Application cases:

Needle glue dispensing Valve can be applied to the following fields:

- Automation

- Electronics

- Mechanical engineering

- Automotive electronics

- Medical

- Pharmaceuticals

- Information technology

- Consumer electronics

Glue and craft:

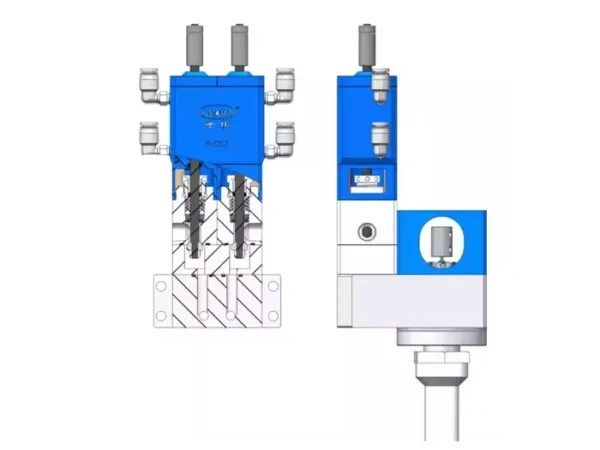

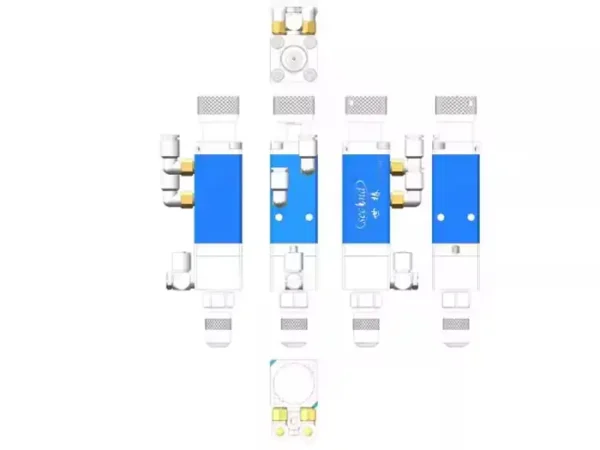

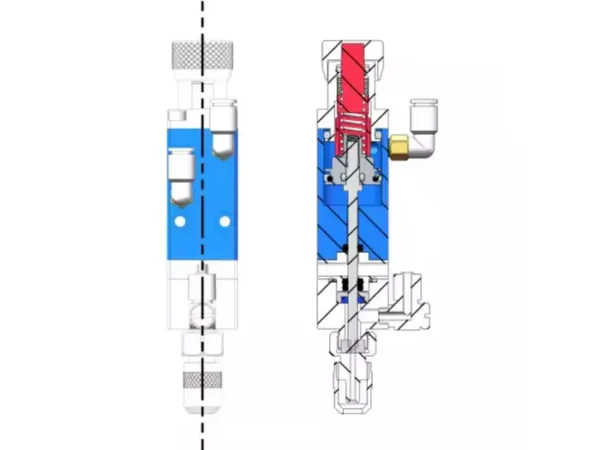

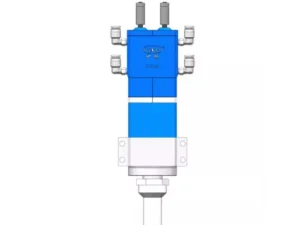

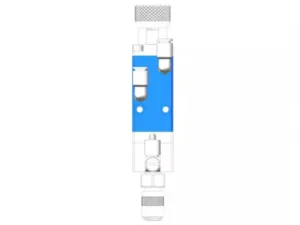

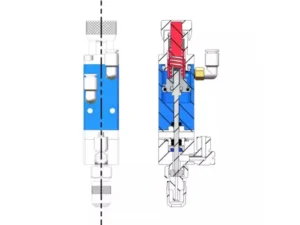

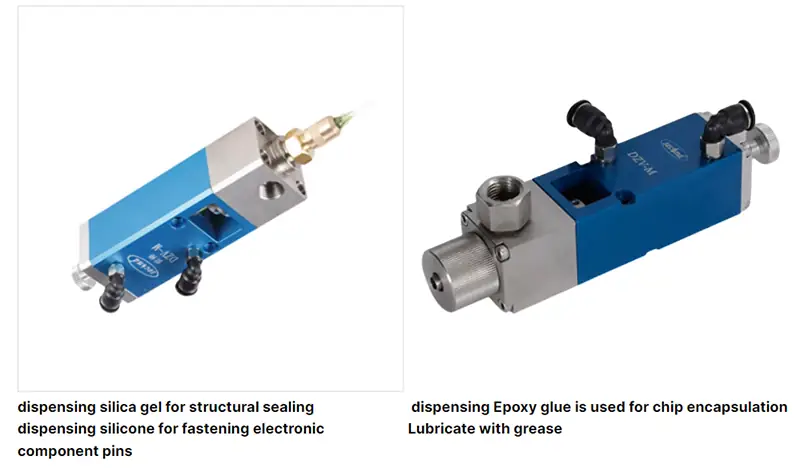

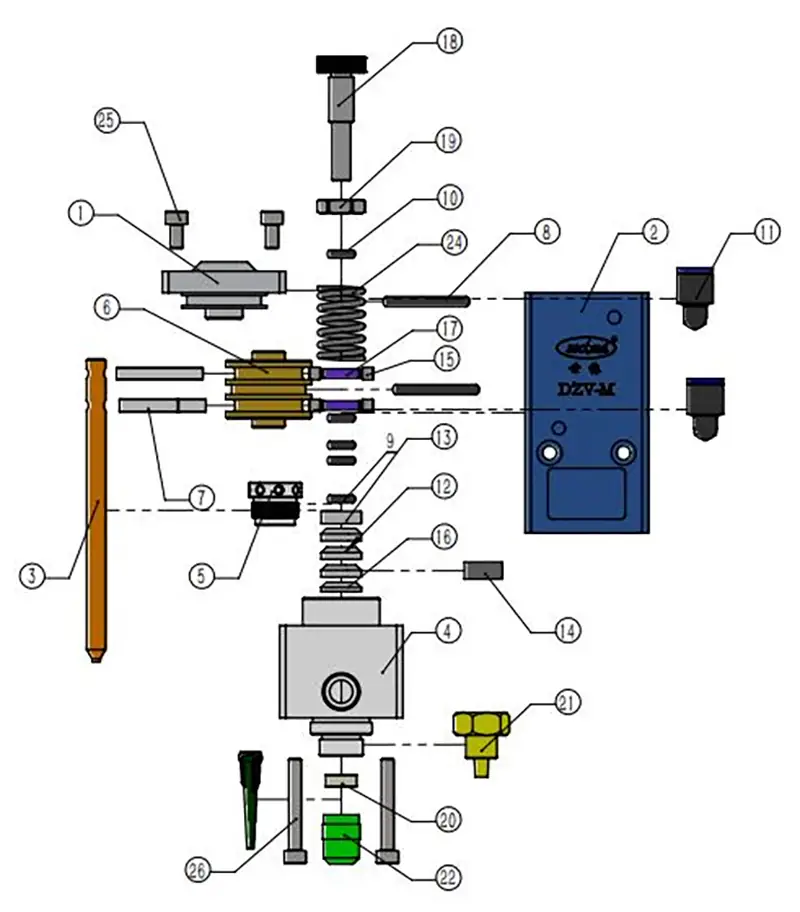

F-Z101 Needle glue dispensing Valve uses the most advanced micro dispensing technology to achieve extremely high precision dispensing, especially suitable for high viscosity and ultra-high viscosity media. The system can be widely used in a variety of different liquids,such as:

- SMT adhesive

- Filled conductive adhesive

- Conductive silver glue

- Solder paste

- Flux

- Silicone

- LED phosphor

- Bottom filler

- Hot melt adhesive

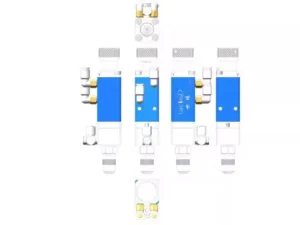

APPLICATIONS

SOLUTION

Material

Two parts silicone, resin, epoxy, polyurethean and other fluids with big tanks or barrels of materials.

This machine is designed and built for the two components (2 parts) materials that need to be mixing together base on the ratio automatically. The machine equips with CNC automatic dispensing robot, which able to perform automatic dispensing efficiently and effectively without operator. The system comes with two tanks (15, 30, or 70 liters as the standard, option for custmization).

Control

- The machine is user friendly, and operating by Window base software.

- The software is design and developed by Second Intelligent.

- With over 15 years in dispensing and potting, the software has included all of the functions that meets dispensing and potting needs. And it has been fine tuned and debugged well to provide good quality output.

- The software has English instruction, and we welcome your language as well.

- It is absolutely user friendly. With this computer system, it comes with an internet remote control access function, this allow us to help operator to conduct troubleshooting of the software, and can be used as an online instruction as well. It is welcomed, easy and helpful for international service and support.

-1200x208-1.webp)