Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

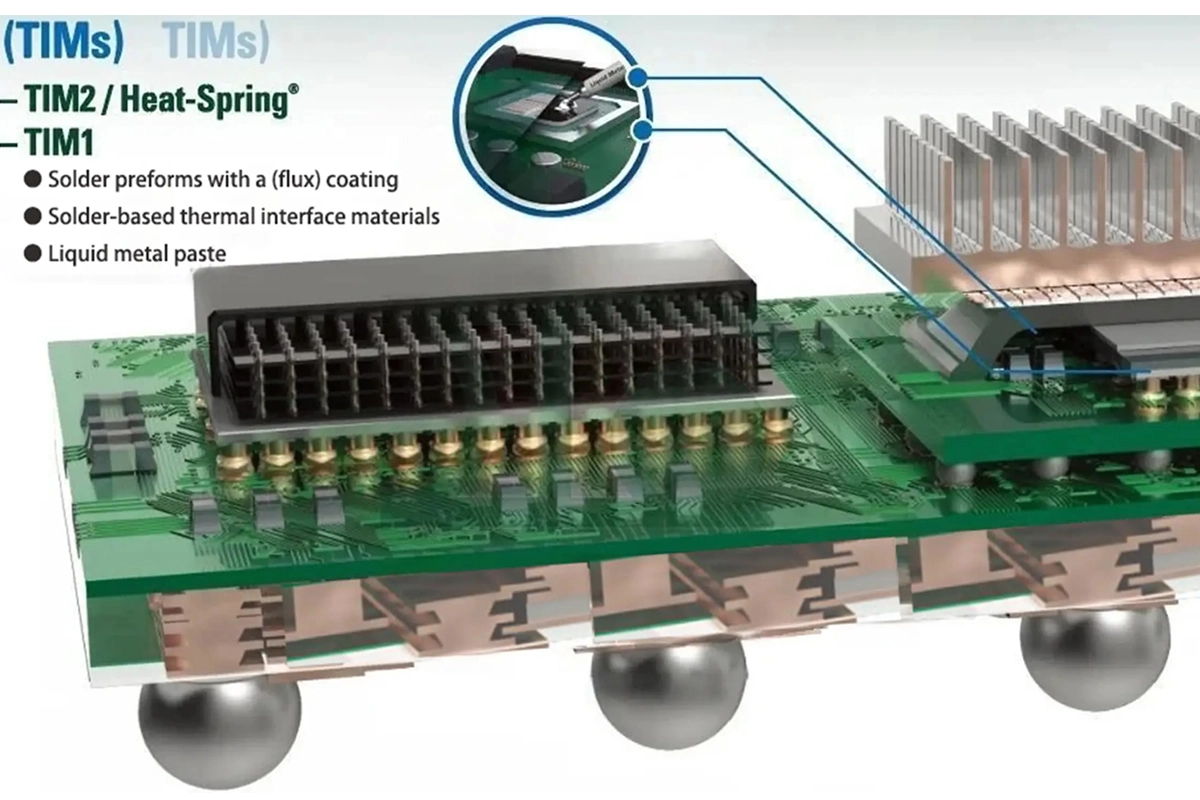

The application of vacuum potting machines in the IGBT (Insulated Gate Bipolar Transistor) industry mainly focuses on solving key problems such as air gaps and bubbles during the device packaging process, ensuring the long-term reliability and performance stability of IGBT modules. The main applications and advantages are as follows:

1. Bubble elimination and improved insulation reliability

2. High-precision filling and structural protection

3. Improved thermal conductivity and heat dissipation performance

4. Enhanced environmental resistance and durability

5. Automation and process consistency

Typical application cases: Automotive-grade IGBT modules, high-voltage frequency converters and photovoltaic inverters, rail transit traction systems

Summary: The core value of vacuum potting machines in the IGBT industry lies in directly improving the electrical insulation, thermal conductivity, mechanical strength, and environmental adaptability of modules by eliminating bubbles, ensuring precise filling, and improving packaging consistency. It is a key piece of equipment for ensuring the performance and lifespan of IGBT modules (especially in high-power, high-reliability applications).

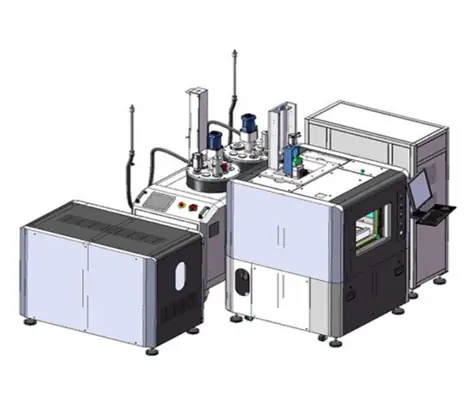

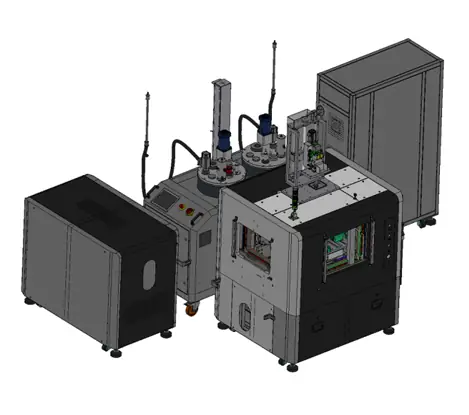

Automatic feeding by vacuum + Glue processing in tanks

+piston pump for metering+Vacuum Environment Potting

RTV effectively suppresses the movement of plug-in components.

●Unique industrial design, elegant appearance, compact structure;

●Fast pumping speed, low noise, quantitative dispensing, high dispensing accuracy, high proportional accuracy;

●Vacuum feeding, vacuum degassing, pressure monitoring, real-time liquid level display;

● Three online independent vacuum boxes, full negative pressure environment glue injection

● Three vacuum pumps imported from Germany evacuate the three vacuum boxes respectively, with fast pumping speed and low noise

● Quantitative glue dispensing, high glue dispensing accuracy, high proportional accuracy

● Vacuum feeding, vacuum degassing, pressure monitoring, real-time liquid level display, etc.

● Unique industrial design, elegant appearance, compact structure

● Unique industrial design, elegant appearance, compact structure

● Fast pumping speed, low noise, quantitative dispensing, high dispensing accuracy, high proportional accuracy

● Vacuum feeding, vacuum degassing, pressure monitoring, real-time liquid level display

Do not hesitate to contact us for further information, thanks in advance for your support!