Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

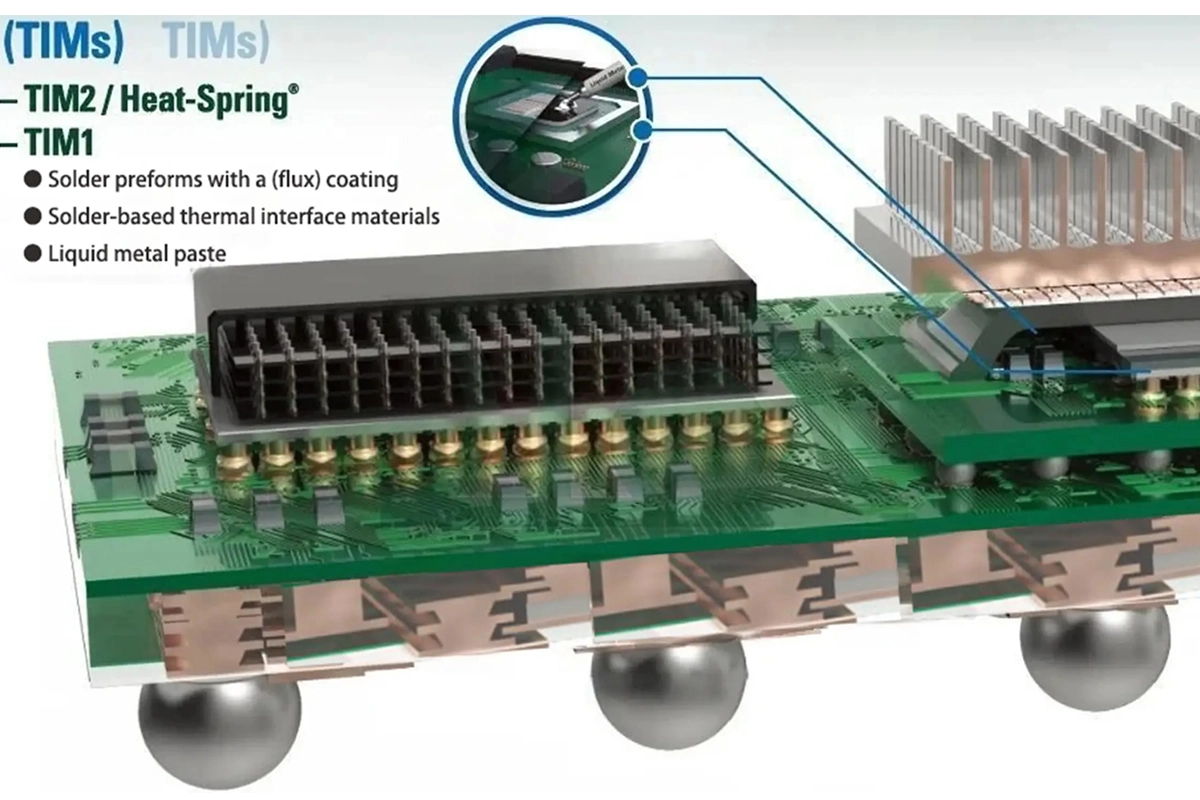

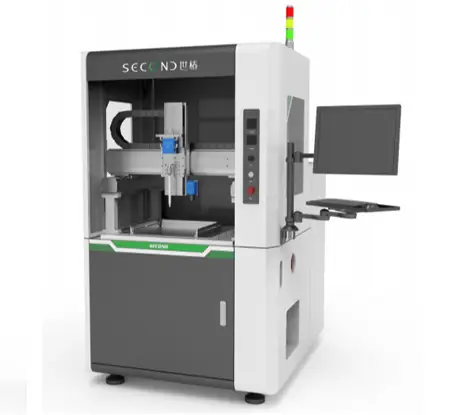

The CIPG/FIPG thermal paste dispenser is an automated device specifically designed for the precise application of thermal interface materials (TIMs), primarily used for heat management in electronic products. The CIPG/FIPG thermal paste dispenser’s application characteristics can be summarized as follows: It uses a highly automated and intelligent method to stably, consistently, and efficiently apply high-viscosity, high-performance thermal paste in a pre-set, precise three-dimensional pattern to the designated locations of complex electronic products. Deeply integrated with automated production lines, it ultimately aims to achieve a reliable, repeatable, and efficient heat dissipation assembly process in large-scale manufacturing. These features make it a critical piece of equipment for ensuring the thermal reliability and production quality of high-end electronic products.

Automatic feeding by vacuum + Glue processing in tanks

+piston pump for metering+Vacuum Environment Potting

+Automatic pallet entry and exit

RTV effectively suppresses the movement of plug-in components.

●Fully automatic vacuum potting production line with powerful functions;

●Vacuum potting, fixture reflow, automatic curing oven baking and other functions;

●MES data collection and uploading, integrating automation, intelligence and informatization

Accurate ratio, integrated glue mixing and filling,

to achieve truly fully automated mixing, avoid manual mismatching,

resulting in waste and scrap. Accurate positioning,

fast speed, simple and convenient adjustment, strong versatility,

conventional LED, electronic appliances,

handicrafts can be used. Simple programming, simple operation,

can be used with assembly lines,

anyone can operate the counting function, non-standard mode,

bottom glue mode, liquid level alarm

Accurate ratio, integrated glue mixing and filling,

to achieve truly fully automated mixing, avoid manual mismatching,

resulting in waste and scrap. Accurate positioning,

fast speed, simple and convenient adjustment, strong versatility,

conventional LED, electronic appliances,

handicrafts can be used. Simple programming, simple operation,

can be used with assembly lines,

anyone can operate the counting function, non-standard mode,

bottom glue mode, liquid level alarm

Accurate ratio, integrated glue mixing and filling,

to achieve truly fully automated mixing, avoid manual mismatching,

resulting in waste and scrap. Accurate positioning,

fast speed, simple and convenient adjustment, strong versatility,

conventional LED, electronic appliances,

handicrafts can be used. Simple programming, simple operation,

can be used with assembly lines,

anyone can operate the counting function, non-standard mode,

bottom glue mode, liquid level alarm

Do not hesitate to contact us for further information, thanks in advance for your support!