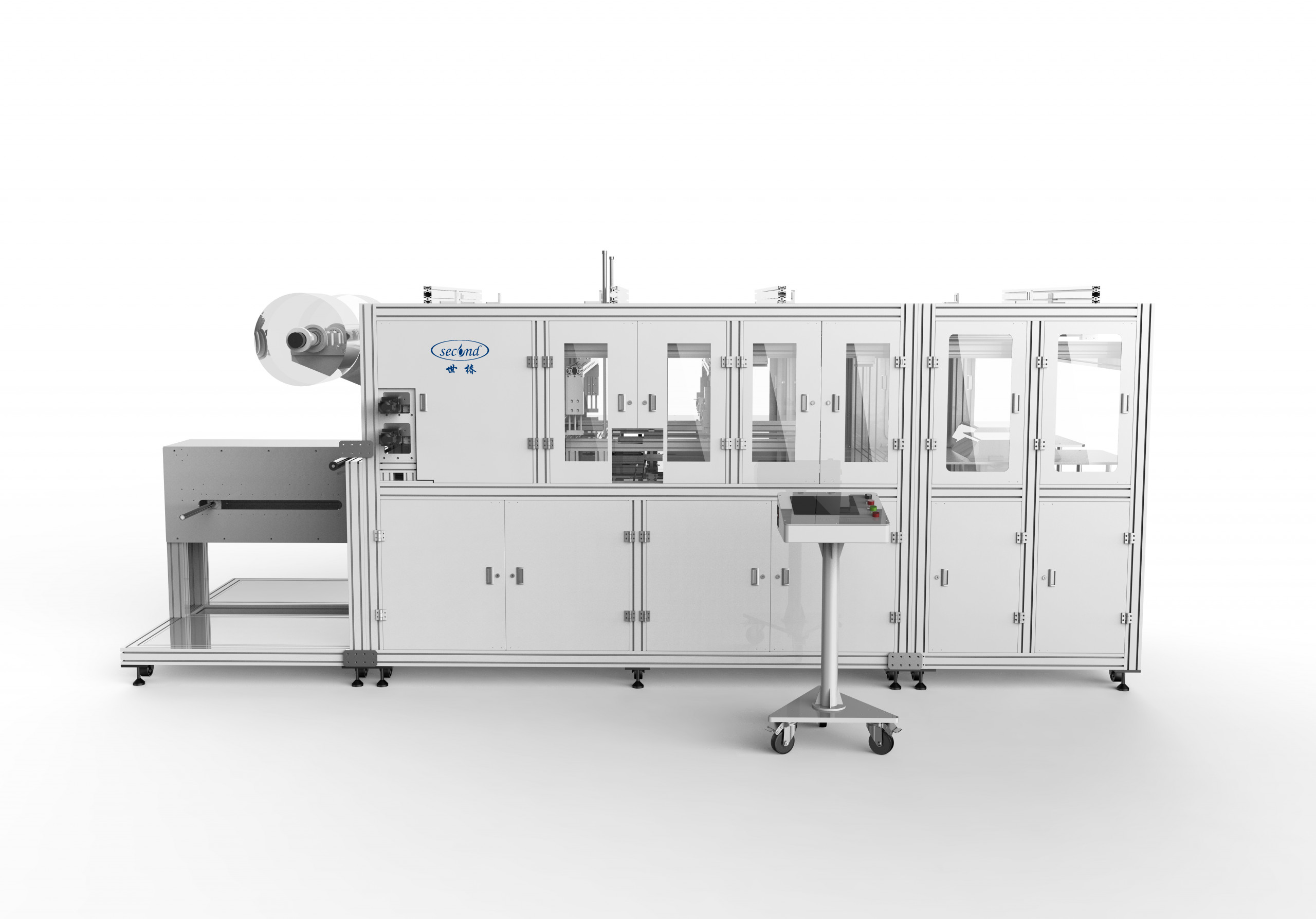

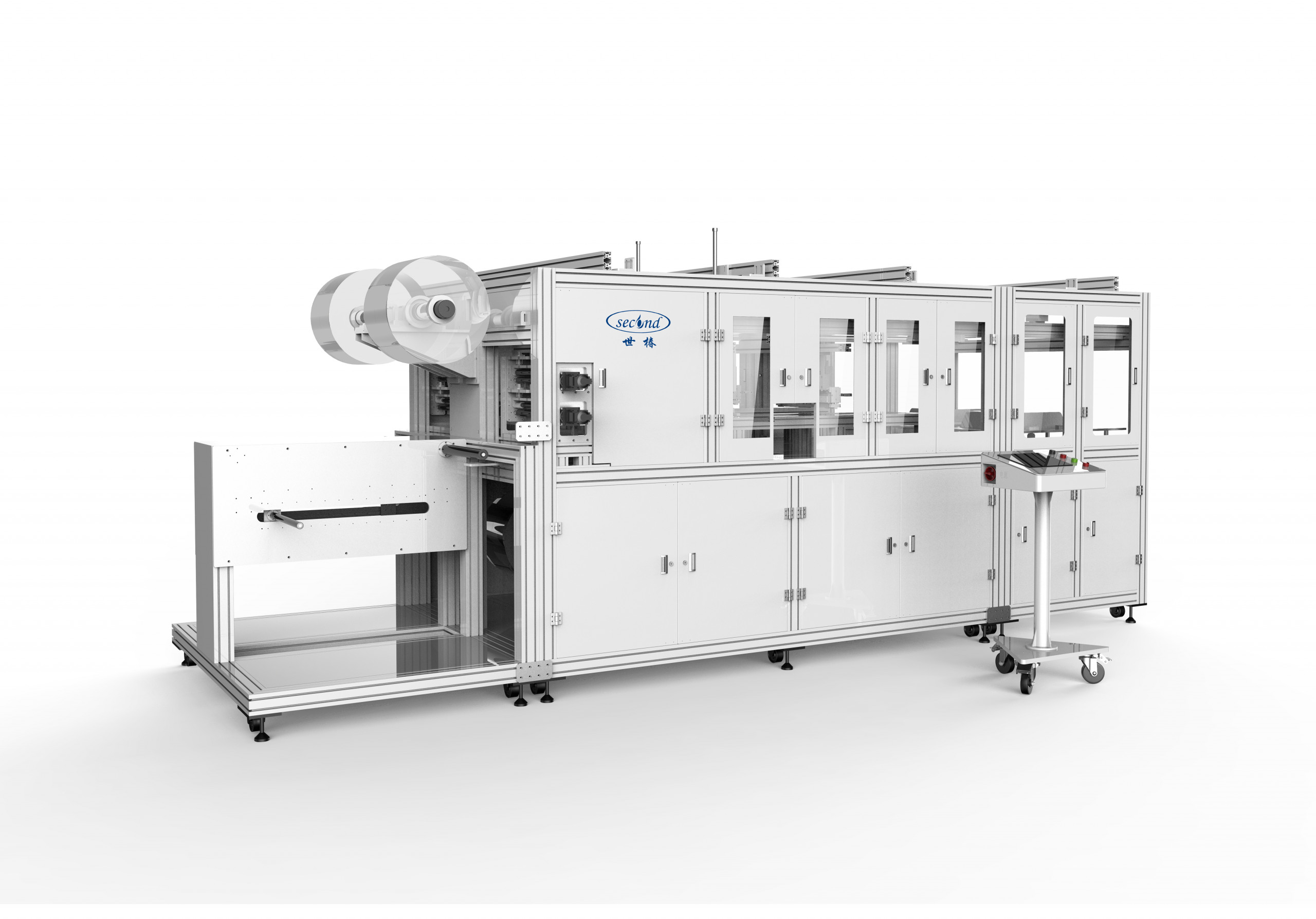

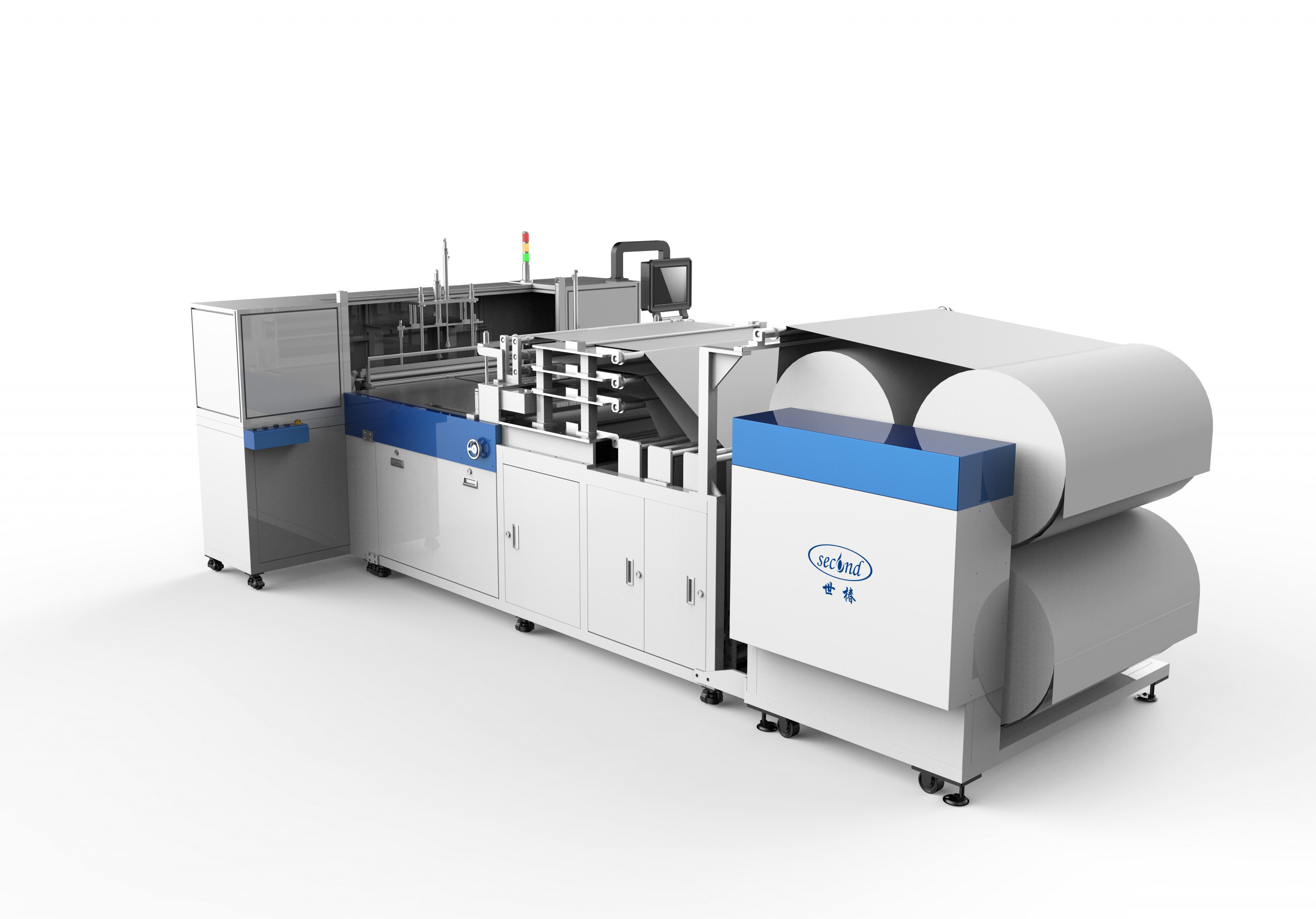

This is a fully automatic operating machine. It is high capacity production machine equips with dual-working stations for prepping the domestic RO leaf, tricot pads.

Automatic industrial Reverse Osmosis tricot leaf prepping machine SEC-S8060WG

Description

Introduction:

This is a very functional machine, which suits for a variety of household RO element leaf, tricot prepping processes. It is especially suitable for large-capacity element production factories use because of its accurate and efficient.

How it works?

The engineer only needs to install the membrane material roll and spacer material, set the parameters, and the equipment will automatically run to complete the operation after one-key startup, without manual intervention. The system can store a variety of models in advance, set it once, and recall it later for use. The equipment design is user-friendly and easy to operate, once realizing the width of the raw material 220-340mm, set the length and position parameters, and the double working stations will run at the same time, with high efficiency and neat folding. One person can watch multiple sets of equipment at the same time. When the materials are used up, an automatic alarm will prompt replacement.

Specification

Model | SEC-S80WD |

Suitable RO cartridge element sizes | 1810-3313 |

Working mode | Automatic |

Membrane material roll diameter (workable range) | Φ90-500mm |

Membrane width (workable range) | 220-340mm |

Slitting precision | ±0.25mm |

Slitting length range | 1100-2200mm |

Stacking speed | 0-500mm/s |

Material unloading | Automatic unloading |

Leaf storage quantity | ≤60片 |

Alarm signal | Material shortage alarm |

Control system | PLC |

Capacity per hour | 200PCS/H |

Power consumption | 5KW |

Power supply | AC220V/50HZ |

Machine dimensions | L4800mm*W1650mm*H1800mm |

Machine weight | 700kg |

MANUFACTURING

This is RO and water filter fabricating machines and equipment production floor. From the house to industrial types of RO, they were produce in this department.

The machine is effective and efficient for different type of element withing the ranges.

.jpg)

FAQ

We are direct manufacturer.

Generally, we pack our goods with proper wooden box. However, if client has special requirment, we can customize.

Depends on terms and conditions, negotiable.

Yes, we can produce according to the tested result. We can also product base on your design.

Yes, we will test 100% before delivery.

We keep good quality and competitive price to ensure our customers benefit. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

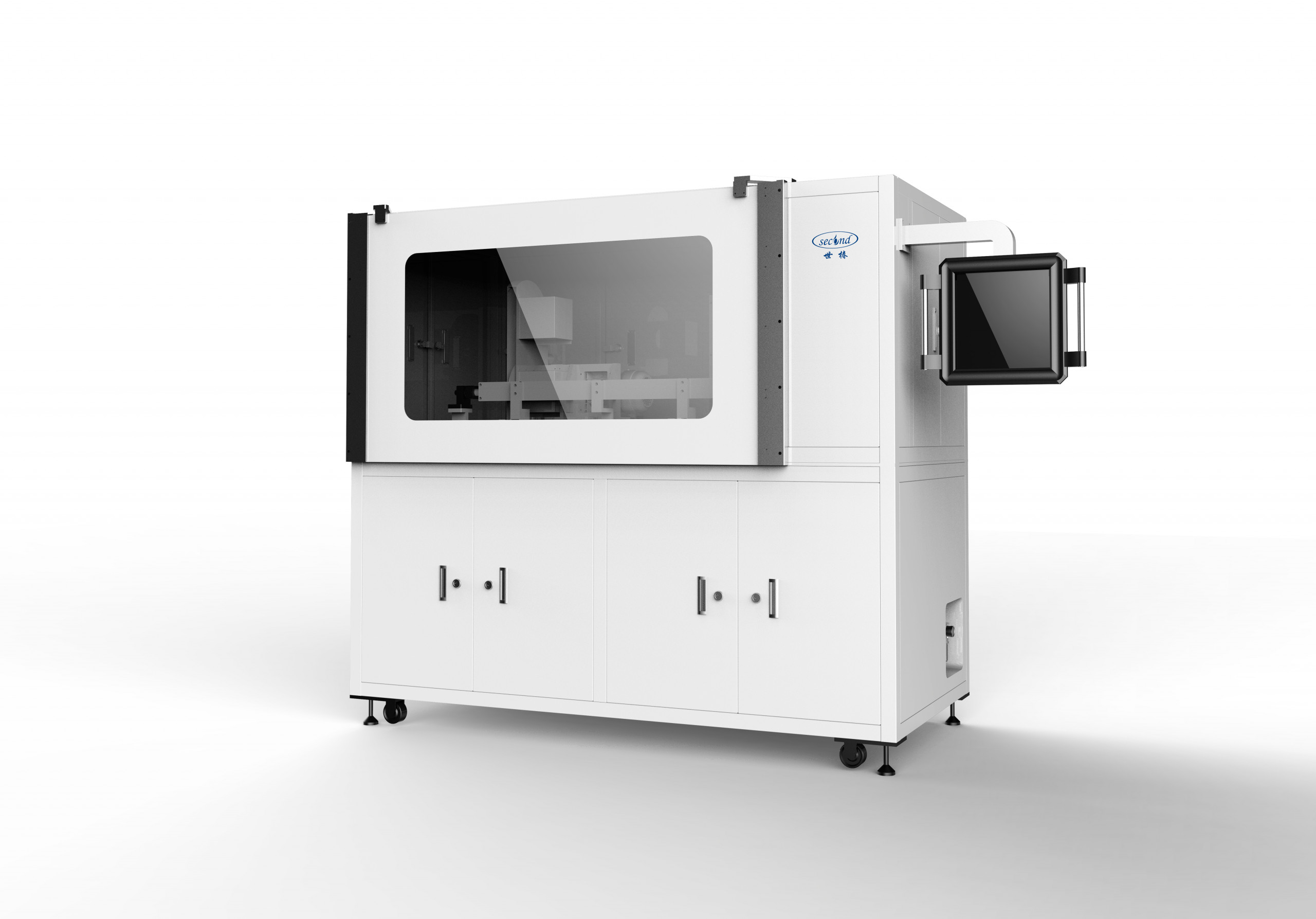

Dispensing machine is an automatic machine and equipment that specializes in controlling fluid and dripping, coating, and potting the liquid on the surface of the product or inside the product. The glue dispenser is mainly used for glue and paint in the product process.

Glue dispensers are generally suitable for small products or electronic components, which are more precise; the products of potting dispensers are generally larger.

As long as it is a fluid with a viscosity within a certain range, it can be operated. The glue generally used in the dispenser includes red glue, hot melt glue, silica gel, grease and so on.

Technical Parameter

| Model | SEC-1880GL |

| Suitable element | 1810 series-3313 series |

| Material width | 330mm(MAX) |

| Core pipe loading | Automatic |

| Unloading | Automatic |

| Working range | 1300mm(X)*500mm(Y)*100mm(Z) |

| Mixing method | Dynamic mixing, fast, and cleanable |

| Max speed | 0-500mm/sec |

| Welding method | Ultrasonic welding |

| Resolution | 0.01mm |

| Dispensing control | Stepper motor + gear pump servo motor + ceramic piston pump |

| Repeat accuracy | ±0.025mm |

| Movement control | PC + motion control, PLC |

| Mixing ratio | 1:1-5:1; adjustable numeric number |

| RO Material roll diameter | Ø40-90mm |

Main configuration:

| Description | Unit | QTY | Note |

| Driving motor | Set | 5 | Servo motor |

| Carrier membrane feeding system | Set | 1 | Magnetic control + Air expansion shaft |

| Ultrasonic welding | Set | 1 | Second original |

| Guide rail | Set | 5 | Taiwan TBI, Hiwin |

| Industrial computer | Set | 1 | Second Original |

| Monitor | Unit | 1 | Dell |

| PLC touchscreen | Set | 1 | PLC, Weinview |

| Movement control | Set | 1 | Second Original |

| Cylinder | Set | 2 | SMC |

INQUIRY FORM