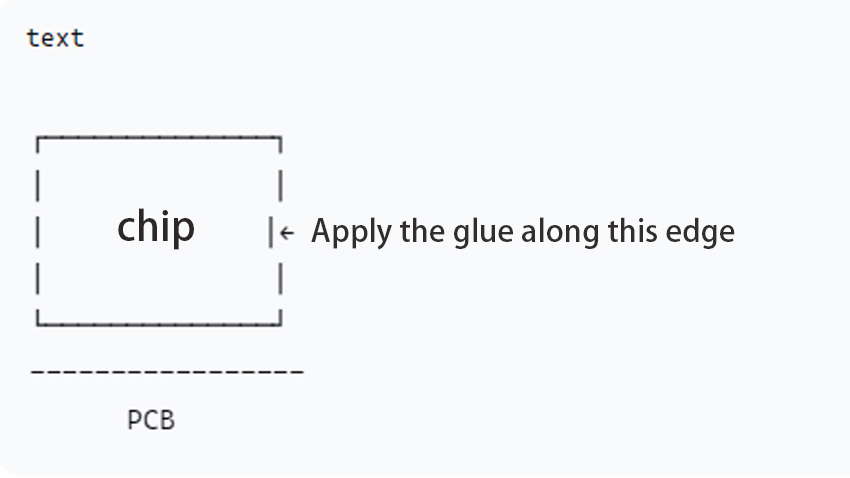

Dispense Position: Apply adhesive along either one side (L-shape) or two adjacent sides (U-shape) of the chip. Avoid dispensing along all four sides, as this traps air and prevents complete filling.

Dispensing Volume: Calculate precisely based on chip dimensions and bottom clearance height. Insufficient volume causes incomplete filling; excessive volume leads to overflow contaminating surrounding components and pads. Optimal volume allows approximately 50%-75% overflow from the opposite side of the dispensed line.

Dispensing Speed and Pressure: Adjust according to adhesive properties to ensure continuous, uniform bead formation.

Dispensing Diagram:

4.Capillary Flow

After dispensing, maintain the preheating temperature for a period to allow the adhesive to flow into the chip bottom via capillary action.

Observe the flow process through a microscope from the side until the adhesive reaches (or nearly reaches) the opposite edge. Avoid complete filling and excessive overflow beyond all edges.

5.Curing

Transfer the PCB with completed flow to the curing equipment.

Strictly follow the temperature profile provided by the adhesive supplier. A typical profile includes heating, holding, and cooling stages.

Example profile: From room temperature to 150°C, hold for 10 minutes, then cool naturally.

6.Post-Curing Cleaning and Inspection

After curing, inspect for adhesive overflow onto surrounding connectors or test pads. If present, carefully wipe with IPA (but fully cured epoxy is difficult to remove, so precise dispensing is critical).

Conduct necessary electrical testing to ensure proper functionality.

IV.Key Considerations and Common Issues

Bubbles: One of the biggest challenges. Causes include: excessive dispensing speed, improper adhesive viscosity, insufficient preheating of the PCB or adhesive, or improper dispensing paths trapping air. Preheating and controlling adhesive volume are key to avoiding bubbles.

Overflow: Excessive adhesive volume or too low viscosity can cause overflow, contaminating surrounding areas and potentially leading to difficult repairs or electrical faults.

Incomplete Filling: Insufficient adhesive volume, excessively high viscosity, poor flowability, or low PCB/adhesive temperatures can result in incomplete filling, leaving voids that fail to provide adequate protection.

Compatibility: Ensure the underfill adhesive is compatible with the chip’s packaging materials, solder ball composition, and PCB solder mask to prevent corrosion or adverse reactions.

Repairability: Once underfill is applied, rework becomes extremely difficult. It requires specialized rework stations, precise localized heating, and mechanical tools to remove the chip—a complex process prone to damaging the PCB. Therefore, underfilling is typically reserved for high-reliability chips only after confirming satisfactory soldering.

Summary

Chip underfilling is a precision process centered on:

1.Selecting suitable underfill materials.

2.Precisely controlling dispensing volume and path.

3.Optimizing preheating and curing temperature profiles.

For small-batch production and R&D, manual operation of adhesive dispensing machines and heating platforms is feasible. For mass production, fully automated dispensing machines and reflow ovens are essential to ensure consistency and efficiency.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and automatic coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.