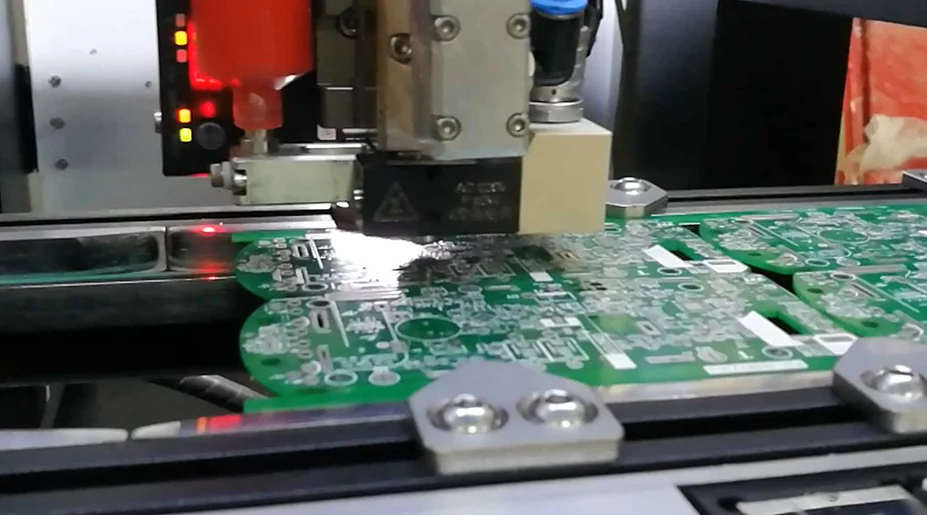

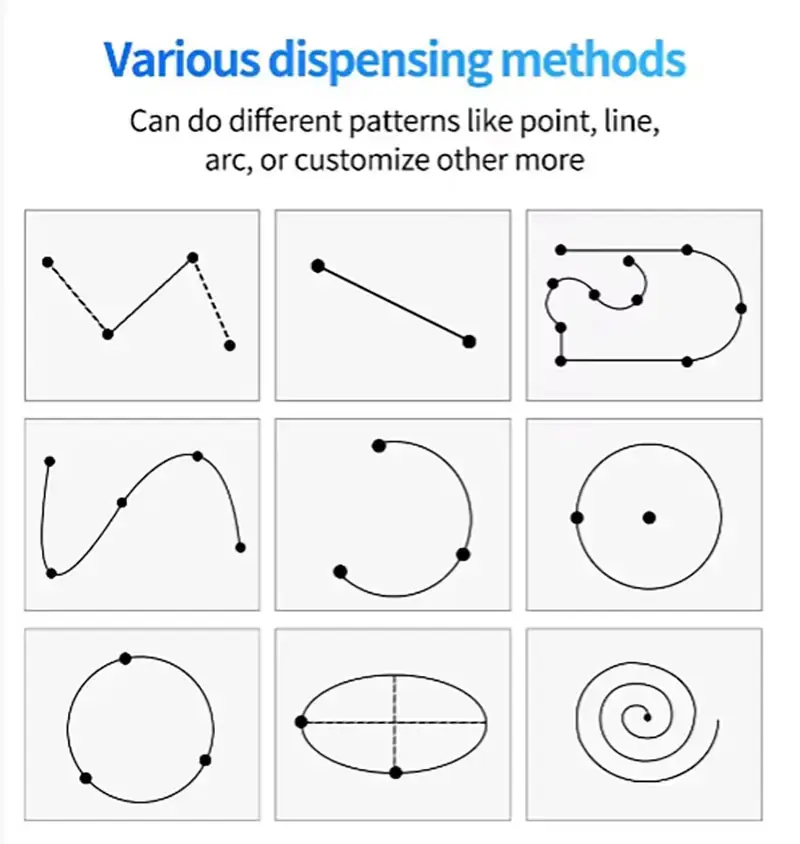

Automated high viscosity thermal interface material deispensing machine, Shichun‘s unique control software can follow the set points, lines, circles, arcs and other trajectories

Feature:

- One-piece aluminum casting molding

- Strong structure

- Stable and user friendly operation

- Allow quick changeover

PRODUCT DETAILS

Supporting System

- The machine equips with 3 axis robotic system. It is operated by Second originally developed software, windows based.

- It can not only set trajectories such as set points, lines, circles, and arcs, but also has advanced functions such as three-dimensional potting through program setting.

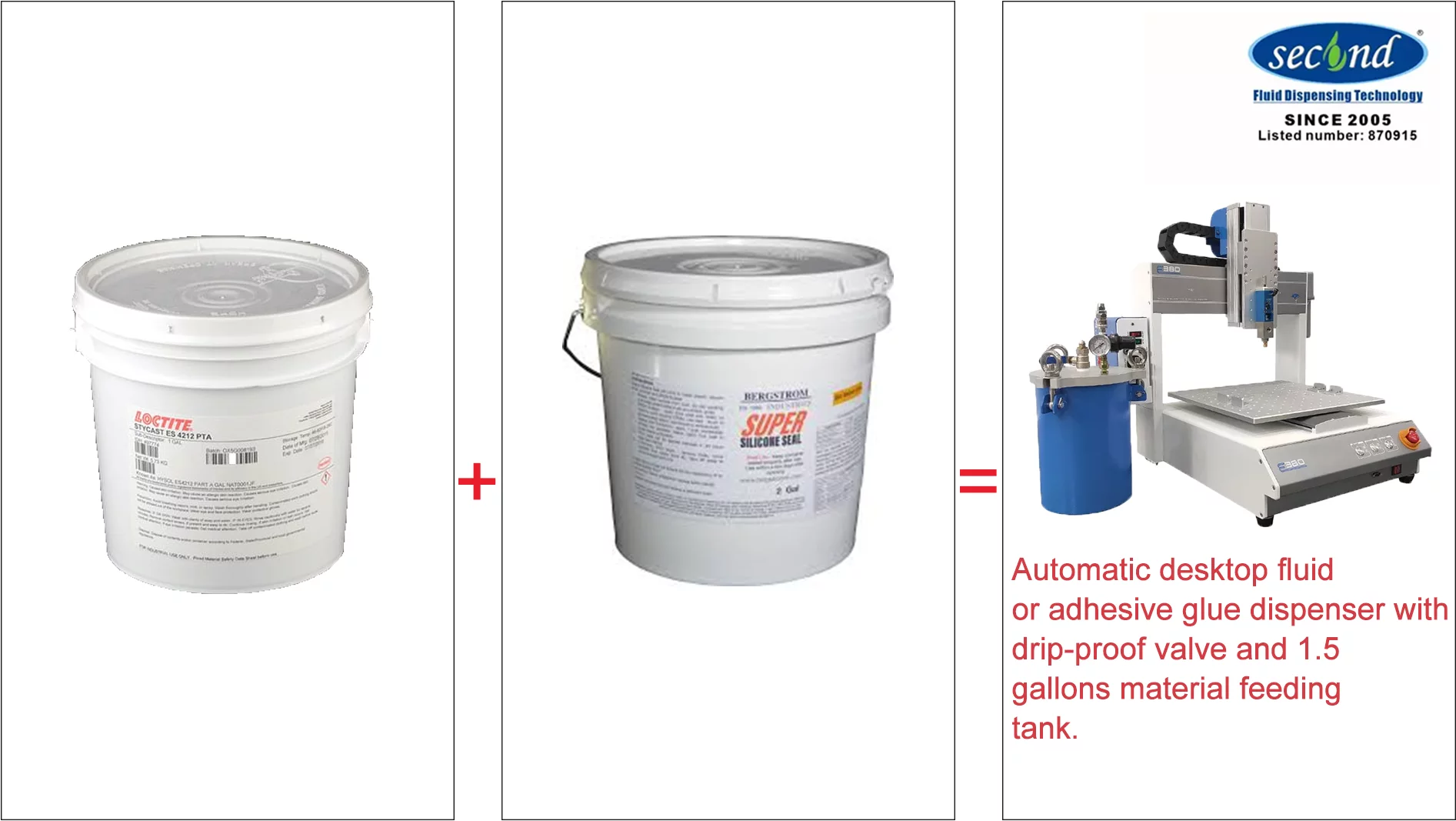

Material Tanks

- In order to achieve the highest stability and accuracy, the material tank of the machine is well-sealed

- With locking devices and valves, and each machine is equipped with material tanks of different capacities

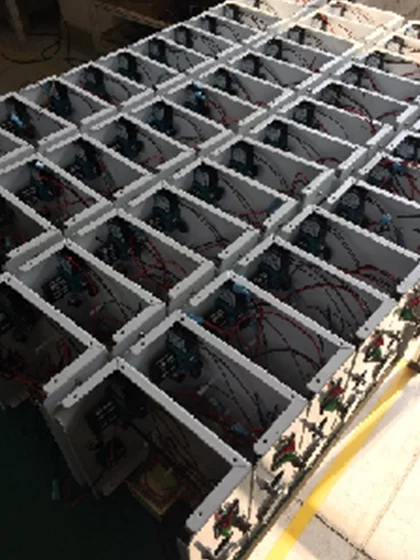

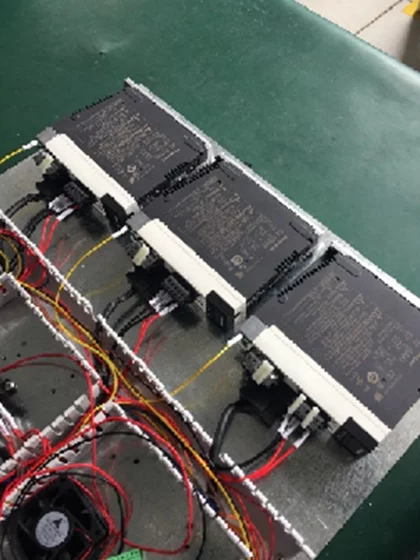

MANUFACTURING

It builds various types of dispensing valves, and controlers

How It Works

CASE

1.5 gallons fluid or adhesive glue. Materials can be refilling into this 1.5 gallon tank and feed out to dispensing.

Dispensing process:

Multi-valve picture display

-300x300.webp)