Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

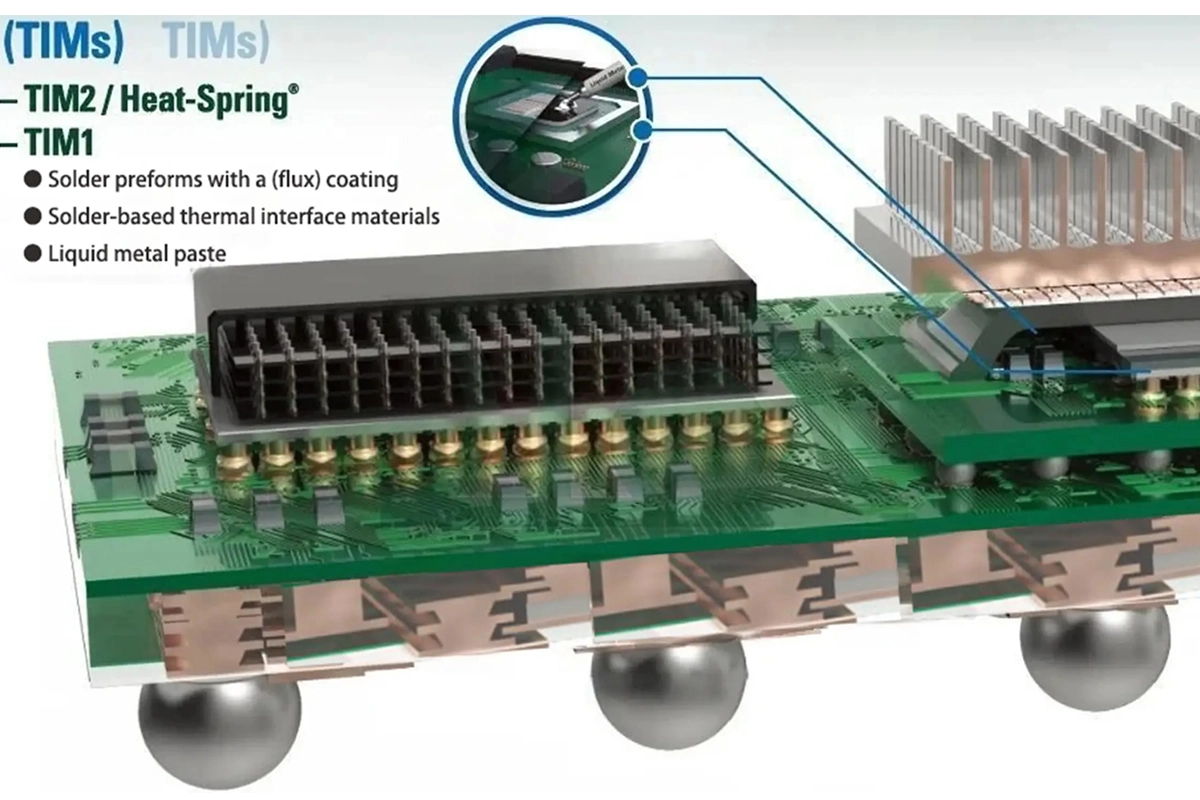

The CIPG/FIPG thermal paste dispenser is an automated device specifically designed for the precise application of thermal interface materials (TIMs), primarily used for heat management in electronic products. The CIPG/FIPG thermal paste dispenser’s application characteristics can be summarized as follows: It uses a highly automated and intelligent method to stably, consistently, and efficiently apply high-viscosity, high-performance thermal paste in a pre-set, precise three-dimensional pattern to the designated locations of complex electronic products. Deeply integrated with automated production lines, it ultimately aims to achieve a reliable, repeatable, and efficient heat dissipation assembly process in large-scale manufacturing. These features make it a critical piece of equipment for ensuring the thermal reliability and production quality of high-end electronic products.

Automatic feeding by platen pump + Glue processing in transit tanks

+ piston pump for metering + Dispensing Valve

The lithium battery cell coating process is a precise and continuous core manufacturing process. Its core lies in coating the positive and negative electrode slurries of the battery onto the metal foil current collector with extremely high consistency and a preset thickness through precise methods such as slit extrusion. The coating is then immediately placed into a segmented temperature-controlled oven for drying to cure the coating and evaporate the solvent. The entire process ensures that the areal density, blank size and surface quality of the electrode sheet are uniform and stable through fully automatic tension control, online real-time thickness measurement and defect detection, thereby preparing a reliable and defect-free electrode substrate for subsequent processes.

RTV effectively suppresses the movement of plug-in components.

●Easy to operate, simple and easy to use

●Glue stirring, prevent precipitation, vacuum degassing, nitrogen protection

●Piston rod glue supply, first-in-first-out, ceramic lever, high wear resistance

●TC distribution valve, few parts, easy to clean

The lithium battery cell glue coating machine has the following technical features:

● it adopts the Graco pressure plate pump with NXT technology and the high-sealing transfer barrel to achieve heating, stirring, vacuum degassing of the glue, low liquid level alarm, and non-stop feeding;

● it adopts the dual servo metering system PR-Xv, which is designed for abrasion resistance, first-in-first-out materials, stable glue flow, high precision and high repeatability;

● it adopts the modular design of the distribution valve TC Valve to reduce maintenance time and cost, and can handle a wide range of materials;

● it has motor torque monitoring, fluid pressure detection, automatic pre-punching and pressure relief functions; fifth, it is equipped with a flow meter to monitor the glue output and glue output ratio in real time; sixth, it adopts an information management system to realize the transmission and storage of process data and is compatible with the MES system.

The lithium battery box glue coating machine has the following technical features:

● it adopts the Graco pressure plate pump with NXT technology and the high-sealing transfer barrel to achieve heating, stirring, vacuum degassing of the glue, low liquid level alarm, and non-stop feeding;

● it adopts the single servo metering system EFR, which has precise glue coating, a wide range of uses, easy operation and easy maintenance;

● it adopts a high-precision drive motor to directly control the pump without excessive maintenance;

● the modular design of the distribution valve MD2 reduces maintenance time and cost, and can handle a wide range of materials;

● the highly wear-resistant metering Z pump has a mechanical connection, accurate ratio, and continuous glue discharge; sixth, it uses the advanced display module ADM, which is easy to operate and highly integrated; seventh, it is equipped with a flow meter to monitor the glue output and glue output ratio in real time; eighth, it adopts an information management system to realize the transmission and storage of process data and is compatible with the MES system.

Do not hesitate to contact us for further information, thanks in advance for your support!