Feature:

● Proven SECOND motor allows for compact and lightweight design

● Longer product lifecycle due to diamond-like carbon coating and improved rid and piston designs

● Simple and user-friendly control panel

Typical Fluids Handled:

● Thermal Interface Materials

● Silicon

● Colorants

● Grease

● Ink

● Adhesives

Product Description

Second 55-gallon High-precision High-efficiency Plunger-type Pressure Plate Pump Is Suitable for High-viscosity Glue

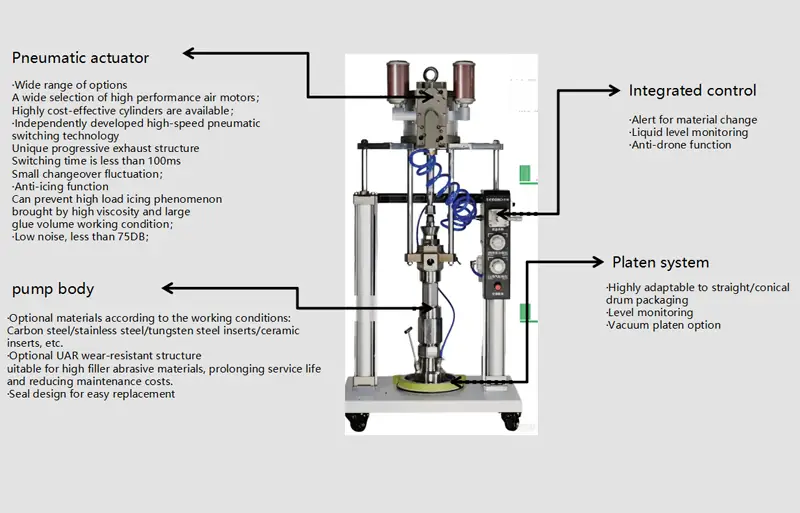

Functional features:

Suitable for pumping high-filler and high-viscosity glue

● Provide high output pressure

With pneumatic motor, pressure output ratio is 43:1;

(Example: According to the factory standard air pressure of 0.6Mpa, it can provide 25.8Mpa glue supply pressure)

● Provide large displacement: one circulation pump can deliver 170CC of fluid

● Has excellent wear resistance

a. The plunger rod is made of specially treated carbon steel or ceramic material;

b. The key structure that withstands impact and abrasion is nested with tungsten steel;

● Unique sealing structure design and the use of special sealing materials;

The above characteristics can greatly extend the life of the seal

● Easy installation and maintenance

The plunger rod and seal are easy to replace; Optional maintenance kit;

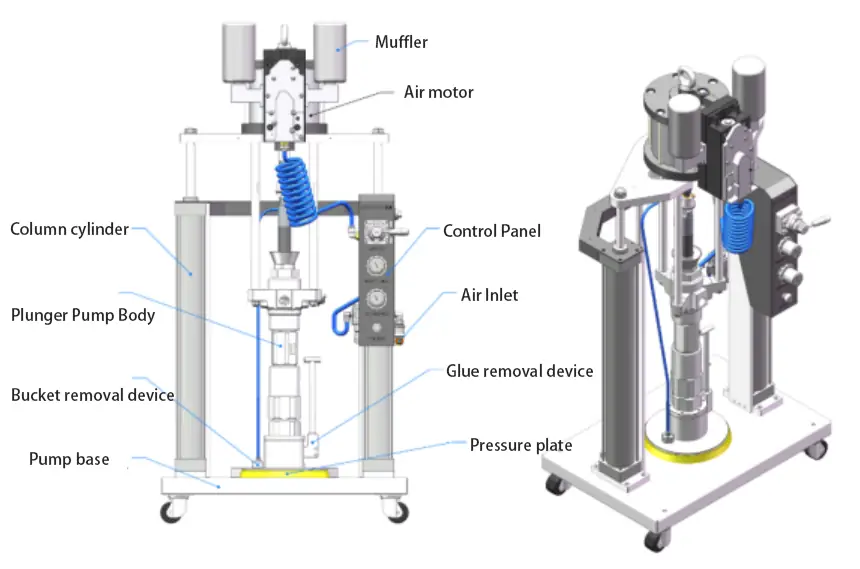

Structural layout instroduction

Structure diagram

Commonly Used Glue

Plunger Platen Pump Selection Chart

Item | Parameter |

Glue Package | 5 Gallon | 55 Gallon |

Model | B-Z301 | B-Z402 | B-Z601 | B-Z602 |

Drive method | Air Cylinder | Air Motor | Air Motor |

Pump Body Support | Double Column Cylinder | Double Column Cylinder |

Pump Body Type | Carbon Steel Pump | Wear Resistant Pump | Carbon Steel Pump | Wear Resistant Pump |

Applicable Glue Viscosity | 50000-1000000 CPS |

Bucket inner diameter size | 284~288mm | 564~589mm |

Glue Discharge | 170CC/cycle |

Booster Ratio | 43:1 |

Maximum Pump Speed | 30 Cycle/min |

Fluid Output Pressure | ≤28Mpa |

Pump Body Operating Temperature | <80℃ |

Item | Parameter |

Model | B-Z301 | B-Z402 | B-Z601 | B-Z602 |

Displacement Rod Material | Stainless Steel | Ceramic | Stainless Steel | Ceramic |

Piston Cylinder Material | Stainless Steel | Ceramic | Stainless Steel | Ceramic |

Pressure Plate Seal Material | Fluoroelastomer |

Cutting Valve Material | Carbon Steel | Tungsten Steel | Carbon Steel | Tungsten Steel |

Operating Air Pressure | 0.2~0.7Mpa |

Glue Discharge Thread Specification | NPT1 |

Mode of Operation | Pneumatic+Electric | Control Pneumatic |

Equipment Dimensions | 750*500*1535 | 750*500*1535 | 1220*770*1669 | 1220*770*1669 |

(L*W*H)mm | (L*W*H)mm | (L*W*H)mm | (L*W*H)mm |

Gross Equipment Weight | Approx.220kg | Approx.220kg | Approx.320kg | Approx.320kg |

Wear Resistant Pumps Available as Option | ✔ | / | ✔ | / |

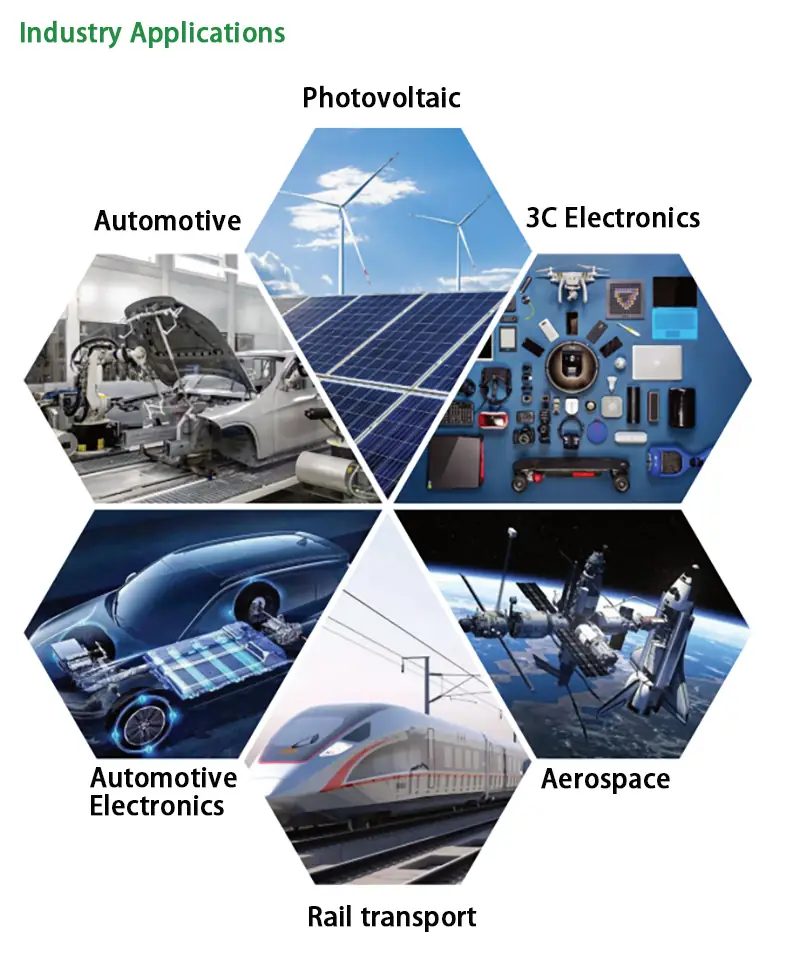

Industrial Applications:

Typical Markets:

● Automotive Electronics

● Telecommunication Electronics

● Consumer Electronics

Its application areas include:

● Photovoltaic

● Automotive

● 3C Electronics,

● Automotive Electronics

● Aerospace

● Rail transport

-1200x208-1.webp)