Feature:

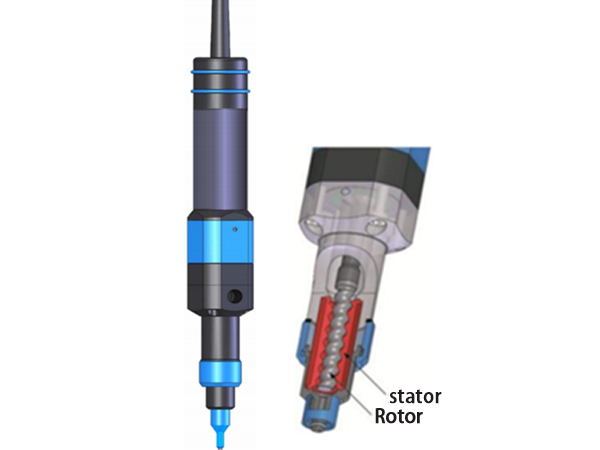

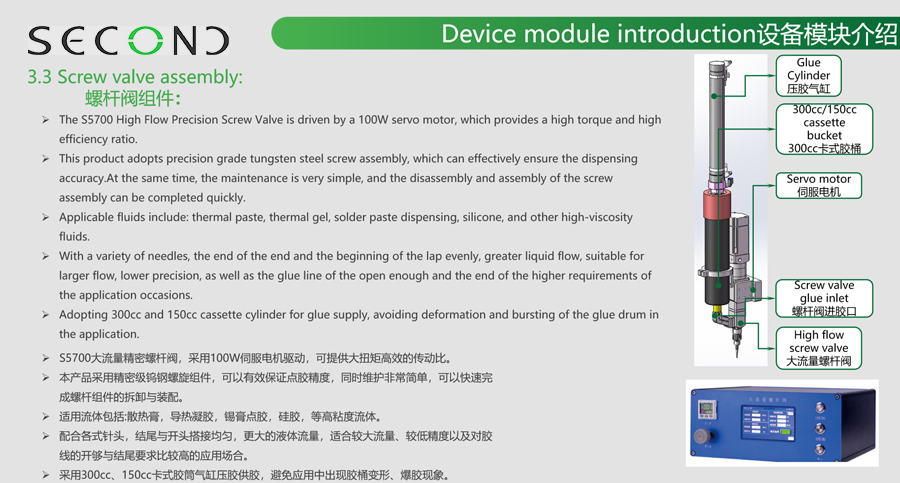

●The S5700 High Flow Precision Screw Valve is driven by a 100W servo motor, which provides a high torque and high efficiency ratio.

●This product adopts precision grade tungsten steel screw assembly, which can effectively ensure the dispensing accuracy.At the same time, the maintenance is very simple, and the disassembly and assembly of the screw assembly can be completed quickly.

●The product is widely used in: STM industry, optoelectronic industry, 3C digital products industry, connector industry, optoelectronic industry and so on.

●Applicable fluids include: thermal paste, thermal gel, solder paste dispensing, silicone, and other high-viscosity fluids.

●With a large flow Ruhr two-way valve, rotary switch, end and beginning of the lap evenly, greater fluid flow, suitable for larger flow, lower precision and the glue line of the open enough and the end of the higher requirements of the application occasions.

● Adopting 300cc cassette cylinder for glue supply, avoiding deformation and bursting of the glue drum in the application.

Device module introduction:

Function specifiction

Commonly Used Glue

Advantages:

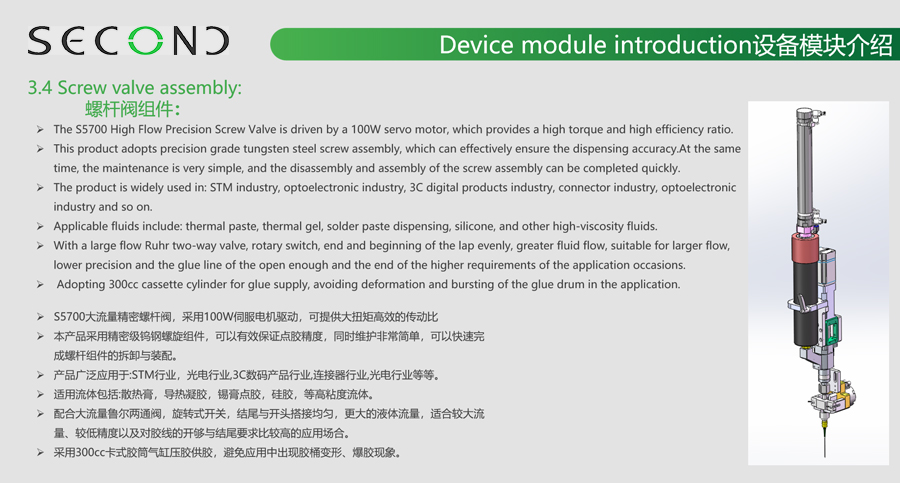

●The S5700 High Flow Precision Screw Valve is driven by a 100W servo motor, which provides a high torque and high efficiency ratio.

●This product adopts precision grade tungsten steel screw assembly, which can effectively ensure the dispensing accuracy.At the same time, the maintenance is very simple, and the disassembly and assembly of the screw assembly can be completed quickly.

●Applicable fluids include: thermal paste, thermal gel, solder paste dispensing, silicone, and other high-viscosity fluids.

●With a large flow Ruhr two-way valve, rotary switch, end and beginning of the lap evenly, greater fluid flow, suitable for larger flow, lower precision and the glue line of the open enough and the end of the higher requirements of the application occasions.

● Adopting 300cc cassette cylinder for glue supply, avoiding deformation and bursting of the glue drum in the application.

APPLICATIONS

SOLUTION

Material

Two parts silicone, resin, epoxy, polyurethean and other fluids with big tanks or barrels of materials.

This machine is designed and built for the two components (2 parts) materials that need to be mixing together base on the ratio automatically. The machine equips with CNC automatic dispensing robot, which able to perform automatic dispensing efficiently and effectively without operator. The system comes with two tanks (15, 30, or 70 liters as the standard, option for custmization).

Control

- The machine is user friendly, and operating by Window base software.

- The software is design and developed by Second Intelligent.

- With over 15 years in dispensing and potting, the software has included all of the functions that meets dispensing and potting needs. And it has been fine tuned and debugged well to provide good quality output.

- The software has English instruction, and we welcome your language as well.

- It is absolutely user friendly. With this computer system, it comes with an internet remote control access function, this allow us to help operator to conduct troubleshooting of the software, and can be used as an online instruction as well. It is welcomed, easy and helpful for international service and support.

-1200x208-1.webp)