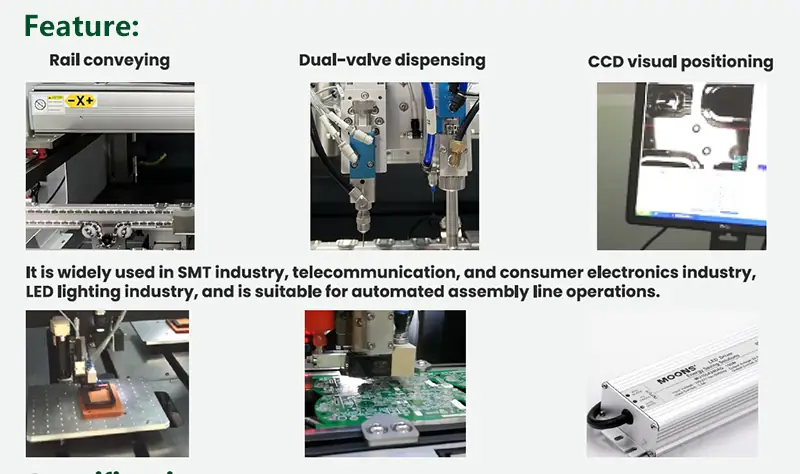

Feature:

- High stability:

Marble integrated platform, stable equipment structure. First-line brand components are selected, with fewer vulnerable parts and fewer faults. - Flexibility:

The automatic width adjustment of the track can adapt to dispensing products of different sizes.

The needle head can be tilted and rotated, automatically aligned, automatically measured in height, automatically weighed, automatically wiped, and dual valve synchronous/asynchronous, etc., which can be flexibly equipped with various functional modules to meet various dispensing processes and achieve high-precision dispensing.

PRODUCT DETAILS

DISPENSING PROCESS

Commonly used glue

Multi-valve picture display

Benefits:

Improve productivity:

Automatic assembly line operation, reduce manual intervention, and improve utilization rate.

It can operate on two tracks, reduce waiting time and improve production efficiency. Dual-track operation can also meet the dispensing of two products at the same time.

Expandability:

It can be configured with a scanning system, connected to the MES system, realize big data interaction, and improve the level of workshop information management.

Application range:

It is widely used in SMT industry, 3C electronics industry, LED lighting industry, and is suitable for automated assembly line operation.

SOLUTION

Material

Two parts silicone, resin, epoxy, polyurethean and other fluids with big tanks or barrels of materials.

This machine is designed and built for the two components (2 parts) materials that need to be mixing together base on the ratio automatically. The machine equips with CNC automatic dispensing robot, which able to perform automatic dispensing efficiently and effectively without operator. The system comes with two tanks (15, 30, or 70 liters as the standard, option for custmization).

Control

- The machine is user friendly, and operating by Window base software.

- The software is design and developed by Second Intelligent.

- With over 15 years in dispensing and potting, the software has included all of the functions that meets dispensing and potting needs. And it has been fine tuned and debugged well to provide good quality output.

- The software has English instruction, and we welcome your language as well.

- It is absolutely user friendly. With this computer system, it comes with an internet remote control access function, this allow us to help operator to conduct troubleshooting of the software, and can be used as an online instruction as well. It is welcomed, easy and helpful for international service and support.

DISPENSING PROCESS