Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

Dispensing technology is widely used in the consumer electronics industry, primarily for key processes such as bonding, sealing, thermal conductivity, electrical conductivity, protection, and encapsulation. Here are some typical application scenarios:

1. Structural Bonding and Fixing: Bonding of mid-frames in mobile phone/tablet assembly, fixing of camera modules, fingerprint recognition modules, side buttons, battery bonding, speakers/earpieces, laptops/smartwatches, etc.

2. Sealing and Waterproofing: Waterproofing of electronic devices, sealing and moisture protection for outdoor electronic products such as action cameras and smart speakers.

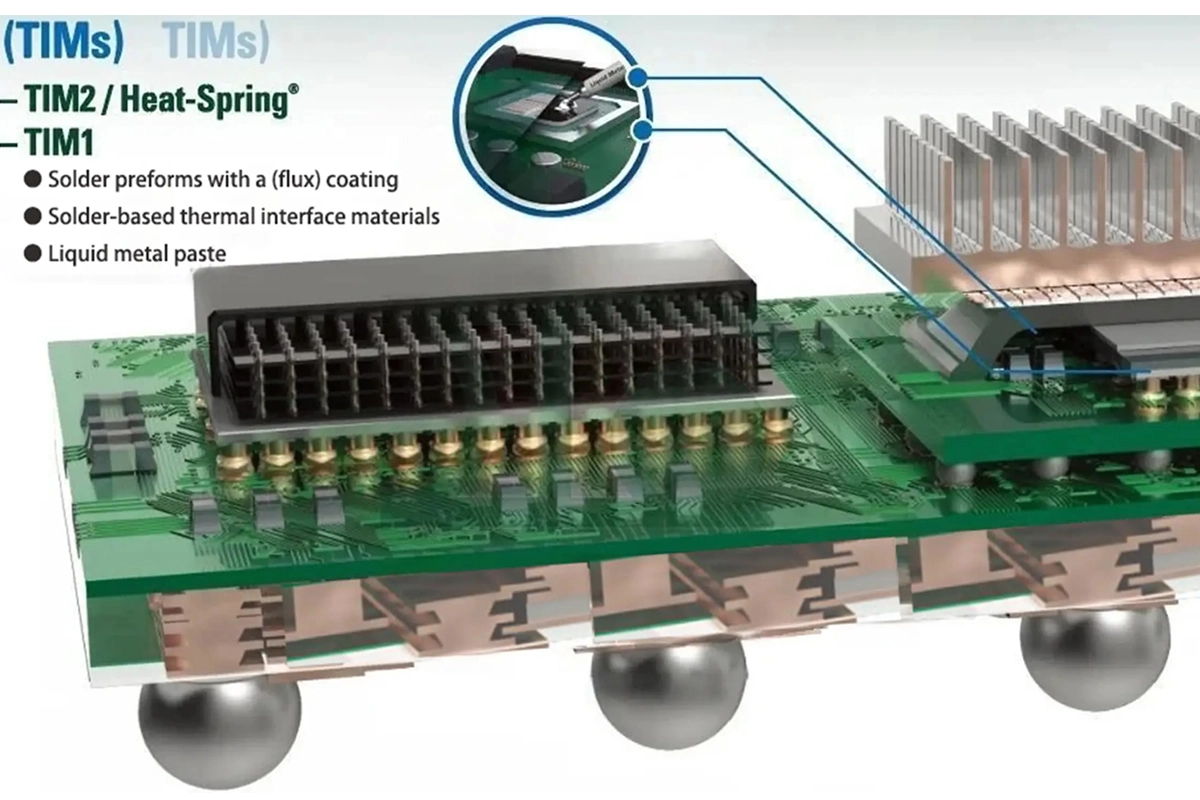

3. Thermal Conductivity and Dissipation: Chip heat dissipation. Applying thermal grease or thermal gel between heat-generating chips such as CPUs and GPUs and heat sinks to improve heat dissipation efficiency; 5G devices/routers.

4. Conductive Connection: Electromagnetic shielding (EMI shielding), antenna/sensor connections.

5. Component Protection: Chip Packaging (Underfill)、Circuit Board Conformal Coating、Coil Fixing

Automatic feeding by platen pump + Glue processing in transit tanks

+ piston pump for metering + Dispensing Valve

The lithium battery cell coating process is a precise and continuous core manufacturing process. Its core lies in coating the positive and negative electrode slurries of the battery onto the metal foil current collector with extremely high consistency and a preset thickness through precise methods such as slit extrusion. The coating is then immediately placed into a segmented temperature-controlled oven for drying to cure the coating and evaporate the solvent. The entire process ensures that the areal density, blank size and surface quality of the electrode sheet are uniform and stable through fully automatic tension control, online real-time thickness measurement and defect detection, thereby preparing a reliable and defect-free electrode substrate for subsequent processes.

RTV effectively suppresses the movement of plug-in components.

●Powerful spatial dispensing trajectory movement

●Mineral casting platform, with higher precision and greater stability

●Powerful expansion function to further realize multi-directional andmulti-angle dispensing process

●The platfomm and X/Y module base are made of mineral casting, and the

key surfaces are processed by grinding to ensure higher precision and

sta bi lity.

●Gantry type structure, withstand large loads, stable structure, and

●Powerful vision positioning system, can meet the Mark point positioning.

grasping edge positioning, 3D scanning positioning.

●Strong expandability, can extend the AOl inspection 3D inspection, UV

exposure curing and other functions.

●Powerful platfomm compatibility, contact and non-contactdispensing.

single-head and multihead synchronized dispensing, automatic compensation and adjustment of the distance between the two heads,five-axis dispensing function basedon the needle Ay’R displace ment, etc.

Module features:

● Higher precision and stability: the platform and X/Y module holders are

made of mineral casting; the key parts are processed by grinding;

● The platform in/out structure is more convenient for product pick and

place operation;

● Higher stability: the independent structure of X and Y axes can minimize

the movement inertia of the robotic arm.

● Multi-functional dispensing system with powerful industrial PC platform

compatible with six-axis dispensing + auxiliary detection.

Module features :

● Adoption of high-precision servo motor + grinding ball

screws

● E series vision dispensing platform has more advanced and

powerful functions, can be equipped with vision positioning,

● automatic calibration, dispensing detection, laser height

measurement and compensation, product information scanning,

MES system docking and other functions, to meet a variety of

industries and multi-scenario use.

Do not hesitate to contact us for further information, thanks in advance for your support!