This is an automatic two-part materials epoxy resin dispenser. It able to perform automatic materials refilling, degassing, metering, mixing, and potting homogenously, continually, and automatically. It equips with a three-axis automatic dispensing robotic system, this allows the control software to dispensing almost any patterns, such as points, lines, circles, arcs, and other 3-dimentional trajectories precisely. In addition, at the same time complete the automatic proportioning and automatic mixing of the two-component glue on demand. The machine also can install agitate system for material stirring; heating system for material flow; cleaning system, anti-clogging system, and other functions to support for better and effective works.

Automated three components materials dispenser SEC-8900E

Description

Our homepage is under construction, more information will be posted, welcome to email us for specific inquiry, thx

Features

Specification

Features:

Unique control software

With vacuum feeding, vacuum deaeration, stirring

Heating, automatic cleaning

Advantages:

Simple operation

Greatly saves the manual mixing time

Improves efficiency

Saves costs and cost-effective

PRODUCT DETAILS

Supporting Systems

(1)Compared with the traditional two-component glue filling machine, this equipment is suitable for the automatic mixing and automatic mixing of the three-component glue, and it has the functions of vacuum feeding, vacuum defoaming, stirring, heating and automatic cleaning.

(2)The operation issimple, which greatly saves the manual mixing time, improves efficiency, saves costs, and has a high cost performance!

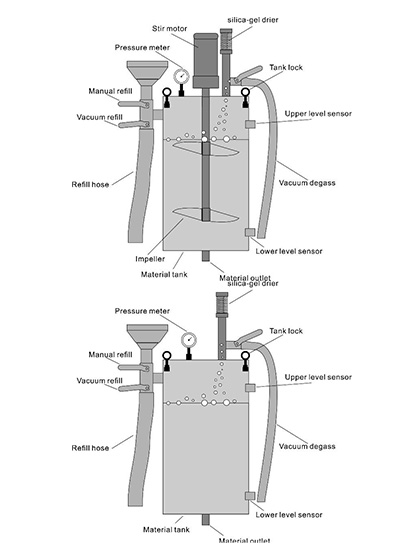

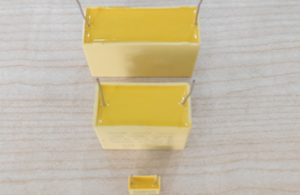

Material Tanks

(1)In order to achieve the highest stability and accuracy, the material tank of the machine is well-sealed

(2)With locking devices and valves, and each machine is equipped with material tanks of different capacities

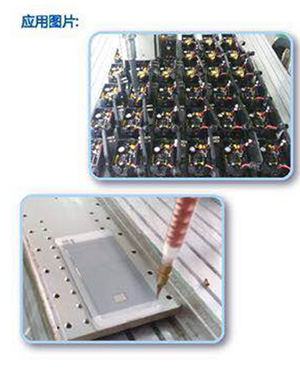

MANUFACTURING

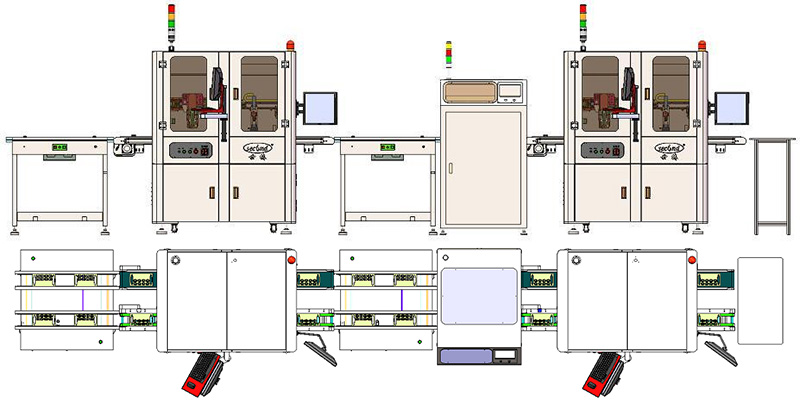

Salcomp – 2 sides glue dispensing, curing, belt reflux automated production

How It Works

Automated high viscosity thermal interface material deispensing machine, Second’s unique control software can follow the set points, lines, circles, arcs and other trajectories

CASE

Compared with the traditional two-component glue filling machine, this equipment is suitable for the automatic mixing and automatic mixing of the three-component glue, and it has the functions of vacuum feeding, vacuum defoaming, stirring, heating and automatic cleaning.

.jpg)

SOLUTION

Project

The LED Drive Power, Machine SEC-3030C

Project Background

The LED drive power supply is a power converter that converts the power supply into a specific voltage and current to drive the LED to emit light. The Shichun glue potting equipment is used in the LED drive power supply to play a role in heat dissipation, moisture proof, waterproof, and flame retardant.

Project Features

Heat dissipation, moisture proof, waterproof, flame retardant

Project Advantages

1. Three-axis linkage, capable of making arbitrary points, lines, arcs, circles, three dimensions, etc.;

2. Dynamic mixing, uniform mixing, no dripping;

3. Nano ceramic screw pump, good wear resistance;

4. 12CC screw pump, fast glue output speed, 30g/sec;

5. It has the function of pump pressure detection to ensure quality and safe production;

6. It has dynamic fault detection function to ensure quality and safe production;

7. Optional large-capacity storage barrel, saving feeding time and improving efficiency;

8. Online glue filling, without manual operation, automatic connection operation.

FAQ

We are direct manufacturer.

Generally, we pack our goods with proper wooden box. However, if client has special requirment, we can customize.

Depends on terms and conditions, negotiable.

Yes, we can produce according to the tested result. We can also product base on your design.

Yes, we will test 100% before delivery.

We keep good quality and competitive price to ensure our customers benefit. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Dispensing machine is an automatic machine and equipment that specializes in controlling fluid and dripping, coating, and potting the liquid on the surface of the product or inside the product. The glue dispenser is mainly used for glue and paint in the product process.

Glue dispensers are generally suitable for small products or electronic components, which are more precise; the products of potting dispensers are generally larger.

As long as it is a fluid with a viscosity within a certain range, it can be operated. The glue generally used in the dispenser includes red glue, hot melt glue, silica gel, grease and so on.

Technical Parameter

| Model | SEC-8900E |

| Operate action | Single, auto, continue line |

| Working viscosity | <100000PCS |

| Ration accuracy | ±2% |

| Output ratio | ±2% |

| The mixing ratio | 100:100~100:20 or 100:20~100:10 adjustable |

| Spit glue speed | 1g/sec~15g/sec or 5g/sec~30g/sec |

| Operating method | PLC + Touchscreen |

| Anti clogging setup time | 0-100Sec |

| Measurement method | Servo motor + gear pump/screw pump or servo motor + piston pump |

| Transfer method | Servo motor +ball screw |

| Power supply | AC220V 50HZ 2.5KW |

| Machine size | 1745(L) ╳885(W)╳1550(H)mm |

| Weight | About 300KG |

| Working environment | Temperature: 0-40℃, Humidity: 20-90% |

Main configuration:

| Part | Unit | QTY | Note |

| Movement Control | Set | 1 | Second Original |

| Touchscreen | Set | 1 | Weinview |

| PLC | Set | 1 | Mitsubishi |

| Material Tank | Set | 2 | Tank Size (option) |

| Metering Pump | Piece | 2 | Screw Pump/Gear Pump/Piston Pump (according to materials) |

| Mixing Valve | Piece | 1 | Static or Dynamic Valve |

| Heating System | Set | 2 | Option |

| Pressure Monitor | Set | 2 | Option |

| Flow Meter | Set | 2 | Option |

INQUIRY FORM