Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

Adopt high-speed, high-precision modules, automatic visual alignment, and assemble MEA/bipolar plates

Adopt multi-speed servo stacking, real-time force feedback, combined with high-precision, high-rigidity carriers, so that the stack is stable and deformed

Full functions, including airtight test, insulation test, CVM assembly, stack shell assembly, laser marking, intelligent offline and other functions

Scientific and strict airtight pipeline design, flow method/pressure difference method, support zero leakage and standard leakage test

Modular design of production line, with high flexibility and informationization capabilities

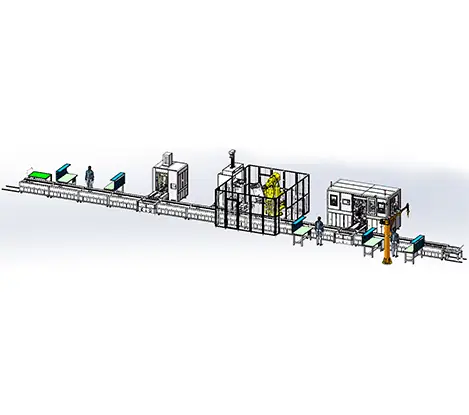

Main process

The production line has high-speed automatic stacking, servo stacking, manual screw locking, airtight insulation test, CVM/shell installation, laser marking, screw locking and other functions, with complete functions, scientific and rigorous process, information production, high stability and other capabilities.

Tooling online→ Manual placement of lower end plates,current collectors special plates and MEA→ Tooling online→ Manual placement of special plates,MEA. current collectors,and upper end plates→ Automatic stacking →Manual locking screw → Air tightness test → Manually install CVM components→ Insulation testing→ Housing assembly→ Laser marking→ Smart offline

RTV effectively suppresses the movement of plug-in components.

●The production line is modular and modular in design, and the corresponding machines can be added or deleted according to the process requirements and production capacity needs;

●When a single process of the production line is repaired or replaced, it will not affect the production of other processes of the entire line;

●A single process can run independently to prepare samples;

Accurate ratio, integrated glue mixing and filling,

to achieve truly fully automated mixing, avoid manual mismatching,

resulting in waste and scrap. Accurate positioning,

fast speed, simple and convenient adjustment, strong versatility, conventional LED, electronic appliances,

handicrafts can be used. Simple programming, simple operation,

can be used with assembly lines,

anyone can operate the counting function, non-standard mode,

bottom glue mode, liquid level alarm

① The production line is modular and modular in design, and the corresponding machines can be added or deleted according to the process requirements and production capacity needs;

② When a single process of the production line is repaired or replaced, it will not affect the production of other processes of the entire line;

③ A single process can run independently to prepare samples;

Do not hesitate to contact us for further information, thanks in advance for your support!