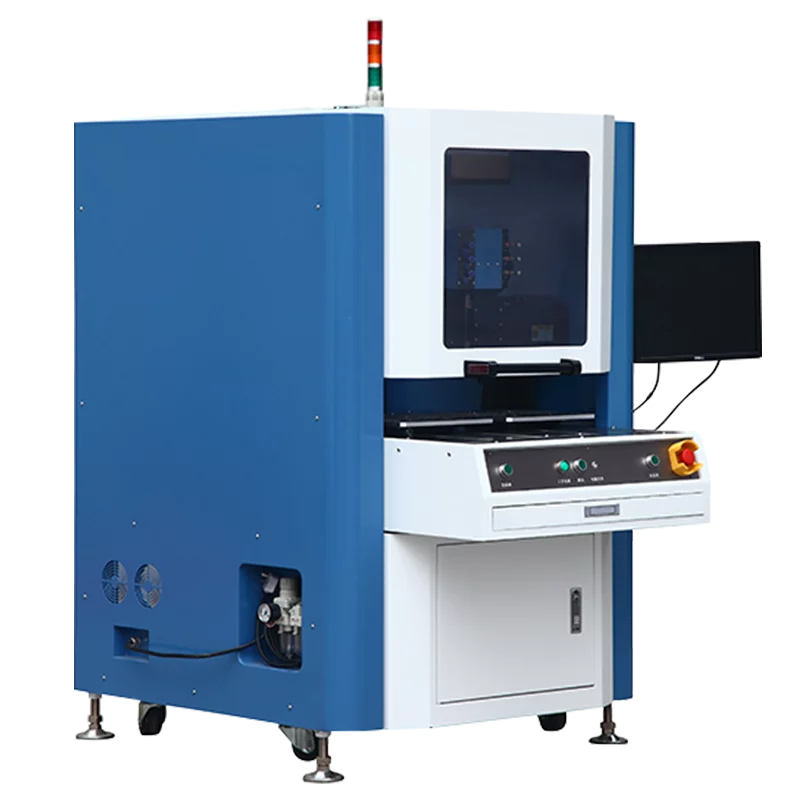

Floor-standing platform performance:

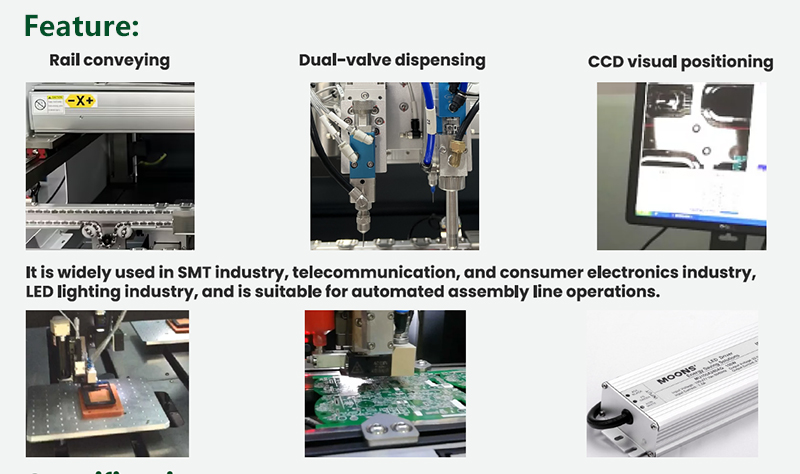

● CCD visual programming precise positioning, visual correction, improve programming efficiency and dispensing accuracy;

● Chinese and English operating system, clear software interface layout, simple operation, easy to learn and understand;

● Support visual inspection, integrated control of dispensing and visual inspection, one machine for multiple uses, effectively control dispensing yield;

● Can be equipped with a line laser scanner for 3D path guidance to achieve flexible dispensing;

● The software can support a variety of dispensing systems and functional module applications, such as automatic needle alignment, automatic height measurement, dispensing weighing compensation, five-axis linkage and other functions,

effectively overcome the difficulties of various dispensing processes and help improve dispensing quality;

This machine is suitable for UV-packaging, hot melt adhesive dispensing robot bonding, epoxy bottom filling (underfill) and other precision dispensing processes.

.jpg)