Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

Accept production capacity customization and different process combinations.

Coil cutting system, realize 3CCM, frame, GDL and other coil or sheet cutting and waste recycling.

Coil-to-sheet peeling system, realize the peeling and unloading of sheet materials on coils.

Visual positioning system, visual positioning for lamination and dispensing.

Five-in-one lamination system, realize accurate lamination and pre-pressing of frame + 3CCM + frame.

Seven-in-one packaging system, complete GDL + 5CCM + GDL dispensing packaging molding, pressure holding, cutting, testing, etc.

Information management system, can realize the transmission and automatic storage of process data such as bad position reading, temperature, pressure, dispensing speed, defect position, leakage value, capacity, etc., compatible with MES system, and support one-click backup.

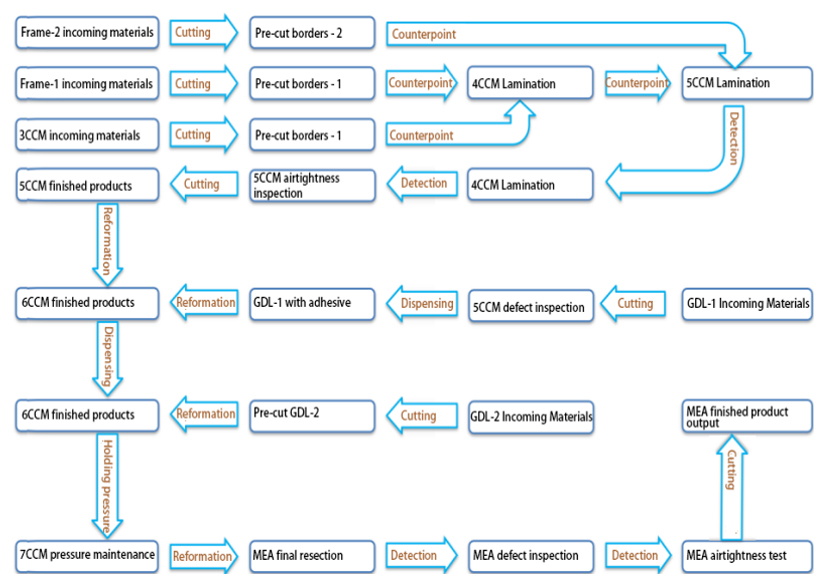

Main process

Realize the full process production of hydrogen fuel cell membrane electrode

Frame-2 incoming materials→Cutting→Pre-cut borders-2→ Counterpoint→ 5CCM Lamination→ Detection

→ 4CCM Lamination→ Detection→ 5CCM airtightness insoection→ Cutting→ 5CCM finished products

→ 6CCM finished products→ 6CCM finished products→ 7CCM finished products→ Reformation

→ Mea final resection→ Detection→ Mea detect inspection→ Detection→ MEA airtightness test

→ MEA finished product output

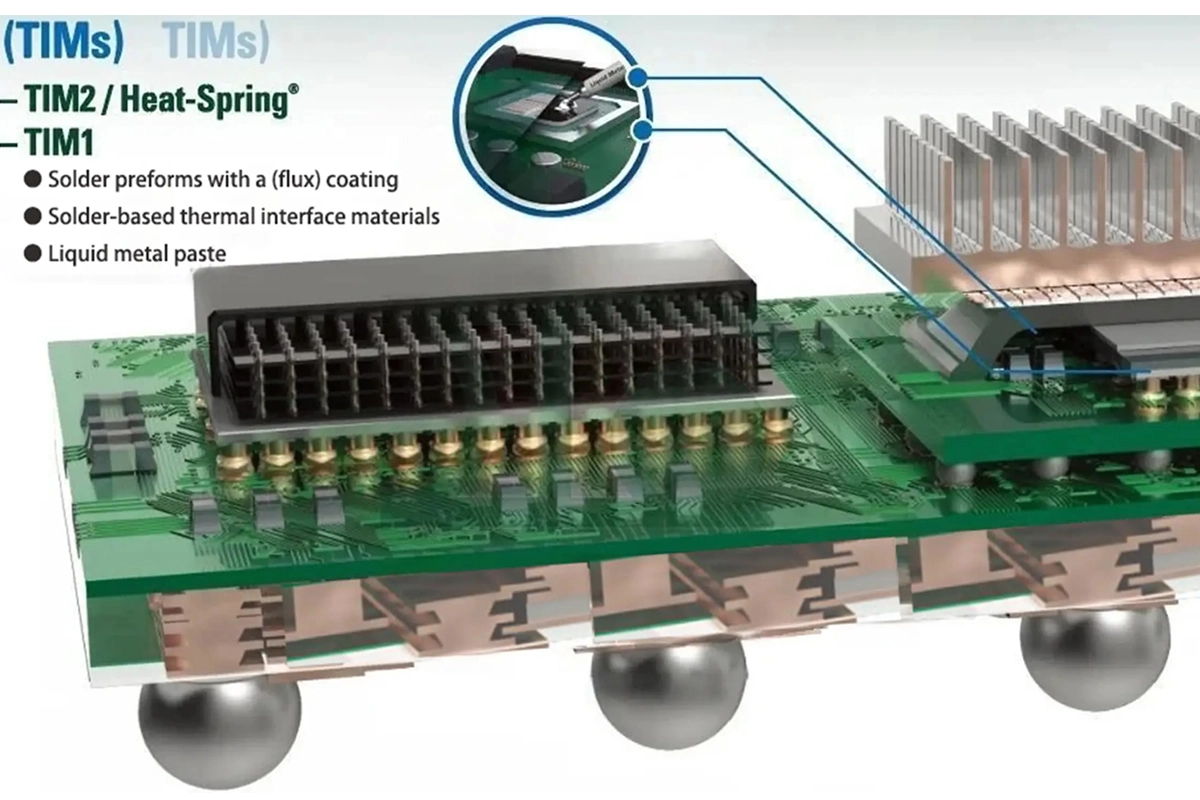

RTV effectively suppresses the movement of plug-in components.

●The production line is modular and modular in design, and the corresponding machines can be added or deleted according to the process requirements and production capacity needs;

●When a single process of the production line is repaired or replaced, it will not affect the production of other processes of the entire line;

●A single process can run independently to prepare samples;

① The production line is modular and modular in design, and the corresponding machines can be added or deleted according to the process requirements and production capacity needs;

② When a single process of the production line is repaired or replaced, it will not affect the production of other processes of the entire line;

③ A single process can run independently to prepare samples;

Do not hesitate to contact us for further information, thanks in advance for your support!