Applications of Dispensing Adhesive within a curved screen Middle Frame

Adhesive dispensing for curved screen Middle frames is a crucial and typical application scenario in precision manufacturing. It’s primarily used in electronic devices with curved screens, such as smartphones, smartwatches, tablets, and some high-end televisions.

Below, I will explain this industry application in detail from four aspects: why adhesive dispensing is necessary, its specific applications, the technologies and materials used, and industry trends and challenges.

1.Why Adhesive Dispensing? (Purpose and Importance)

The combination of a curved screen and its frame cannot be as simple as fixing it with clips or screws as with traditional flat structures. Adhesive dispensing technology has become the optimal solution, and its main purposes include:

● Structural Bonding: This is the most basic function. High-strength adhesive is used to firmly bond the screen to the metal or plastic frame, ensuring the integrity and durability of the device’s structure.

● Dust and Water Resistance: By forming a continuous and uniform sealant line at the joint between the screen and the frame, dust and moisture are effectively prevented from entering the device. This is a key process for achieving the device’s IP67/IP68 protection rating.

● Cushioning and Shock Absorption: The adhesive layer itself has a certain degree of elasticity and energy absorption capacity, which can act as a buffer when the device is dropped or subjected to impact, protecting the brittle curved screen from shattering.

● Stress Dispersion: Curved screens inherently possess internal stress, and the device is also subjected to external stress during use. The adhesive layer helps to evenly distribute these stresses, preventing damage to the screen due to stress concentration.

● Enhanced Aesthetics: Precise adhesive application ensures a seamless connection between the screen and the frame, enhancing the overall texture and aesthetics of the product.

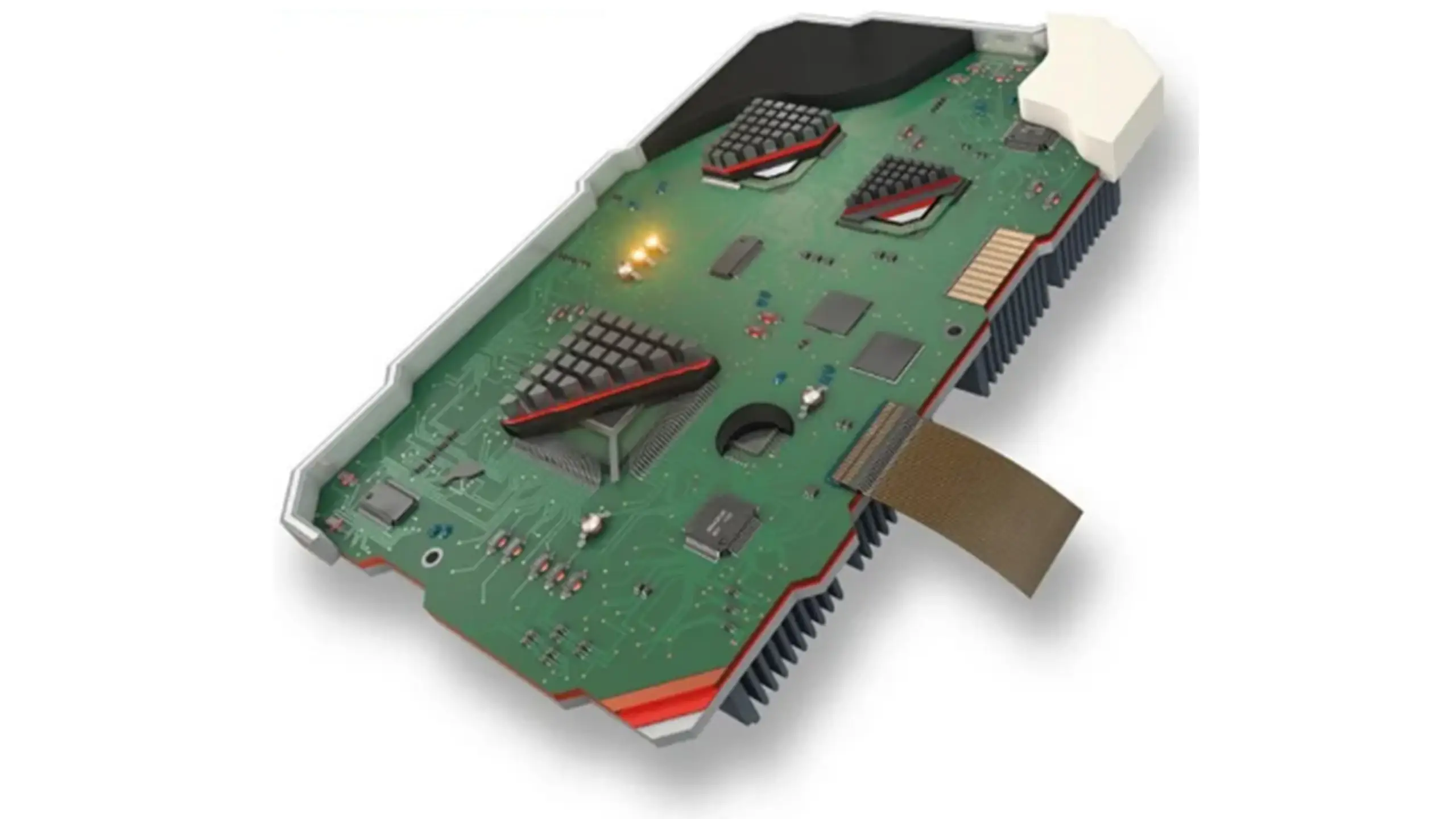

Automatic In-line PCB Glue Dispensing Machine SEC-DH400L

Second Intelligent In-line Automated Glue Dispensing Machine SEC-DH400L adopts an integrated mineral casting design, with ultra-high precision and super stability, powerful expansion capabilities, and can realize ion cleaning, dispensing, detection, UV exposure and other functions;

Adopting a gantry structure, it can bear large loads, stable structure, and a powerful CCD visual positioning system, which can meet the requirements of Mark point positioning, edge positioning, and 3D scanning positioning; strong scalability, and can expand AOI detection 3D detection, UV exposure curing and other functions;

Strong platform compatibility, contact and non-contact dispensing, single-head and multi-head synchronous dispensing, automatic compensation and adjustment of double-head spacing, five-axis dispensing function based on needle A/R displacement, etc.

2.Specific application stages of dispensing

In the entire manufacturing process of curved screen equipment, adhesive dispensing equipment is mainly applied in the following stages:

● Screen Module Bonding to Mid-Frame: This is the most crucial application. Before assembling the curved screen assembly (typically including cover glass, touchscreen, and display) onto the equipment’s mid-frame, adhesive needs to be dispensed into designated grooves in the mid-frame.

● Sealing of Small Components such as Camera Covers and Earpiece Mesh: Besides the main screen, adhesive dispensing technology is also widely used for other small components on the equipment that require sealing.

● Internal Structural Reinforcement: Adhesive dispensing may also be used for auxiliary reinforcement at some critical structural connections.

3.Technologies and Materials Used

Due to the special characteristics of curved screens, the adhesive dispensing technology in this stage places extremely high demands on it.

Core Technologies:

1.High-Precision Visual Positioning System: This is the “eye” for achieving high-quality adhesive dispensing. The system uses a camera to capture the position of the mid-frame and identify the dispensing trajectory, guiding the dispensing valve to perform precise operations and compensating for minor deviations in component placement.

2.Robot Path Planning: For curved screens, the dispensing path is three-dimensional. A six-axis robot or precision motion platform is required to ensure the dispensing head remains perpendicular to the surface and maintains a constant height and speed, ensuring uniform adhesive distribution.

3.Constant Pressure and Quantity Control: Advanced dispensing systems can control adhesive pressure and dispensing volume in real time, ensuring consistent adhesive line width and thickness throughout the three-dimensional path, avoiding defects such as adhesive breaks and build-up.

4.Online Inspection: After dispensing, a separate vision system is typically used to inspect the adhesive line for breaks, width, and position, achieving full inspection and ensuring a high yield rate.

SMT automatic glue dispenser SEC-DH600L

Second Intelligent high precision smt automatic glue dispenser machine apply epoxy resin to the bottom of the PCB board for underfill

Second Intelligent smt automatic glue dispenser automation SEC-DH600L has the following advantages:

● CCD visual programming precise positioning, visual correction, improve programming efficiency and dispensing accuracy;

● Chinese and English operating system, the software interface layout is clear, the operation is simple, easy to learn and understand;

● Support visual inspection, integrated control of dispensing and visual inspection, multi-purpose machine, effective control of dispensing yield;

● It can be equipped with a lin e laser scanner for 3D path guidance and flexible dispensing;

● The software can support a variety of dispensing systems and functional module applications, such as automatic needle alignment, automatic

height measurement, dispensing weighing compensation, five-axis linkage and other functions, which can effectively overcome the difficulties of

various dispensing processes and help improve quality;

Key Materials:

● Adhesive Types:

UV Curing Adhesive: Fast curing speed; initial fixation is achieved within seconds of UV irradiation, facilitating subsequent operations. However, there may be issues with uncured areas in shaded regions.

Thermosetting Adhesive: Cures in an oven, providing uniform and thorough curing with stable performance.

Moisture Curing Adhesive: Cures by absorbing moisture from the air; commonly found in some silicone sealants.

Hybrid curing adhesives (e.g., UV + heat curing): Combining the advantages of both, UV irradiation is used for initial positioning, followed by heat curing to achieve final strength. This is currently the mainstream advanced solution.

● Adhesive performance requirements: It must possess suitable viscosity, good thixotropy (non-flowing), high bond strength, long-term reliability (resistant to aging, high and low temperatures), and reworkability (able to be safely separated during maintenance).

4.Industry Trends and Challenges

● Trends:

Fully automated: The automatic glue dispenser machine dispensing process is integrated with loading/unloading, cleaning, bonding, and curing processes to form a fully automated production line.

Intelligent and data-driven: Utilizing industrial internet technology, dispensing process parameters (pressure, flow rate, trajectory) are monitored in real time. Big data analysis is used to predict equipment maintenance needs and optimize process parameters.

Flexible production: A single dispensing system can adapt to the production of screens of different models and curvatures through program switching, meeting the market demand for “small batches and multiple varieties.

Challenges:

Extremely High Precision Requirements:** Adhesive line width is typically only between 0.2mm and 0.5mm, and trajectory deviation must be controlled at the micrometer level.

Balancing Yield and Efficiency:** It’s crucial to ensure extremely high bonding and sealing yield (>99.9%) while meeting production line cycle time requirements.

Adhesive Management Stability:** Adhesive viscosity, temperature, and air bubbles all affect dispensing quality, requiring a stable adhesive supply system.

Difficult Rework:** Once the adhesive has cured, the screen and mid-frame are tightly bonded, posing a significant challenge to subsequent repairs. Developing adhesives or processes that facilitate rework is essential.

Summary:

Applying adhesive to the mid-frame of curved screens is a technology-intensive core process in modern consumer electronics manufacturing. It’s not merely “applying glue,” but a high-end application integrating precision mechanics, automated control, machine vision, and new materials science. The maturity of this technology directly determines the reliability, waterproofing, and production yield of curved screen equipment, making it a key area of research and competition for major mobile phone manufacturers and automation equipment suppliers.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.