Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

Accept production capacity customization and different process combinations.

Conveying system, realize product material separation.

Glue dispensing system, has all the functions of glue dispensing machine.

Glue break detection system, detects whether there is a breakpoint in the glue line after glue dispensing.

Bonding system, realizes the bonding of single board.

Pressurization system, applies a certain pressure to the single board in the fixture to achieve complete bonding of the single board.

Curing system, realizes water field bonding curing and airtight sealing glue line curing.

Glue type detection system, detects the width and height of the glue line, can be sampled or fully inspected.

Material collection system, collects bipolar plates into the material frame.

Information management system, can realize the transmission and automatic storage of process data such as QR code reading, glue dispensing speed, pressure, and capacity, is compatible with MES system, and supports one-click backup.

Main process

Realizes the packaging and detection of graphite plates, composite plates, and metal plates

Anode plate feed→Water field dispensing→ Glue break dection→ NG Product Cache→ Cathode/Anode Plate Lamination

→ Heat curing→ Polar Plate A-side Dispensing→ Side A Gum Type Inspection→A-side curing→ Flip 180°→ Polar plate B-side dispensing

→ B-side gel type detection→ B-side curing→ lower the material flow

RTV effectively suppresses the movement of plug-in components.

●Accepts production capacity customization and different process combinations. The line can be operated as a whole line or as a single machine offline;

●The whole line realizes water field and air field sealing;

●The control system is an independent, modular, standardized program;

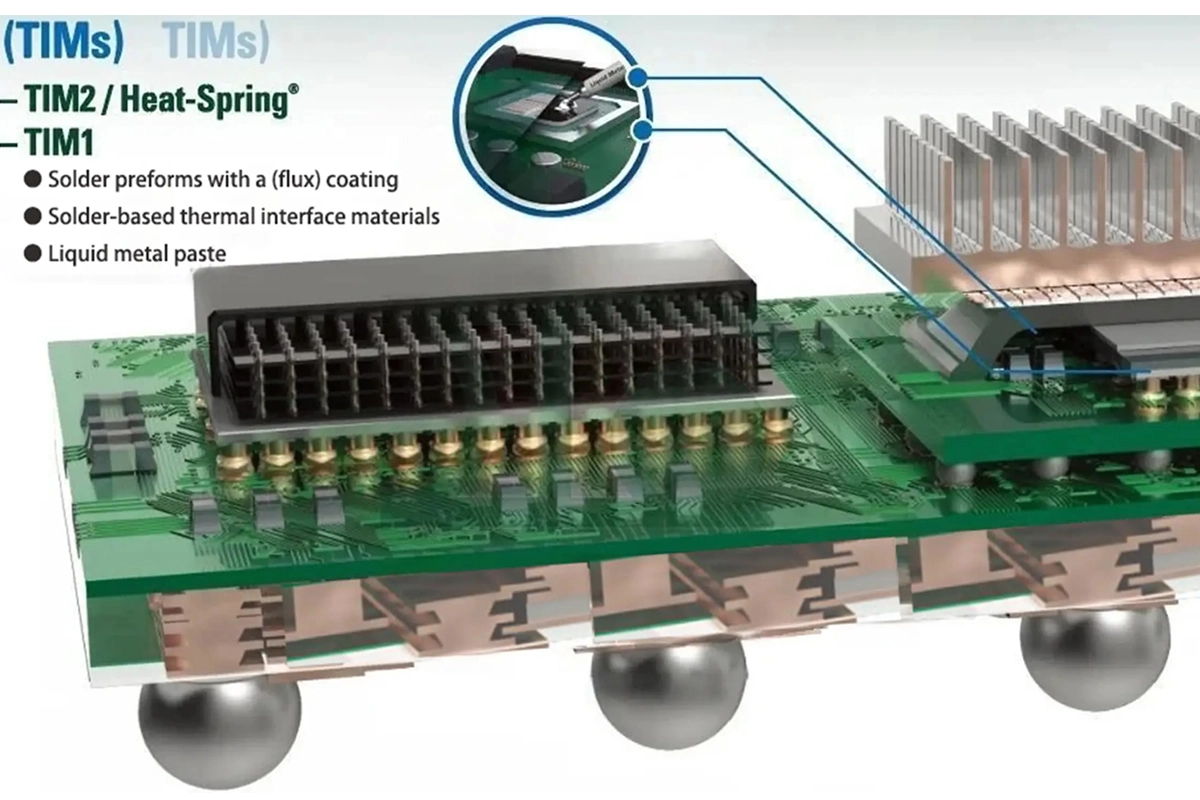

Accurate ratio, integrated glue mixing and filling,

to achieve truly fully automated mixing, avoid manual mismatching,

resulting in waste and scrap. Accurate positioning,

fast speed, simple and convenient adjustment, strong versatility,

conventional LED, electronic appliances,

handicrafts can be used. Simple programming, simple operation,

can be used with assembly lines,

anyone can operate the counting function, non-standard mode,

bottom glue mode, liquid level alarm

Do not hesitate to contact us for further information, thanks in advance for your support!