Feature:

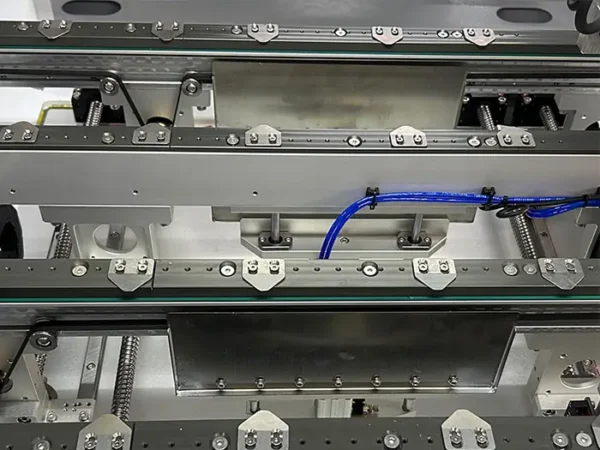

- The platfomm and X/Y module base are made of mineral casting, and the key surfaces are processed by grinding to ensure higher precision and stability.

- Gantry typestructure, withstand large loads, stable structure, and

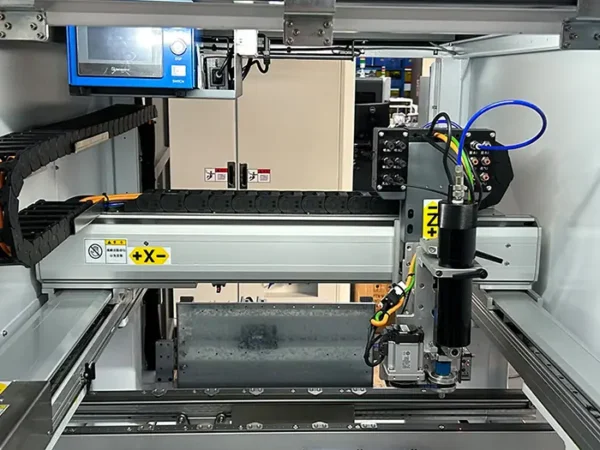

- Powerful vision positioning system, can meet the Mark point positioning, grasping edge positioning, 3D scanning positioning.

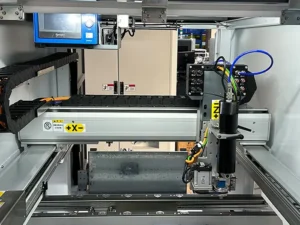

- Strong expandability, can extend the AOl inspection 3D inspection, UV exposure curing and other functions.

- Powerful platfom compatibility, contact and non-contactdispensing. single-head and multi-head synchronized dispensing, automatic

compensation and adjustment of the distance between the two heads. five-axis dispensing function basedon the needle A’R displacement, etc.

Product Process