Dispensing Machine Selection Guide: Precise Matching of Products and Adhesives

In intelligent manufacturing scenarios such as electronics manufacturing, automobile assembly, and medical equipment, the adaptability of dispensing machines directly affects product yield, production efficiency, and overall cost. The core selection logic is to ensure a precise match between equipment performance and adhesive characteristics and product requirements, avoiding problems such as uneven adhesive application and machine downtime due to blockages. This article provides a concise and easy-to-understand professional selection solution based on industry practical experience.

1.Basic Understanding of Dispensing Machines

(I) Definition and Advantages

Desktop dispensing machines are devices specifically designed for dispensing fluids onto the surface or interior of products. They offer advantages such as small size, easy operation, high precision, high automation, convenient maintenance, and affordable price, making them suitable for dispensing lightweight and small products.

(II) Working Principle

The adhesive or fluid is propelled from a container using pressure, compressed into tiny droplets by a needle or nozzle, and then quickly detached from the needle or nozzle, precisely coating the target surface. The control system precisely controls the position, size, and speed of the droplets. Combined with accessories such as a worktable, rotary axis, and robotic arm, it enables automated and intelligent operation, improving production efficiency and product quality.

(III) Core Components

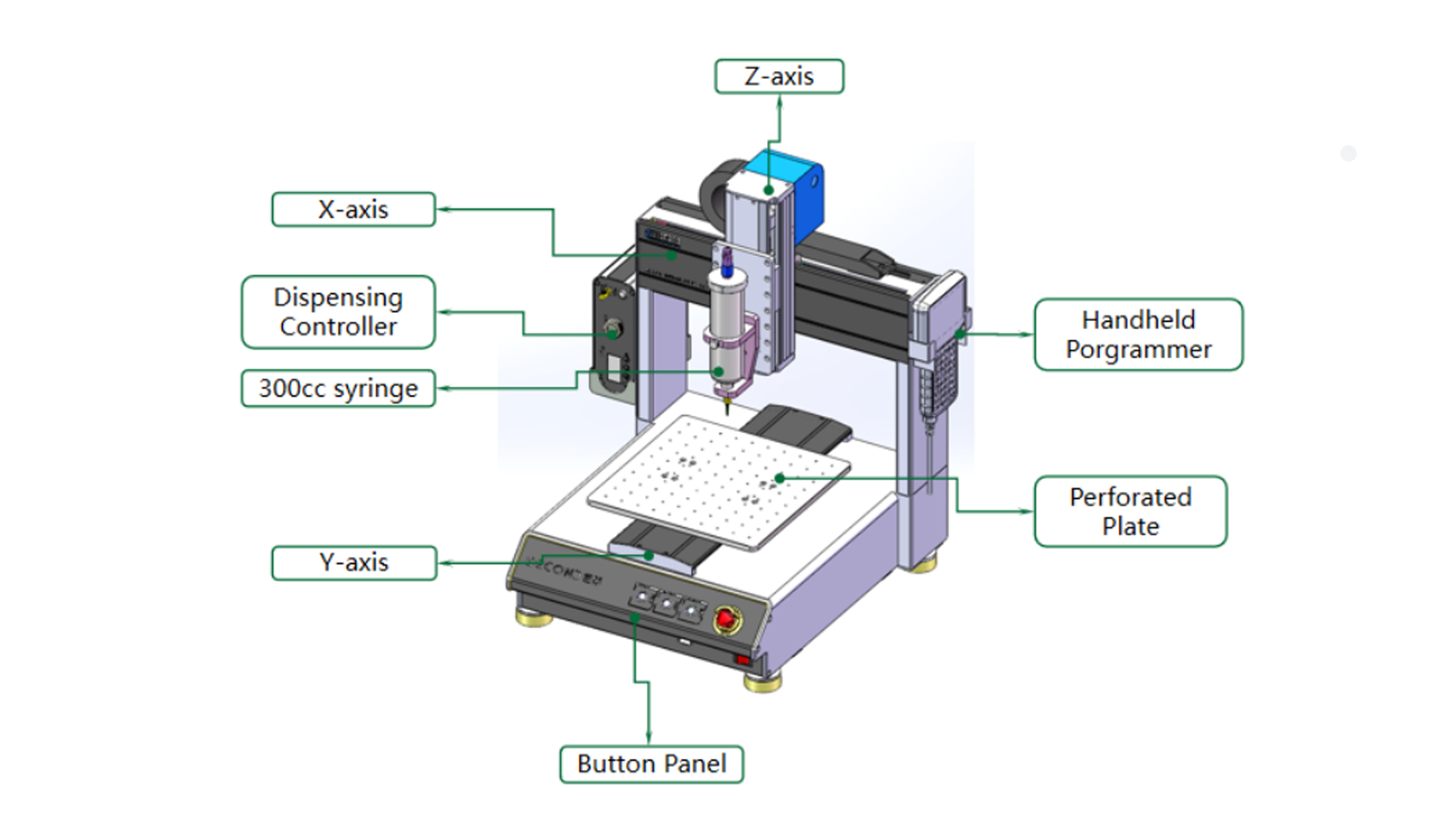

A typical dispensing machine mainly consists of four modules:

1) Platform: Includes the X-axis (lateral movement), Y-axis (vertical movement), Z-axis (vertical movement), control system, and electrical components;

2) Glue Supply Module: Includes syringe/glue bucket series, pressure roller series, and pressure pump series;

3) Glue Control Module: Composed of a controller and valves;

● Auxiliary Function Modules: Divided into platform series (weighing module, needle cleaning module), Y-axis series (rotary axis module, automatic needle alignment module), and Z-axis series (rotary axis module, vision camera module, laser height measurement module, 3D inspection module).

Figure 1. Example of a standard desktop dispensing machine

Ⅱ.Core Selection Criteria

(I) Adhesive Characteristics: The Core Prerequisite for Selection

The physicochemical properties of the adhesive directly determine the core configuration of the dispensing machine. Different types of adhesives require dedicated equipment designs.

1.Key Adhesive Parameters (TDS):

Low-viscosity adhesives can use needle-type or diaphragm-type valves; medium-to-high viscosity adhesives require screw valves or plunger valves; adhesives containing particles require models with large flow channels and wear-resistant parts.

Corrosive adhesives require confirmation that contact parts are made of corrosion-resistant materials such as stainless steel or PTFE.

Thermosetting adhesives require equipment that supports temperature adaptation; for UV-curing adhesives, ensure the valve body material does not block UV rays.

AB adhesives must be equipped with a two-component automatic mixing system.

2.Adhesive Packaging:

Taking hot melt adhesives as an example, common hot melt adhesives are available in rod, block, granular, and powder forms, with varying sizes. For different volumes of hot melt adhesive, Second Intelligent offers 30cc hot melt adhesive module, 300ml hot melt adhesive module, 6-12L hot melt adhesive system, 15-30L hot melt adhesive system, 5-gallon PUR hot melt adhesive system, and 55-gallon PUR hot melt adhesive system.

Figure 2. Different hot melt adhesive module of Second Intelligent

(II) Product Requirements: Determining Equipment Accuracy and Specifications

The accuracy requirements, dimensions, and production scale of the product directly affect the accuracy level, motion system, and equipment type of the dispensing machine. It is necessary to match the requirements accordingly rather than blindly pursuing high-end options.

1.Dispensing Accuracy Requirements

Standard Accuracy (Packaging, Furniture): Manual or semi-automatic models are available, with a focus on dispensing stability and cost-effectiveness.

Medium Accuracy (Consumer Electronics, Automotive Parts): Requires a repeatability accuracy of ±0.02-0.05mm, employing a stepper motor drive and pneumatic dispensing system, with adhesive volume control accuracy around ±1%, suitable for applications such as automotive headlight sealing and electronic component mounting.

High Accuracy (Semiconductor Chips, Medical Equipment): Select models with a repeatability accuracy within ±0.01mm, equipped with a vision positioning system and servo motor + lead screw drive, prioritizing non-contact jetting technology to meet micron-level adhesive dot requirements.

2.Product/Jig Size and Dispensing Range

The size of the product or jig and the dispensing range determine the table size and bearing working range. For example, our popular SEC-E380 dispensing machine has a dispensing range of 380 (X) x 380 (Y) x 110 (Z) mm, suitable for small-sized products. If a jig needs to dispense multiple products simultaneously, a multi-head fine-tuning assembly with 2-4 heads can be selected. For multi-angle and multi-directional dispensing needs, Second Intelligent also offers needle rotation (center rotation, tilt rotation, tilt oscillation rotation) and product rotation (single-station rotation, multi-station rotation, cylindrical rotation, pneumatic tilting, etc.) modules.

3.Production Capacity Requirements

Different production capacity requirements require different configurations. For example, the drive method and control system are selected based on the dispensing speed; whether the equipment is connected to a production line determines whether a conveyor belt is needed; and different chain types, such as belt-type or chain-type, are selected based on product weight.

4.Production Scenarios Adaptability

Desktop Dispensing Machine: Compact size, easy operation, and low cost; suitable for small-batch, multi-variety production, such as small parts bonding and laboratory R&D.

Inline Dispensing Machine: High degree of automation and high production efficiency; supports continuous operation; suitable for mass production, such as automotive electronics and communication equipment production lines. However, it requires a larger footprint and has higher maintenance costs.

Jet Dispensing Machine: High dispensing accuracy and speed; adaptable to various adhesives; suitable for high-precision, high-speed production lines, such as semiconductor packaging and precision electronic component bonding. However, the equipment cost is higher.

5.Auxiliary Function Requirements

The common auxiliary function modules in Second Intelligent and their functions are as follows:

III. Key Considerations for Selecting a Machine and Avoiding Pitfalls

Verify Adhesive Compatibility: Clearly inform the vendor of the adhesive characteristics and confirm equipment material and structure compatibility to avoid clogging or corrosion;

Balance Speed and Accuracy: Avoid blindly pursuing high speeds that may lead to positioning deviations. If necessary, request trial runs to verify consistent adhesive dosage control;

Consider Long-Term Operating Costs: Choose branded models that are easy to disassemble and clean, have readily available spare parts, and offer comprehensive after-sales service to minimize downtime for maintenance.

1.Conclusion: Three-Step Quick Selection Method

Analyze Core Adhesive Information: Clarify key parameters such as adhesive type, viscosity, chemical properties, and packaging specifications;

Define Product and Production Needs: Determine accuracy level, dimensional load, production scale, and special scenario requirements;

Match Equipment Type and Parameters: Select a suitable model based on the above points, or seek customized solutions from manufacturers.