Copyright © 2025 Shenzhen Second Intelligent Equipment Co., Ltd All rights reserved.

For dispensing applications in SMT (Surface Mount Technology) and PCB assembly, common solutions mainly revolve around three core requirements: precision control, automation integration, and process adaptation. The following are the mainstream dispensing technologies and solutions in the industry:

I. Dispensing Technology Types:

1. Time/Pressure Dispensing (Traditional Method)

2. Screw Pump Dispensing

3. Pneumatic injection glue dispensing valve

4. Piezoelectric Dispensing

II. Key Application Scenarios and Solutions:

1. SMT Red Glue/Adhesive Dispensing

2. Underfill

3. Potting/Encapsulation Adhesive

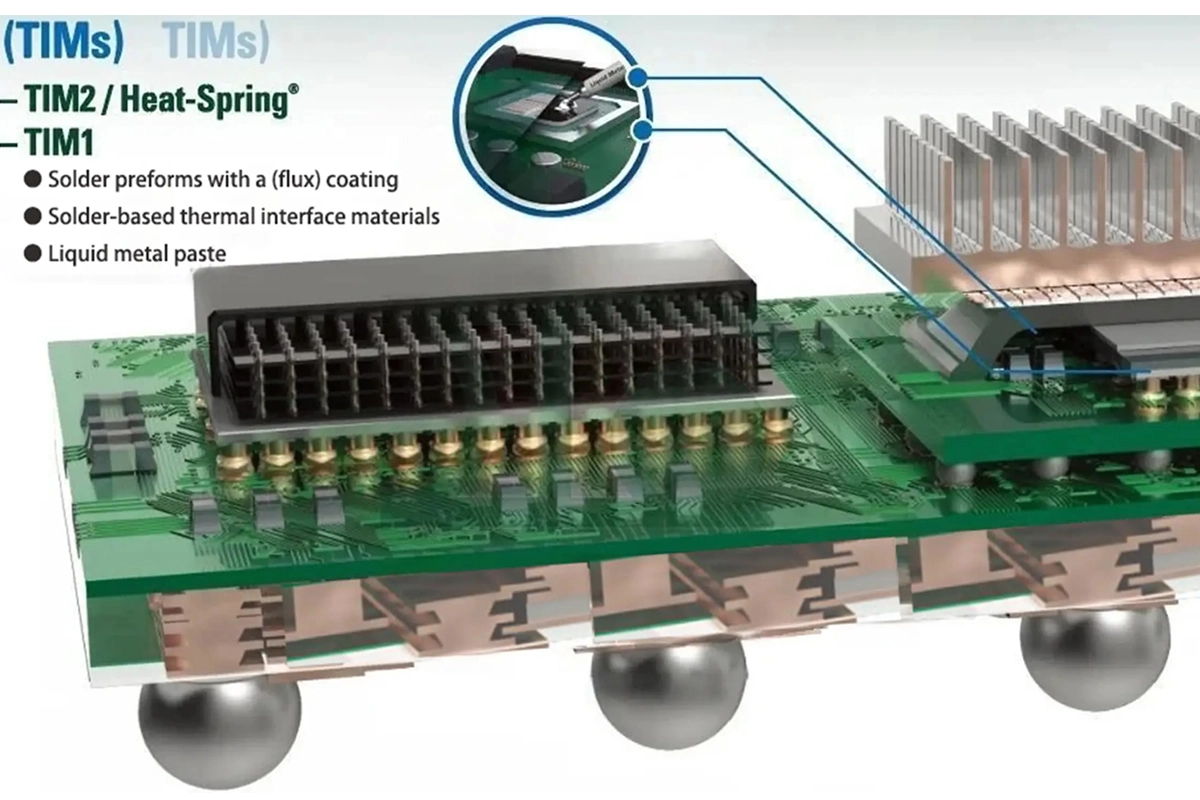

4. Thermally Conductive/Conductive Adhesive Dispensing

Visual positioning + laser height measurement + syringe dispensing

RTV effectively suppresses the movement of plug-in components.

●CCD visual programming precise positioning, visual correction, improve programming efficiency and dispensing accuracy;

●Chinese and English operating system, the software interface layout is clear, the operation is simple, easy to learn and understand;

●Support visual inspection, integrated control of dispensing and visual inspection, multi-purpose machine, effective control of dispensing yield;

●It can be equipped with a lin e laser scanner for 3D path guidance and flexible dispensing;

●The software can support a variety of dispensing systems and functional module applications, such as automatic needle alignment, automatic height measurement, dispensing weighing compensation, five-axis linkage and other functions, which can effectively overcome the difficulties of various dispensing processes and help improve quality

● The platfomm and X/Y module base are made of mineral casting, and the key surfaces are processed by grinding to ensure higher precision and

stability.

● Gantry typestructure, withstand large loads, stable structure, and

● Powerful vision positioning system, can meet the Mark point positioning, grasping edge positioning, 3D scanning positioning.

● Strong expandability, can extend the AOl inspection 3D inspection, UV

exposure curing and other functions.

● Powerful platfom compatibility, contact and non-contactdispensing. single-head and multi-head synchronized dispensing, automatic

compensation and adjustment of the distance between the two heads. five-axis dispensing function basedon the needle A’R displacement, etc.

• High stability:

Marble integrated platform, stable equipment structure. First-line brand components are selected, with fewer vulnerable parts and fewer faults.

• Flexibility:

The automatic width adjustment of the track can adapt to dispensing products of different sizes.

The needle head can be tilted and rotated, automatically aligned, automatically measured in height, automatically weighed, automatically wiped, and dual valve synchronous/asynchronous, etc., which can be flexibly equipped with various functional modules to meet various dispensing processes and achieve high-precision dispensing.

Do not hesitate to contact us for further information, thanks in advance for your support!