Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

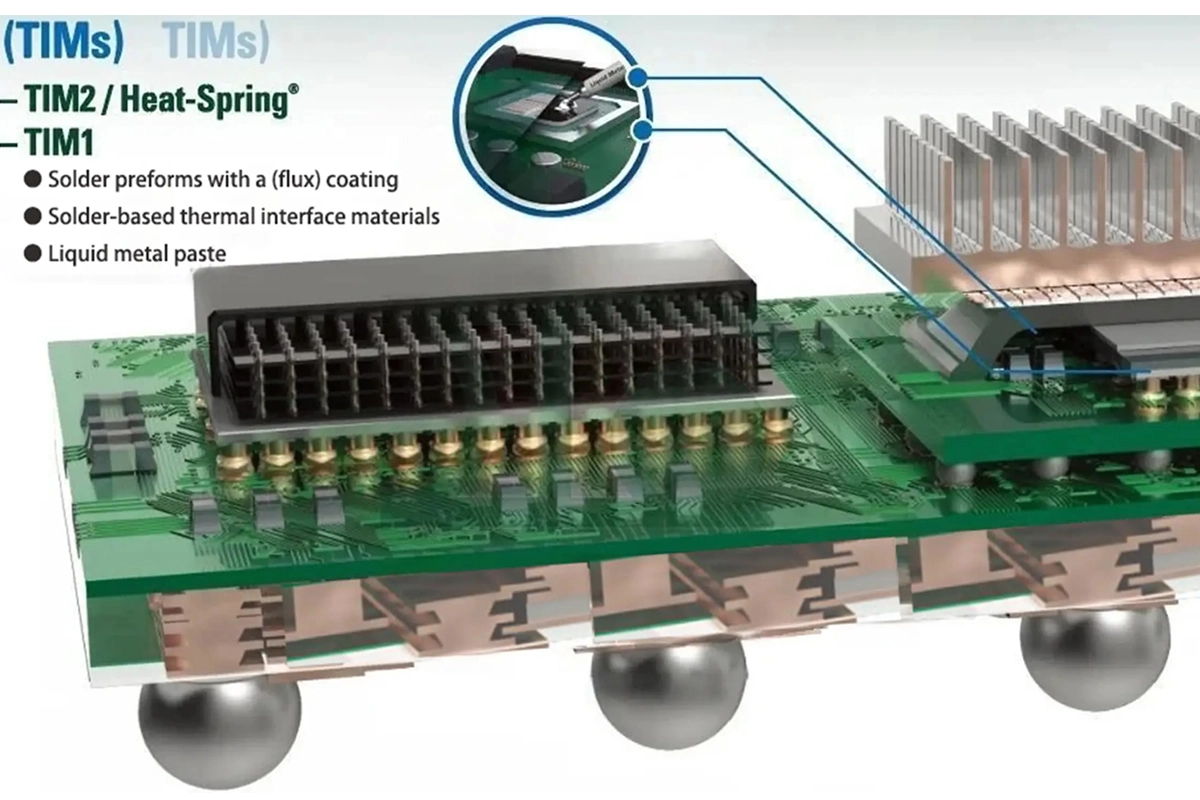

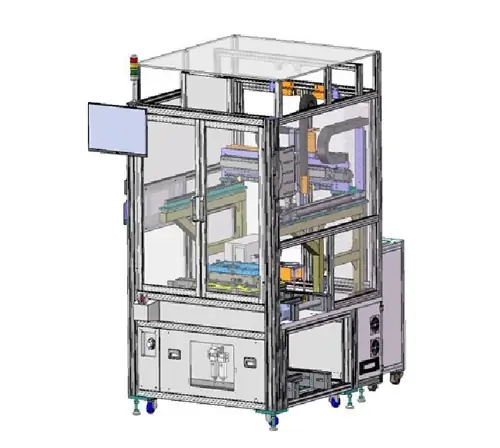

The CIPG/FIPG thermal paste dispenser is an automated device specifically designed for the precise application of thermal interface materials (TIMs), primarily used for heat management in electronic products. The CIPG/FIPG thermal paste dispenser’s application characteristics can be summarized as follows: It uses a highly automated and intelligent method to stably, consistently, and efficiently apply high-viscosity, high-performance thermal paste in a pre-set, precise three-dimensional pattern to the designated locations of complex electronic products. Deeply integrated with automated production lines, it ultimately aims to achieve a reliable, repeatable, and efficient heat dissipation assembly process in large-scale manufacturing. These features make it a critical piece of equipment for ensuring the thermal reliability and production quality of high-end electronic products.

Visual positioning + laser height measurement + syringe dispensing

Dispensing consistency control — Profile control capability — Path accuracy and corner handling — Stringing and dispensing control — Bubble control and management — Temperature stability management

The process characteristics of CIPG/FIPG dispensing machines are essentially centered around two key objectives: “shape control” and “property control”:

Shape control: The macroscopic geometry of the rubber strip is controlled through precise coordination of trajectory, speed, pressure, and nozzle.

Property control: The microscopic quality (no bubbles, no strings) and physical properties (stable thermal resistance) of the rubber strip are ensured through temperature, degassing, back suction, and consistency control.

RTV effectively suppresses the movement of plug-in components.

●The control software is easy to operate and program;It has the functions of drawing points, lines, surfaces, arcs, circles, irregular curves, continuous interpolation and three-axis linkage;

●Powerful PC compatibility, with Logoshop software, can import various file formats (such as .NC, .AI, .DXF, .JPG, .BMP, scanners, etc.) generated by mainstream design software (such as Jingdiao, AutoCAD, CoralDraw, etc.);

●Equipped with 130W pixel CCD visual software, it has a correction function, and the product can be automatically corrected if it has a certain range of offset;

●The equipment is equipped with laser height measurement to solve the problem of product deformation and dispensing The equipment is equipped with a low liquid level alarm function to remind the operator to change the glue in time;

●The equipment is equipped with an automatic needle alignment function to avoid poor dispensing after changing the needle;

●The equipment is equipped with a low air pressure alarm All doors of the equipment are equipped with safety door locks;

●The equipment can be adapted to visual positioning, product deformation correction, low-temperature plasma cleaning, automatic dispensing, dispensing effect detection, automatic glue quantity inspection, RFID station passing, automatic needle correction, MES system and other rich functions

Do not hesitate to contact us for further information, thanks in advance for your support!