Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

Dispensing machines play a crucial role in the manufacturing, packaging, and assembly of semiconductor devices. Their application spans multiple key stages, directly impacting device performance, reliability, and integration. The following are the main application scenarios for dispensing machines in the semiconductor field:

1. Chip Packaging: Underfill, Die Attach, Encapsulation

2. Advanced Packaging: Fan-Out and Through-Silicon Vias (TSV), 3D Stacked Packaging

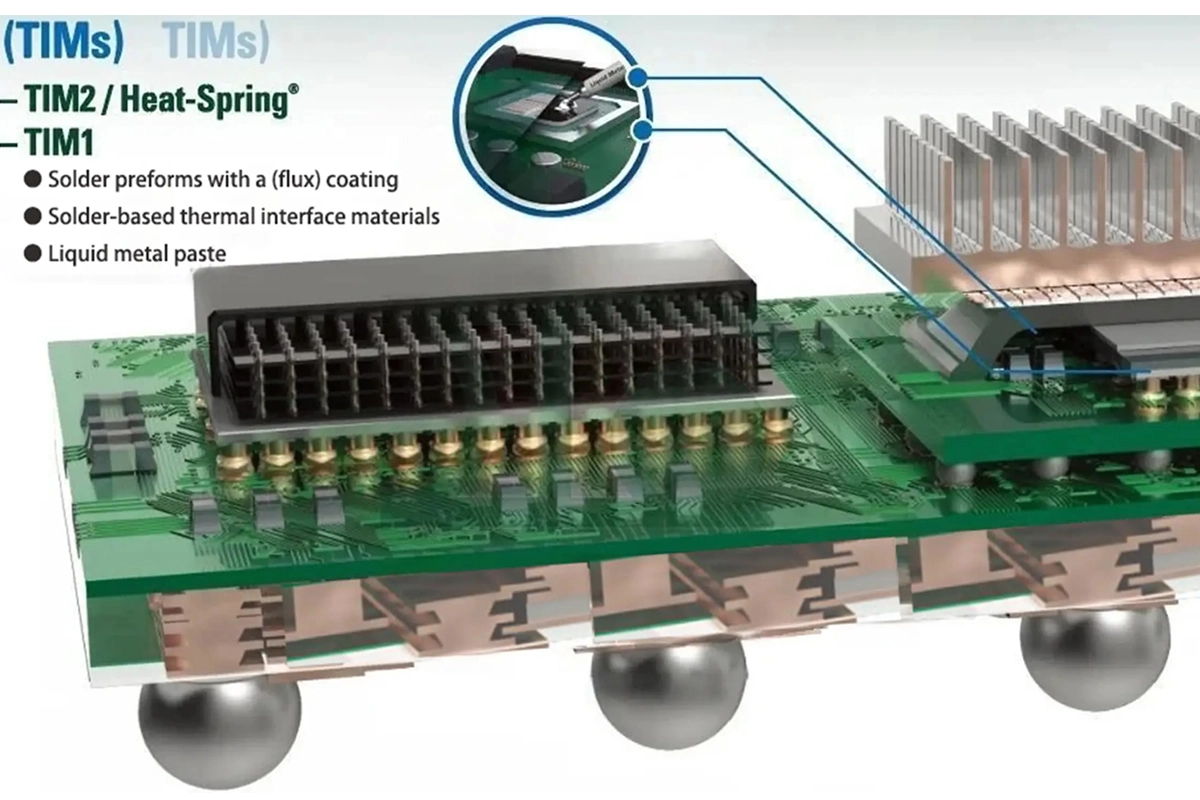

3. System-in-the-Box Assembly and SMT Processes: PCB-level dispensing, Thermal Insulation Material (TIM) coating

4. Sensors and MEMS Devices: Sealing and protection, Optical component bonding

5. Power Devices and Automotive Electronics: Insulation and heat dissipation, Potting

6. Military and Aerospace: High-reliability packaging, Electromagnetic Interference (EMI) immunity

Visual positioning + laser height measurement + syringe dispensing

RTV effectively suppresses the movement of plug-in components.

●One-piece mineral casting, ultra-high precision and ultra-stability;

●Powerful expansion capabilities for ion cleaning, dispensing, testing, UV exposure, etc;

●Extensible;

●Powerful feature ● Rich Configuration ● smart;

●Wide range of application

● The platfomm and X/Y module base are made of mineral casting, and the key surfaces are processed by grinding to ensure higher precision and stability.

● Gantry typestructure, withstand large loads, stable structure, and

● Powerful vision positioning system, can meet the Mark point positioning, grasping edge positioning, 3D scanning positioning.

● Strong expandability, can extend the AOl inspection 3D inspection, UV exposure curing and other functions.

● Powerful platfom compatibility, contact and non-contactdispensing. single-head and multi-head synchronized dispensing, automatic

compensation and adjustment of the distance between the two heads. five-axis dispensing function basedon the needle A’R displacement, etc.

The platform and X/Y module base are cast in mineral form, and the key surface is grinded to ensure higher accuracy and stability

Gantry type structure, bearing large load, stable structure

Powerful visual positioning system, can meet the Mark point positioning, grab edge positioning, 3D scanning positioning,

Strong scalability, can expand AOI detection 3D detection, UV exposure curing and other functions

Strong platform compatibility, contact and non-contact dispensing, to meet the dispensing operations of different products and processes

Replaceable stainless steel housing to achieve 100 levels of cleanliness

▪ Square welding frame + sheet metal shell, integrated steel plate on the table, all mounting surfaces are precision processed to ensure accuracy and better stability

▪ Cantilever structure is suitable for products with higher aspect ratio, which can better ensure the accuracy and stability of the robot arm while meeting the large stroke

▪ Powerful visual positioning system, which can meet the requirements of Mark positioning, edge positioning, 3D scanning positioning

▪ Strong scalability, can expand AOI detection 3D detection, UV Ricoh curing and other functions

▪ Strong platform compatibility, contact and non-contact dispensing, to meet the dispensing operations of different products and processes

Do not hesitate to contact us for further information, thanks in advance for your support!