Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

VR Equipment Dispensing Application

Vr Equipment Dispensing Application Plays A Vital Role In The Manufacturing Process, And Is Mainly Used For The Bonding And Fixing Of The Following Key Components:

Infrared Filter Bonding: Use Acrylic Uv Adhesive Mx-3652 Series. This Adhesive Has The Characteristics Of High Viscosity, Toughness And Flexibility, Impact And Vibration Resistance, And Excellent Moisture Resistance. It Is Suitable For The Bonding And Fixing Of Most Materials, And Can Realize Automated Gluing Process.

Metal Parts Bonding: Use Pur Hot Melt Adhesive Mx-85 Series. This Adhesive Has Excellent Bonding Strength, Temperature Resistance, Chemical Corrosion Resistance And Aging Resistance, And Is Suitable For Faster Production Mode.

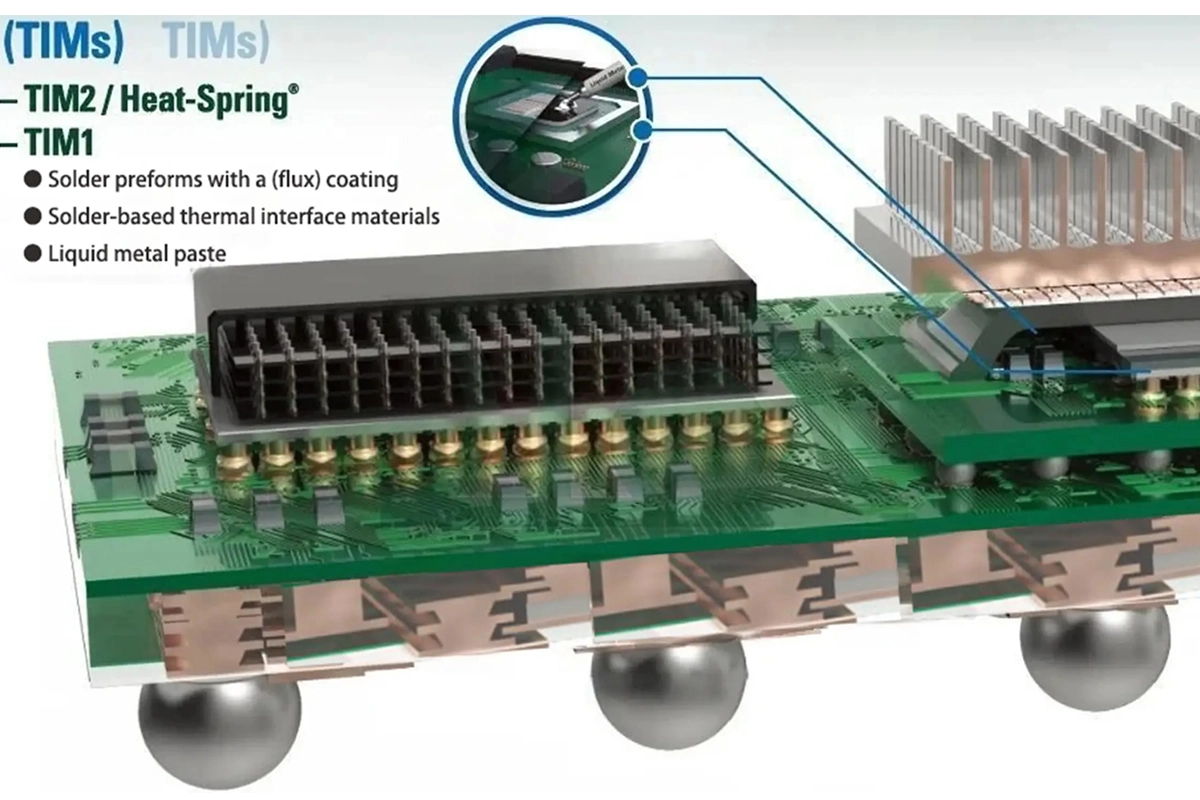

Pcb Three-Proof Coating: Use Polyurethane Three-Proof Adhesive Mx-2301. This Adhesive Has Low Odor, High Strength, Does Not Contain Harmful Solvents, Has

Visual positioning + laser height measurement + syringe dispensing

RTV effectively suppresses the movement of plug-in components.

●Six-axis mineral casting platforms for more powerful applications;

●Powerful functions ● Rich configuration ●Wide range of applications;

●Strong scalability ● stable performance ●Anti-dumbness

Multi-functional 5-axis dispensing platform with powerful motion controlsystem supports various standard curves, straight lines with arbitrary axes,spatial arcs, spatial spirals, spatial ellipses, spatial involutes, and spatialspline interpolation. It can be applied to the dispensing of round andshaped products.

The equipment is equipped with Mark point positioning and edge graspingpositioning functions, automatically calculates the center position of theproduct and corrects and compensates for the motion of each axis, and canautomatically identify the product omission and misplacementphenomenon.

Modular design and flexible matching to meet the contact and non-contactdispensing process, wider application.

Six axes and four linkage, suitable for VR/AR smart wearable products in the frame, skeleton continuous dispensing, lens dispensing, battery protection board dispensing, thermal paste dispensing, magnet bonding glue and other processes

Double Y rear platform alternating operation to further improve production efficiency

Powerful module carrying capability, compatible with a variety of glue types and packaging dispensing applications

Dual X/ Dual Y/ Dual Z workstation (dual station four stations), the two workstationscycle alternately, further improve the operational efficiency, but also to achieve thefront-end dispensing, back-end detection or curing, product deformation correctionor real-time 3D path guidance function. The workstation is also equipped with MESfunction, which can upload real-time information of equipment work and processinformation to MES system.

Do not hesitate to contact us for further information, thanks in advance for your support!