Feature:

- The machine body and gantry are built with one-piece aluminum die-casting, strong structure, and stable operation.

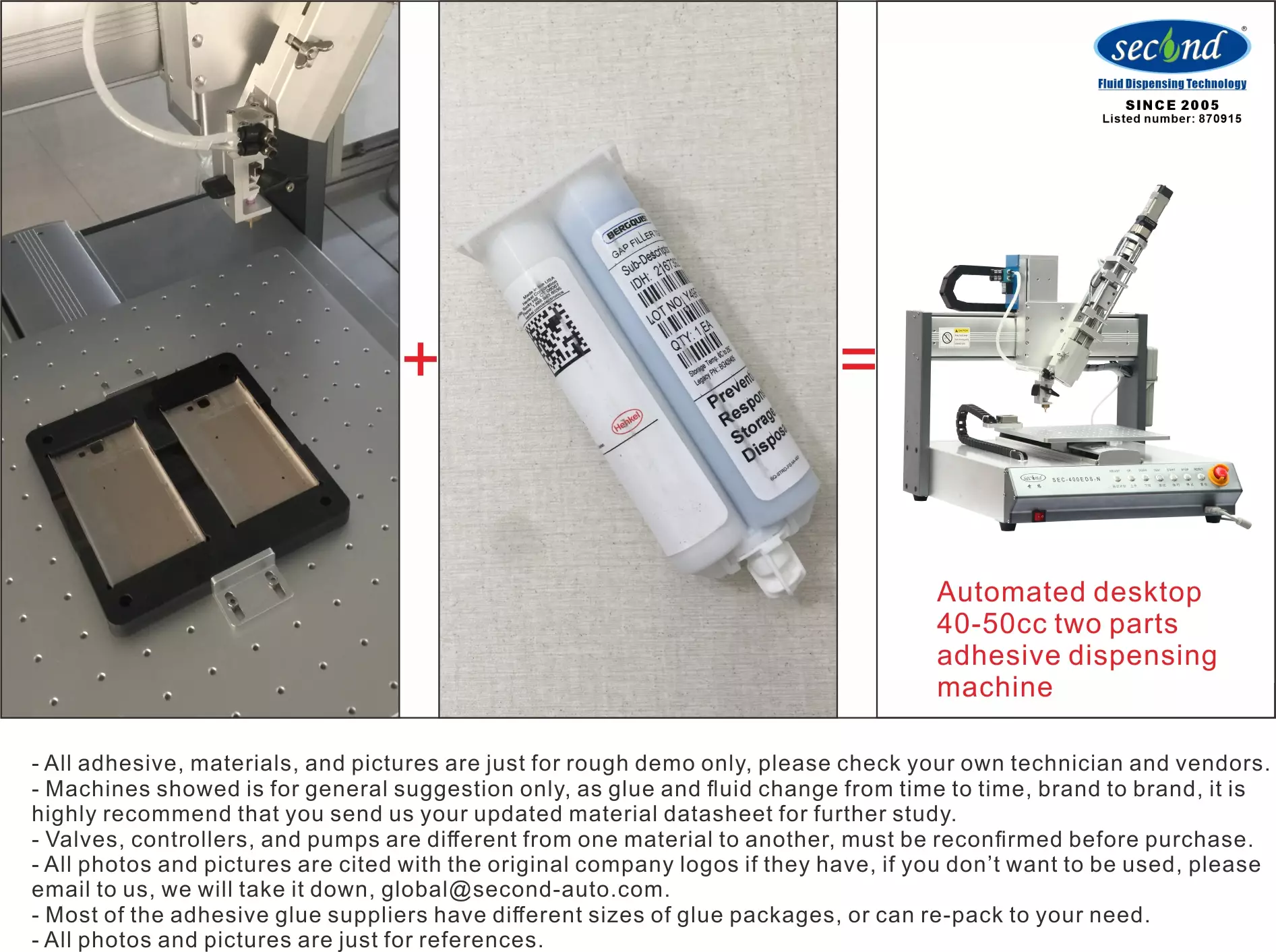

- Specially designed for high viscosity two-component materials’ automatic mixing and dispensing.

- It is a compacted body, but with larger dispensing strokes.

- It is using volumetric metering technology, this is able to extrude the AB materials out of the containers at a constant speed and with precise dose.

- With precision servo extrusion, the pressure is stable and the speed is uniform, which can effectively eliminate the influence of environmental pressure changes on the glue volume. And since the glue flow rate is faster and more stable, it is ensuring that the glue lines are uniform in thickness, and there is no phenomenon of large and small heads.

- The system also come with automatic anti-curing function, which effectively prevent the glue from clogging and blocking the nozzle.

- The two-part material cartridge can be customized according to the size of the adhesive glue packaged, such as 50ml, 250ml, 490ml. And also in two-component base on the different ratio.

- The dispensing system can chose to work with smart-controller, which can display the current data of dispensing torque, pressure level, automatic speed-switching, and remaining material-level in real time.

- It can also add material cooling system to delay the curing time for easy production.

- Applicable glue: suitable for 50ml 1:1, 2:1, 4:1, 5:1, 10:1, etc., 250ml10:1, 400ml1:1, 400ml2:1, 490ml10:1 and other double-liquid structural glue. We can also provide customize.

Material

This desktop dispenser setup is suitable for hot-melt, solide glue and similar adhesive material automatic dispensing purpose. Please feel free to send your MPP information; Material, Product, Production details and requirement to us, our engineers will provide free evaluation and solution.

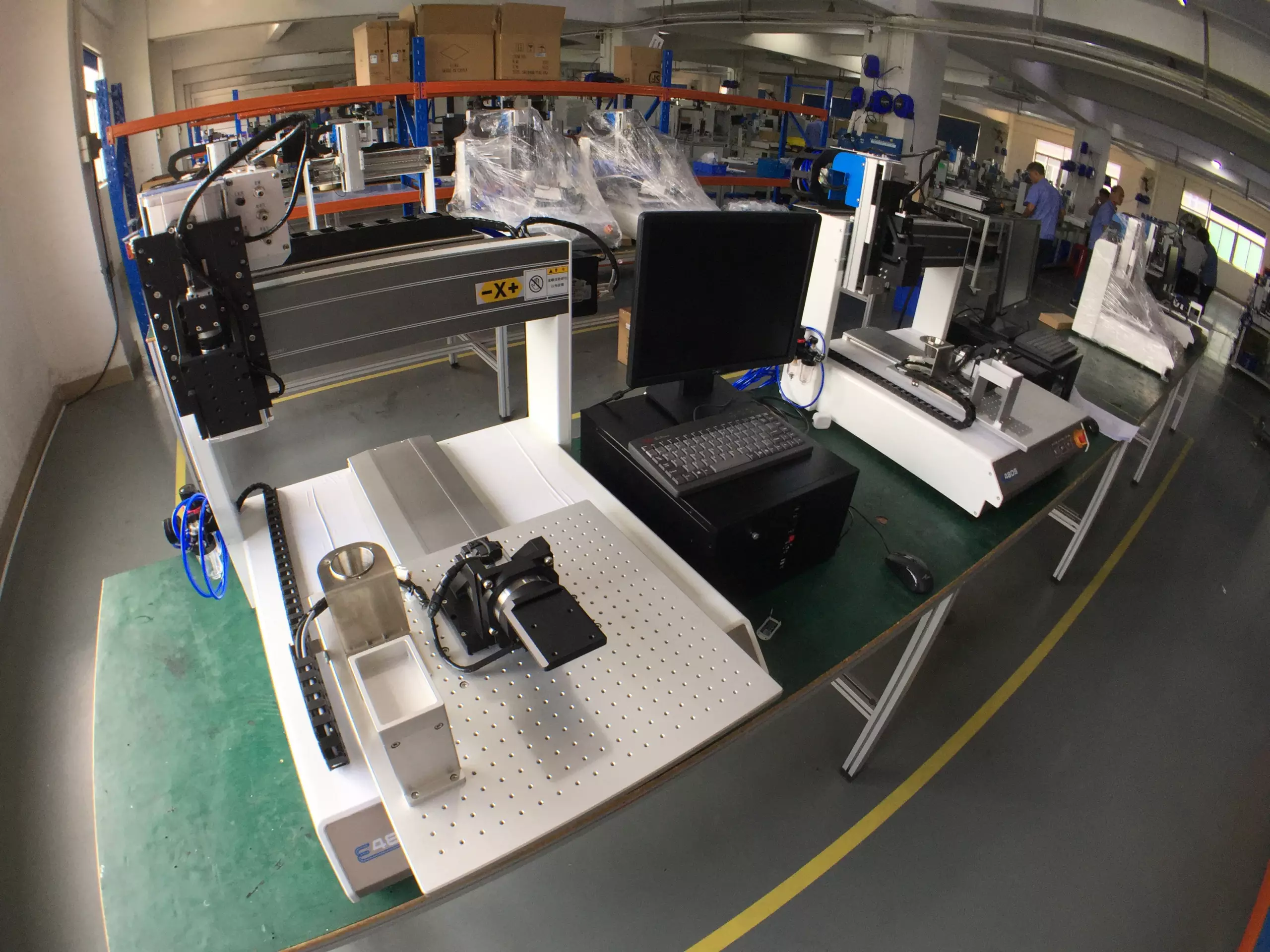

MANUFACTURING

Although the desktop industrial glue dispenser seems to have only XYZ axis, it seems to just has a simple structure, but professional production lines, such as EMS manufacturing factories are generally require very precise, some are up-to nanometer. A professional industrial desktop dispenser may has to travel back and forth for several kilometers and dispense thousands of times, so do not underestimate the quality requirements of a desktop dispensing robot. We provide professional, heavy-duty automatic dispensing machines. “Dispensing is no small matter, our quality starts from the desktop.

Available in stock

Most models of our desktop / benchtop dispensing machines are available in stock for fast delivery, between 10-15 days, we accept URGENT order in case if needed. In an average month, we stock-up about 100 units of standard sizes of the machines. Please contact us now to discuss and arrange.

CASE

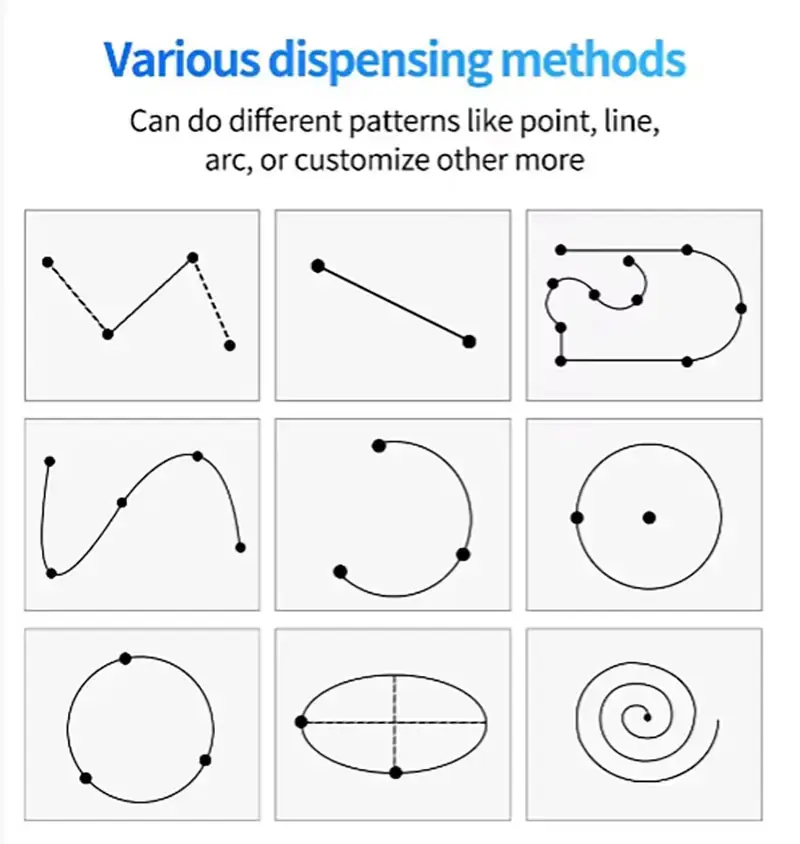

Dispensing process:

Multi-valve picture display

Applications:

PCB electronic parts fixing and protection, mobile phone, notebook case bonding, keyboard dispensing, LCD glass substrate, LED dispensing, optical lens dispensing, chip bonding, hardware parts bonding, electric toothbrush dispensing, etc.

Industry Applications: