Feature:

IPC + Second intelligent motion control card integrated withadvanced algorithms, together with high-precision three-axis manipulator, realizes three-dimensional high-speed and precisemovement.

Second intelligent customized high-precision micro-piston pump, small amount of glue and high precision.

Through precise control of the metering motor, it can achieve precise proportioning, automatic mixing and automatic potting of two-component glue.

With vacuum feeding, vacuum degassing, optional heating, stirring,automatic cleaning, pressure monitoring and other functions, can cope with a variety of complex glue environment.

Unique industrial design, generous appearance, compact structure,genuine windows system, stable machine, friendly operation interface, cost-effective

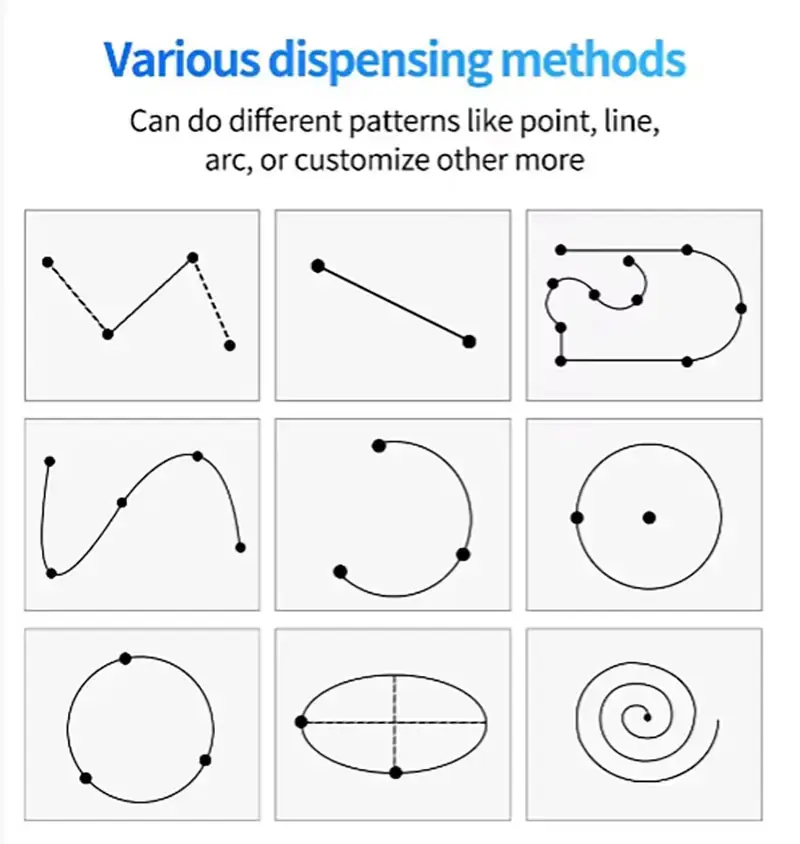

Dispensing process:

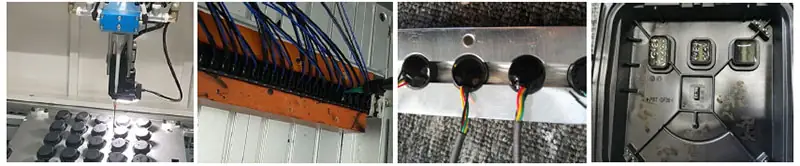

Multi-valve picture display

Application

Suitable for two-component micro-automatic potting, PCB board industry, electronic

component industry, electric light source industry, small household appliance industry,

ignition industry, automotive supply industry, vacuum cleaner industry, filter industry and

many other fields

Micro potting machine/SEC-S400-BH/SEC-S500-BH

• High-speed and stable three-axis motion platform

• Micro potting, high precision

• Rich configurations and wide application

Industry Applications:

Suitable for various needs in the dispensing industry: common glues such as UV glue,red glue,silver glue,ABglue,COB black glue,conductive glue,Epoxy Resin,Silicones,heat dissipation aluminum paste,instant glue,etc

SOLUTION

Material

Two parts silicone, resin, epoxy, polyurethean and other fluids with big tanks or barrels of materials.

This machine is designed and built for the two components (2 parts) materials that need to be mixing together base on the ratio automatically. The machine equips with CNC automatic dispensing robot, which able to perform automatic dispensing efficiently and effectively without operator. The system comes with two tanks (15, 30, or 70 liters as the standard, option for custmization).

Control

1. The machine is user friendly, and operating by Window base software.

2.The software is design and developed by Second Intelligent.

3.With over 15 years in dispensing and potting, the software has included all of the functions that meets dispensing and potting needs. And it has been fine tuned and debugged well to provide good quality output.

4.The software has English instruction, and we welcome your language as well.

5.It is absolutely user friendly. With this computer system, it comes with an internet remote control access function, this allow us to help operator to conduct troubleshooting of the software, and can be used as an online instruction as well. It is welcomed, easy and helpful for international service and support.