Two groups of CCTV reveal FOTILE’s “Future Factory”, Second helps upgrade the automatic adhesive production line to take the lead

On March 23rd, FOTILE, in collaboration with CCTV News, launched a live-streaming event themed “Spring Brings a Hundred Flavors” during the Spring Equinox, embarking on a dual experience journey of a spring feast of flavors and exploring China’s high-end kitchen appliances. During the factory tour, CCTV host Sa Beining led the audience to explore FOTILE’s “future Factory” from the first-person perspective. Among them, FOTILE’s original automated equipment and production lines for the kitchen appliance industry, such as the automatic adhesive line, have achieved less manpower, automation, intelligence and integration of the production line, showcasing the beauty of modern industry and leaving a deep impression on the audience with their unique charm.

(Source: FOTILE Video Account)

What makes the automatic adhesive intelligent production line of the “Future Factory” of Ningbo FOTILE Kitchenware Co., LTD. (hereinafter referred to as “FOTILE”) so magical? It was created with the assistance of Second Intelligent has opened up new industrial scenarios. From material feeding, visual recognition, gluing to pressing, each process is perfectly connected. In a small space, the robot moves nimbly, demonstrating its hardcore “technology”. Through effective management of each production process, the finished products have zero defects in quality and do not delaminate for twenty years…

The entire adhesive workshop is clean and tidy, and the automatic detection process is visually identifying the product models. The six-axis robot is automatically attaching tape, automatically identifying the remaining amount of tape and automatically changing the tape trays. The three-axis dispenser robot is applying silicone and hot melt adhesive. The mechanical hand is shuttling in the track, with arc light dancing. Press the pressing button, and the glass panel will be pressed rapidly on the assembly line. After 10 seconds, it will be lifted automatically…

Click to watch – Second Intelligent’s first generation of automatic adhesive production line

Empowered by technology, the “Future Factory” leads new intelligent manufacturing

In 2023, the Department of Economy and Information Technology of Zhejiang Province officially announced the list of the second batch of “Future Factories” in Zhejiang Province for 2022. Among them, FOTILE, a leading brand of high-end kitchen appliances, was successfully selected. On the path of transformation towards lean intelligent manufacturing, Fangtai has already taken the lead in the industry.

The construction of “Future Factories” was first proposed by Zhejiang Province, aiming to encourage capable and well-grounded enterprises to take the lead in trials. Through digital reform, it drives the reengineering of production processes and the innovation of production methods, demonstrates and leads the industry to accelerate digital transformation and intelligent upgrading, and promotes high-quality development of the manufacturing industry. This time, FOTILE’s digital transformation capabilities and practices have been officially recognized by the list of “Future Factories” in Zhejiang Province in 2022. It will fully play a leading and exemplary role and become an important showcase window for the high-quality development of the manufacturing industry.

Since 2017, Shenzhen Second Intelligent Equipment Co., LTD. (referred to as “Second Intelligent”) has been honored to cooperate with FOTILE on an automatic adhesive production line, providing it with a complete technical solution for the automatic adhesive production line that integrates manual feeding, visual recognition, adhesive tape application, silicone coating, hot melt adhesive application, and lamination processes. Technology empower the “future factory” Jointly build a new force in intelligent manufacturing.

In November 2017, Fangtai signed an agreement with Second Intelligent for the first (first-generation) automatic adhesive production line.

In May 2018, FOTILE signed an agreement with Second Intelligent for the second (second-generation) automatic adhesive production line.

In September 2018, FOTILE signed the first (first-generation) automatic adhesive production line transformation agreement with Second Intelligent.

In November 2018, FOTILE signed an agreement with Second Intelligent for the third (third-generation) automatic adhesive production line.

In September 2021, FOTILE signed an agreement with Second Intelligent for the fourth (fourth generation) automatic adhesive production line.

In March 2022, FOTILE signed an agreement with Second Intelligent for the fifth (fifth-generation) automatic adhesive production line.

In May 2025, FOTILE signed an agreement with Second Intelligent for an automatic adhesive production line.

……

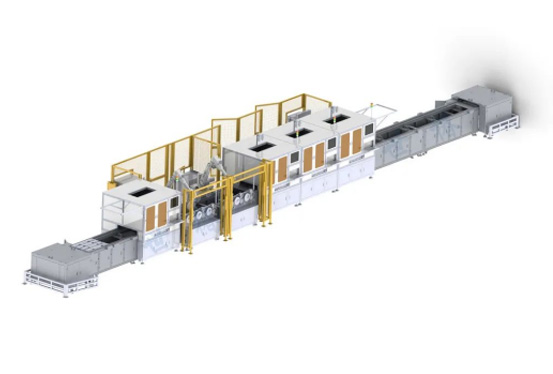

The entire production line adopts an integrated double-speed chain in combination with tooling boards for product transportation. Various functional workstations are arranged on the line for gluing and dispensing operations. The standard automated operation mode allows real-time production scenes of each process to be fully visible. Centralized monitoring of production status ensures the efficient and stable operation of the production line. The debugging efficiency and dispensing accuracy have been significantly improved, with three-dimensional control and intelligent production. In the small space of the robot, we all experience the charm of intelligent manufacturing together… Second Intelligence is gradually turning its “intelligent manufacturing dream” into reality.

This is a brand-new cooperation model between manual and machine operations, which can form a more flexible production mode on flexible production lines and manual operations. It helps enterprises minimize personnel, workstations, and costs as much as possible, increase production capacity, improve product consistency and reliability, and truly achieve cost reduction and efficiency improvement.

Craftsmanship and intelligent manufacturing, concentrating efforts to tackle key challenges

At present, the digital economy and the real economy are deeply integrating, and the process of traditional manufacturing transforming into intelligent manufacturing is accelerating.

To enhance the production and manufacturing level and strongly support the construction of FOTILE’s automated production line, the senior management of Second Intelligent has selected a group of experienced engineers from fields such as mechanics, vision, software, electrical engineering, debugging, assembly, and robot application to form a technical breakthrough team. They have been closely communicating and cooperating with FOTILE. Concentrate on completing the optimization design of the first-generation to fifth-generation automatic adhesive line schemes, production line layout planning, technical breakthroughs and other work, and conduct stability and feasibility tests and verifications on the key processes in the schemes. Based on thorough research and communication, FOTILE organized experts to conduct a comprehensive review of the entire line solution provided by Second Intelligent and ultimately approved it.

Second Intelligent’s complete line solution

In order to meet the requirements of small high-precision glue trays and solve problems such as long time-consuming new product program debugging, poor glue stability, low glue accuracy, high frequency of tool replacement, and high failure rate, the supply chain center closely cooperates with the technical breakthrough team, collaborates efficiently, concentrates the resources of all parties’ suppliers, searches for key components and materials, and ultimately meets the requirements.

The production and operation center has been working hard continuously to complete the production and manufacturing tasks on time with quality and quantity guaranteed. From process control to later inspection and debugging, no detail is overlooked. Through the MES production management system, Second Intelligence centrally monitors the production and operation situation, achieving centralized coordination and dispatching command in aspects such as safety, production, quality, and equipment at the production site. Realize real-time monitoring of key and critical parts and equipment, as well as centralized diagnosis and optimization of on-site production processes and equipment conditions. After the entire production line of equipment is completed, Second Intelligent insists that each machine be carefully debugged and tested by technicians with over five years of working experience to ensure that each machine operates normally for no less than 15 days before leaving the factory, guaranteeing that the project can eventually take root and bear fruit.

Through the collaborative efforts of multiple parties, Second Intelligent has overcome numerous difficulties and successfully completed the production and in-factory commissioning of all automatic adhesive production lines, which have been successfully delivered. After each delivery, Second Intelligent personally dispatches technicians to the customer’s production site for technical supervision, production accompaniment, and operation education and training, ensuring that all production issues are promptly resolved.

Technological innovation leads the high-quality development of the fluid application industry

As China advances from a “manufacturing giant” to a “manufacturing power”, the intelligent transformation and upgrading of the manufacturing industry has become a “compulsory course”. How to make the dispensing production line more efficient, with a higher yield rate and more intelligent has also become the main entry point for the transformation and upgrading of enterprises in the industry. In recent years, Second Intelligent has regarded promoting the construction of intelligent production lines for its clients as a fundamental requirement for adapting to the new stage of economic development, an inevitable choice for deepening integration and fusion, and an important measure for manufacturing transformation and upgrading. It has made overall plans and advanced in depth. By collaborating with FOTILE to build an automatic adhesive intelligent production line, Second Intelligent has achieved a series of new technologies, new results, new performances and new experiences, leading the high-quality development of the fluid application industry.

The first is to achieve information interconnection and interoperability in the visual recognition process. When the product model is identified as incorrect, it can work without stopping the machine. The three-axis mechanical hand is equipped with a vision system, which can quickly connect and communicate with the peripheral supporting equipment of the robot, etc., to convey the instruction that there is a problem with the product model and no adhesive processing is required. Each machine automatically invokes the software program, and each process issues instructions not to execute the adhesive one by one until the product flows out of the end. There is no need for alarms or manual operation to remove the problematic products.

The second is to achieve one-click type change. For general conventional automated production lines, when different models of products are changed for production, each machine needs to be re-debugged and the product model changed manually. In this solution, when changing the product model, it is only necessary to automatically switch the product model through the PLC touch screen of the main control cabinet. There is no need to wait for all the current products to flow out of each workstation, which greatly improves the debugging efficiency and solves the time waste when changing the model of each product.

Thirdly, in the tape application mechanism, the new high-precision adhesive tray has stronger universality and interchangeability, higher tape application accuracy, and realizes automatic switching of the adhesive tray with an error of ±0.5mm. It can achieve rapid material change without stopping the machine, and the operation process does not require human intervention, reducing human input and doubling production efficiency. This adhesive tray is small in size and has a reduced weight. As a result, the load capacity required by the robot system has decreased accordingly, and the cost has also dropped significantly.

Previously, the report of the 20th National Congress of the Communist Party of China clearly stated that it would implement the industrial foundation reconstruction project and the major technological equipment breakthrough project, support the development of specialized, refined, distinctive and innovative enterprises, and promote the high-end, intelligent and green development of the manufacturing industry. Under the strategic background of building a “manufacturing power”, the manufacturing industry has also entered a critical period of adjustment and transformation. With its rich practical experience and leading intelligent manufacturing system, Second Intelligent is helping intelligent manufacturing enterprises innovatively forge a unique path of transformation and upgrading, bringing a brand-new reference sample to the industry.

Amid the industrial development boom of intelligent manufacturing and industrial Internet of Things, the technical processes and application solutions of dispensing machines are becoming increasingly strict. High precision, consistency, automation and even intelligence remain the directions for the continuous innovation and development of modern dispensing machine technology. Second Intelligent, with its forward-looking technical system, complete quality assurance system, and one-stop service support policies, assists intelligent manufacturing enterprises. Cultivate and expand new driving forces for innovative development and technological processes, accelerate the high-quality development of the intelligent equipment industry, and speed up the journey of building a strong country in science and technology. With the courage and passion to brave the wind and waves, write a new chapter and create new glories!