Automotive dispensing solutions: engine cylinder head and radiator seal dispensing?

Sealing the engine cylinder head and radiator is a critical process in the automotive and industrial engine sectors, and dispensing technology plays a vital role.

Below, I will elaborate on the specific applications, technical requirements, and development trends of dispensing technology for these two components.

1.Applications of Engine Cylinder Head Sealing

The core of cylinder head sealing is the replacement or enhancement of the “head gasket” and the surrounding auxiliary seals. Traditional solid gaskets are being partially replaced by liquid-molded gaskets.

a. Flat Sealing – Liquid-molded Gaskets

This is the most classic and widespread application of dispensing technology.

● Application Areas:

The joint between the cylinder head and cylinder block: This is the most critical seal, requiring it to withstand high-temperature, high-pressure combustion gases, as well as the pressure of engine oil and coolant.

The joint between the valve cover and cylinder head: Seals the engine oil to prevent leakage.

The joint between the oil pan and cylinder block: Seals the engine oil.

Sealing of auxiliary components such as the front and rear covers.

● Adhesive Types:

Room Temperature Vulcanized Silicone Rubber: Offers excellent high and low temperature resistance (-60°C to over 250°C), elasticity, and resistance to engine oil and coolant. Commonly used in low-temperature areas such as valve covers.

Fluorosilicone Rubber: Improves silicone rubber’s fuel and solvent resistance and is suitable for areas that may come into contact with fuel.

Anaerobic Flat Sealant: Cures in the absence of oxygen and metal ions, forming a tough seal with excellent pressure resistance. Ideal for the primary sealing surface between the cylinder block and cylinder head. It fills even minor irregularities, achieving a perfect metal-to-metal seal.

● Dispensing Technology Advantages:

Automation and High Precision: The robotic dispensing system can precisely control the path, width, and height of the glue line, ensuring even distribution of sealant across the flange surface without breakpoints or overflow.

High Material Utilization: This eliminates the waste of solid gaskets, allowing only the required amount to be applied.

Design Flexibility: This allows engine designers to utilize more compact flange structures, eliminating the need to reserve space for solid gaskets and the need for bolt tension.

Improved Sealing Performance: The liquid adhesive completely fills all microscopic irregularities between the two mating surfaces, creating a 100% contact seal.

b. Thread Locking and Sealing

● Application Areas: Various threaded holes on engine cylinder heads and cylinder blocks, such as bolt holes and process holes.

● Technical Key Points: Before the bolts are installed, an anaerobic threadlocking sealant is applied to the threads. The liquid fills the gaps between the threads. Once cured, it prevents the bolts from loosening and effectively seals the threaded assembly, preventing oil, water, and gas leaks.

2. Radiator Sealing Applications

The core of radiator sealing (including the main radiator, intercooler, and oil cooler) lies in the connection between the core and the water chamber, as well as the sealing of pipe joints and other parts.

a. Sealing the Core and Plastic Water Chamber

This is the most critical sealing step in radiator manufacturing.

● Application Area: The interface between the aluminum or copper radiator core and the nylon or plastic upper and lower water chambers.

● Adhesive Type:

One- or two-component epoxy resin adhesive: Offers extremely high bond strength and durability, capable of withstanding the pressure, vibration, and thermal shock of the cooling system. This is currently the most mainstream technology.

Rubber sealant: Also used in designs requiring higher elasticity.

● Key Glue Dispensing Techniques:

High Cleanliness Requirements: Before dispensing, the interface between the core and water chamber must be rigorously cleaned and treated (such as plasma treatment) to ensure proper adhesive penetration and bonding.

Complex Path Tracking: The robot must accurately track the complex two-dimensional or three-dimensional path of the water chamber flange to ensure a continuous and uniform glue line.

Pressing and Curing: After dispensing, the water chamber and core are immediately pressed together and cured in a drying oven or natural methods. The accuracy of dispensing directly determines whether there is any risk of glue overflow or glue shortage after pressing.

b. Sealing of Pipe Fittings and Blanking Caps

● Application Areas: Pipe fittings such as the water inlet, outlet, and bleed valve on radiators, as well as process blanking caps.

● Technical Key Points: Sealant is typically applied to the threads or O-ring groove of the pipe fitting before tightening or press-fitting to provide additional sealing protection.

3. Core Requirements and Development Trends of Dispensing Technology

Whether it’s a cylinder head or a radiator, dispensing technology itself places extremely high demands:

a. Extremely high precision and repeatability: Seal failure can lead to serious engine failure. The dispensing system (robot, pump, valve, controller) must ensure highly consistent dispensing path and dispensing volume every time.

b. Vision Guidance and Inspection:

Guidance: Use a machine vision system to locate the workpiece, compensate for fixture errors, and ensure accurate dispensing paths.

Inspection: After dispensing, use a 2D or 3D vision system to inspect the glue line in real time for defects such as breakpoints, uneven thickness, and positional deviation, achieving 100% in-line quality inspection.

c. Constant pressure and constant volume control: Use a high-precision platen pump or screw pump to ensure constant dispensing volume during the dispensing process, even if the viscosity of the glue fluctuates with temperature.

d. Data Traceability and MES Integration: The dispensing data (time, route, amount, etc.) for each engine or radiator is recorded and uploaded to the Manufacturing Execution System, enabling quality traceability throughout the entire lifecycle.

e. Automation and Flexibility: Dispensing robots integrated into automated production lines can quickly adapt to production changes between different engine or radiator models (flexible manufacturing).

Summary

The application of dispensing technology in engine cylinder head and radiator sealing has evolved from a traditional auxiliary method to a core technology for ensuring product reliability, improving production efficiency, and achieving lightweight design. Utilizing high-precision automated equipment and high-performance chemical adhesives, it achieves superior and more reliable sealing compared to traditional gaskets, perfectly embodying the trend of replacing gaskets with glue in modern high-end manufacturing.

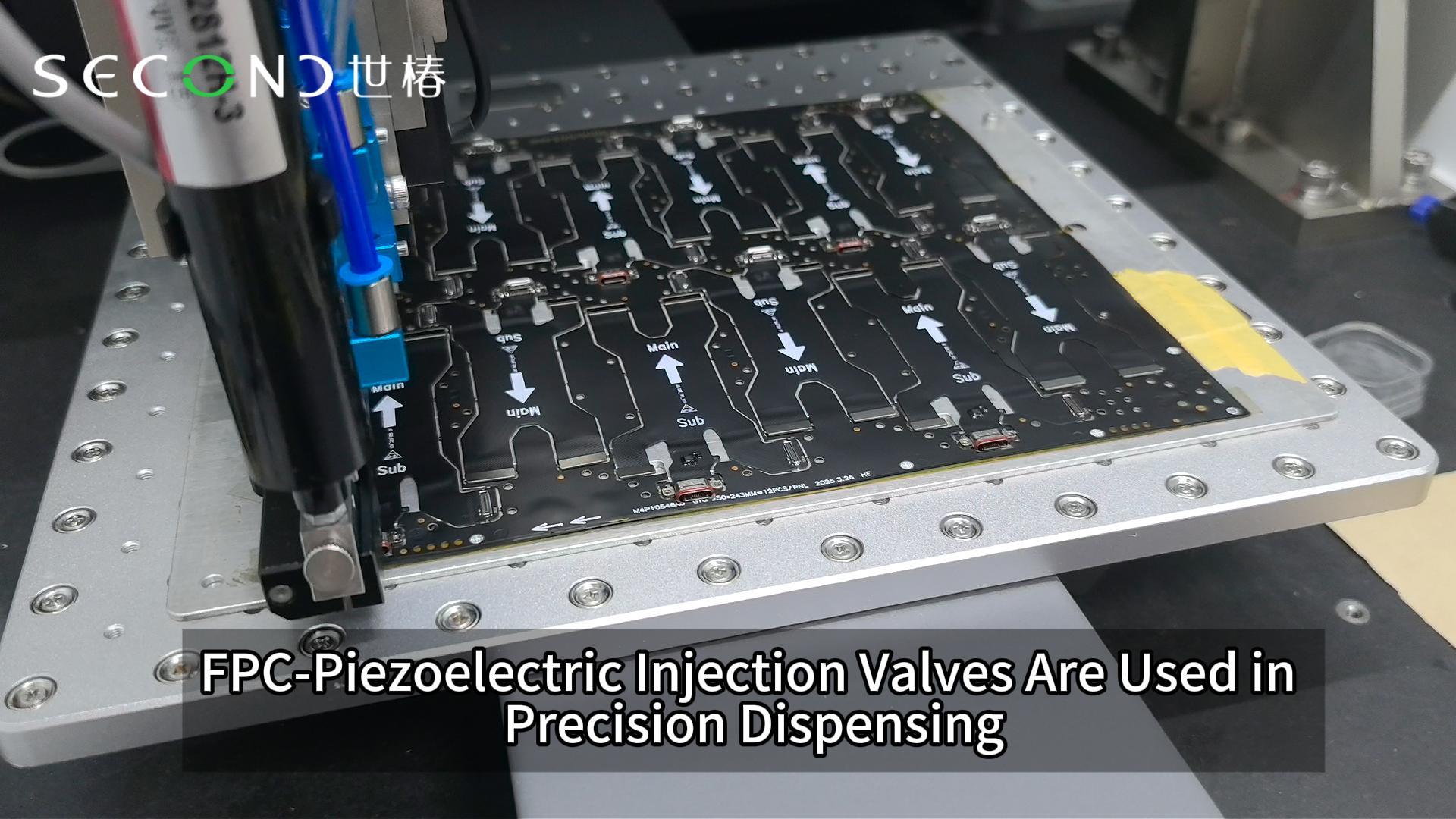

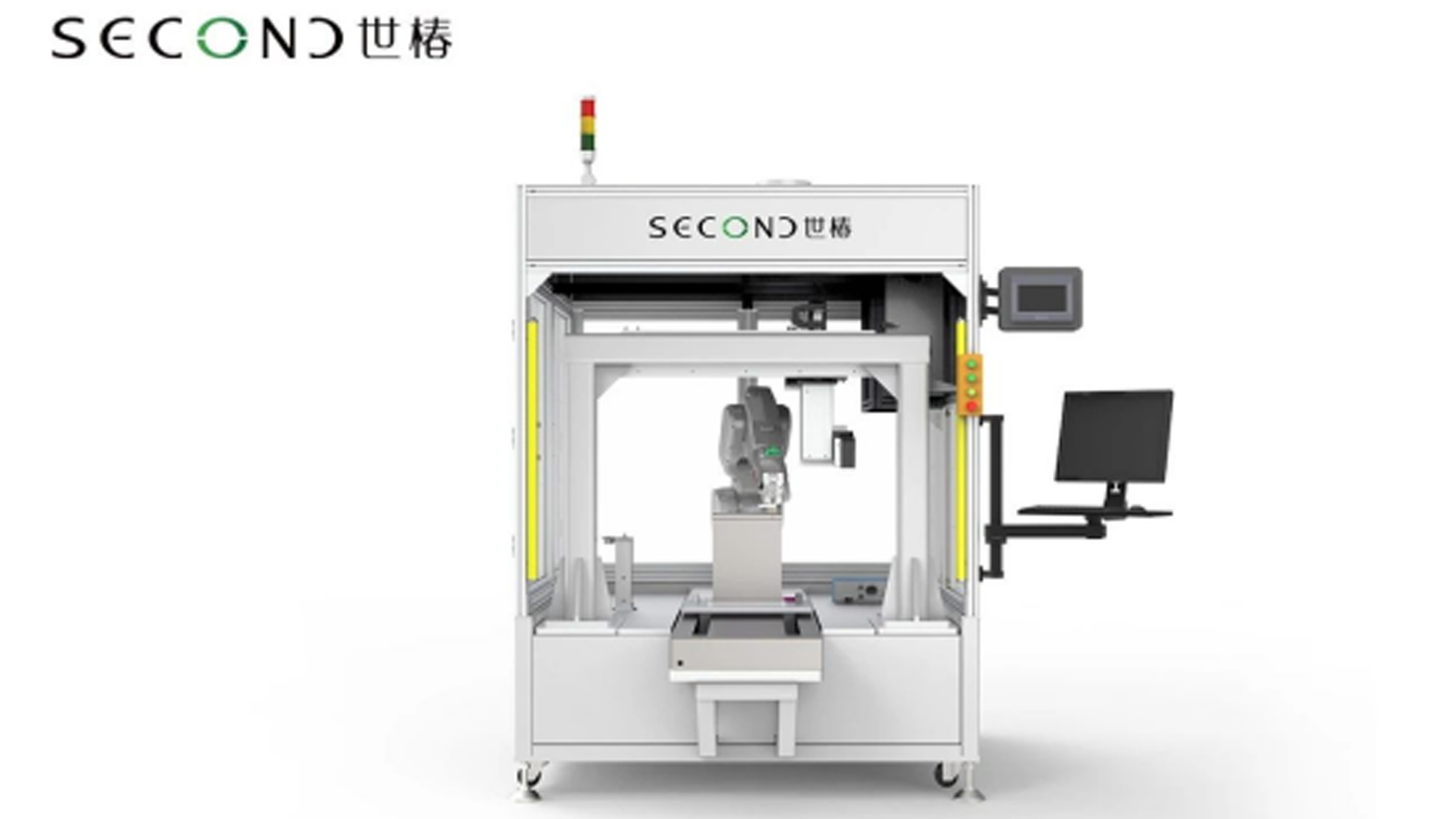

SMT automatic glue dispenser SEC-DH600L

Second Intelligent high precision smt automatic glue dispenser machine apply epoxy resin to the bottom of the PCB board for underfill

Second Intelligent smt automatic glue dispenser machine automation SEC-DH600L has the following advantages:

● CCD visual programming precise positioning, visual correction, improve programming efficiency and dispensing accuracy;

● Chinese and English operating system, the software interface layout is clear, the operation is simple, easy to learn and understand;

● Support visual inspection, integrated control of dispensing and visual inspection, multi-purpose machine, effective control of dispensing yield;

● It can be equipped with a lin e laser scanner for 3D path guidance and flexible dispensing;

● The software can support a variety of dispensing systems and functional module applications, such as automatic needle alignment, automatic

height measurement, dispensing weighing compensation, five-axis linkage and other functions, which can effectively overcome the difficulties of

various dispensing processes and help improve quality;

Second Intelligent’s expertise in the automotive parts industry:

As a high-tech enterprise specializing in the research, development, production, and sales of fluid control equipment, Second Intelligent boasts exceptional technical strength and innovative capabilities in the dispensing machine field. The application of its online fully-automatic dispensing equipment in the automotive parts industry fully demonstrates its expertise.

Second Intelligent’s online fully-automatic glue dispensing equipment utilizes three-axis linkage technology and a sophisticated servo control system to achieve fast and accurate movement of the dispensing head, significantly improving dispensing efficiency. Compared to traditional manual or semi-automatic dispensing equipment, Second Intelligent’s equipment significantly improves dispensing speed and effectively reduces production costs.

In addition, the equipment is equipped with a CCD vision positioning system, which utilizes a high-definition camera and image processing algorithms to precisely identify and locate product positions. This combination of technologies makes the dispensing process more accurate and reliable, effectively eliminating errors caused by human error. Furthermore, the equipment features an automatic calibration function that adjusts the position and angle of the dispensing head in real time to ensure consistent and stable dispensing results.

[contact-form-7 id=”5″ title=”Contact form 1″]