Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

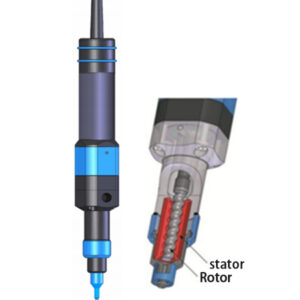

Second Screw valve assembly dispensing Valve

●Screw potting valve is a way of engaging the outer screw with the inner screw, each pitch

has a displacement size as a measure.

●Accurate dosage and stable dispensing

●Suitable for micro-dosing

●The valve is self-sealing and suitable for a wide

range of medium and high viscosity fluids

Second Screw valve assembly dispensing Valve

●Screw potting valve is a way of engaging the outer screw with the inner screw, each pitch

has a displacement size as a measure.

●Accurate dosage and stable dispensing

●Suitable for micro-dosing

●The valve is self-sealing and suitable for a wide

range of medium and high viscosity fluids

PUR hot melt adhesive machine features:

● Floor-standing design, dual motors, dual pumps, dual

divergent seat independent of the first with

● Horizontal pump body installation using buffer connectors, better calibration of the connection level.

● New guided return valve, more accurate and stable adjustment.

● Frame-type body structure, simple and fast installation and maintenance.

● Double-layer penetrating Teflon coating inside the melting cylinder, progressive large fin heating part, enhance the efficiency of melting glue to save energy and effectively

reduce the phenomenon of carbonization.

Functional features:

● Higher pressure ratios, 36:1 available

● Conveys a wide range of fluids from low to high viscosity, suitable for 5 gallon packages of all types of glue.

● Higher outlet pressure, the maximum pressure can reach 400Bar, more suitable for the application of ultra-high viscosity glue.

● Equipped with a special regulator to reduce reversing pressure pulsation, better dispensing effect.

● Suitable for all kinds of medium and high viscosity liquid

transportation, such as glass glue, silicone glue, RTV glue, thermally

conductive gel, thermally conductive silicone grease and so on.

Features:

1. Used for fluid metering and shut-off action in the flow channel, with a firing pin type shut-off glue.

2. Suitable for low and medium viscosity fluids.

3. High precision glue volume control.

4. Mechanical volume control.

5. Rich optional configuration.

Application:

● Bottom Filling ● Surround Dam Filling ● Bezel Bonding & Sealing

● Chip Binding ● Pin Encapsulation ● Precision Coating

Floor-standing platform performance:

● CCD visual programming precise positioning, visual correction, improve programming efficiency and dispensing accuracy;

● Chinese and English operating system, clear software interface layout, simple operation, easy to learn and understand;

● Support visual inspection, integrated control of dispensing and visual inspection, one machine for multiple uses, effectively control dispensing yield;

● Can be equipped with a line laser scanner for 3D path guidance to achieve flexible dispensing;

● The software can support a variety of dispensing systems and functional module applications, such as automatic needle alignment, automatic height measurement, dispensing weighing compensation, five-axis linkage and other functions,

effectively overcome the difficulties of various dispensing processes and help improve dispensing quality;

This machine is suitable for UV-packaging, hot melt adhesive dispensing robot bonding, epoxy bottom filling (underfill) and other precision dispensing processes.