- HOME

- MACHINES

-

APPLICATIONS

- Automotive Electronics Dispensing Solutions

- Overall solution for lithium battery equipment

- Consumer electronics industry equipment solutions

- AR equipment overall solutions

- IGBT Industry Equipment Solutions

- Power supply industry equipment solutions

- Vacuum injection industry solutions

- Hydrogen power intelligent equipment solutions

- LED Light Dispensing Solutions

- Home Appliance Industry Solutions

- SMT & PCB Assembly Dispensing Solutions

- Semiconductor Components Dispensing

- ACCESSORIES

- NEWS

- ABOUT US

- CONTACT US

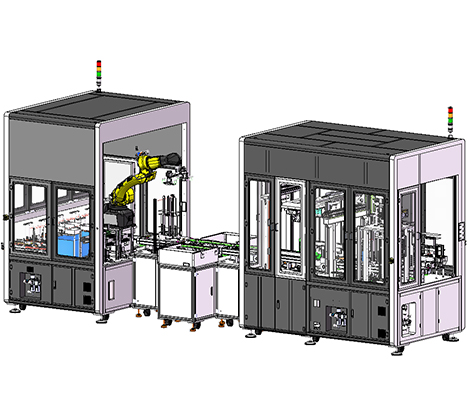

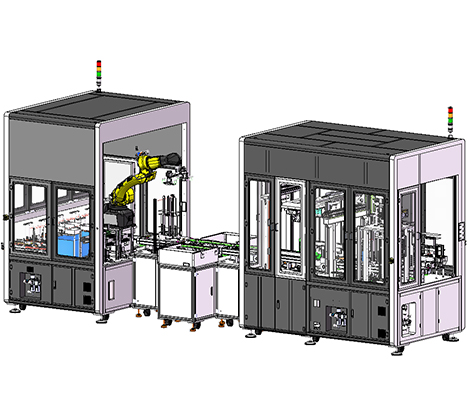

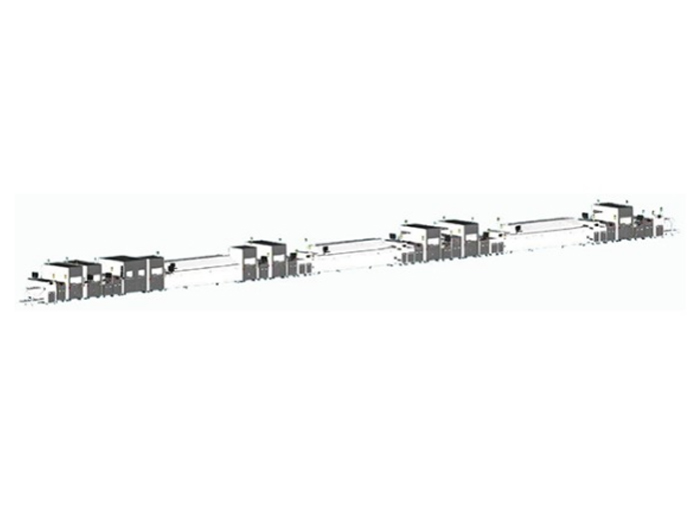

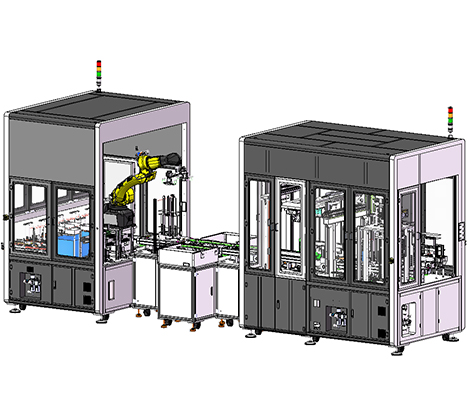

Air cooled reactor loading line

SEC-H500-3TLR

Feature :

Multi-station feeding mechanism can realize non-stop feeding function

After product positioning, the robot automatically and efficiently stacks

Adopts multi-speed servo stacking and real-time force feedback

Online air tightness detection: pressure difference method and flow method

Historical data storage, parameter traceability

Main process

The production line uses robots to automatically grab MEA/bipolar plates, current collectors, temperature measuring plates, end plates and other battery stack components, assemble them into battery stacks after secondary positioning, and then high-precision servo presses perform stacking process. The equipment automatically tests the air tightness of the battery stack, and finally manually locks the battery stack studs before the product is offline.

Advantage :

- Accept production capacity customization and different process combinations. The line can be operated as a whole line or as a single machine offline.

- Reserve AGV docking interface

- The control system is an independent, modular, and standardized program

Application process :

Related content :

*Pre-sales services:

Providing solution consulting based on customers’ needs

Free sample test

Factory audit

Customized solutions according to customers’ needs

*Services during sale:

Production visualization

Machine quality controlling

Finished Machine test report

Logistics support upon customers’ requirement

*After-sales service:

Instruction manuals, step-by-step guides for installation and usage, and free remote video technical support

On-site technical service in 24 hours

Generally, we pack our goods with proper wooden box. However, if client has special requirment, we can customize.

Depends on terms and conditions, negotiable.

EXW, FOB,CIF…

Yes, we can produce according to the tested result. We can also product base on your design.

Yes, we will test 100% before delivery.

We keep good quality and competitive price to ensure our customers benefit. We respect every customer as our friend and we sincerely do business and make friends with them

Dispensing machine is an automatic machine and equipment that specializes in controlling fluid and dripping, coating, and potting the liquid on the surface of the product or inside the product. The glue dispenser is mainly used for glue and paint in the product process.

Glue dispensers are generally suitable for small products or electronic components, which are more precise; the products of potting dispensers are generally larger.

As long as it is a fluid with a viscosity within a certain range, it can be operated. The glue generally used in the dispenser includes red glue, hot melt glue, silica gel, grease and so on.

Recommended equipment 1

- Name: Production Line Glue Potting Machine

- Model: SEC-H500-3TLR

- Video: Click to view

Equipment Features

Accurate ratio, integrated glue mixing and filling,

to achieve truly fully automated mixing, avoid manual mismatching,

resulting in waste and scrap. Accurate positioning,

fast speed, simple and convenient adjustment, strong versatility,

conventional LED, electronic appliances,

handicrafts can be used. Simple programming, simple operation,

can be used with assembly lines,

anyone can operate the counting function, non-standard mode,

bottom glue mode, liquid level alarm

Recommended equipment 2

- Name: Air-cooled reactor automatic production line

- Model: SEC-H300-QAC07

- Video: Click to view

Equipment Features

①Accept production capacity customization and different process combinations. The line can be operated as a whole line or as a single machine offline.

②Reserve AGV docking interface

③The control system is an independent, modular, and standardized program