Application cases of dispensing machines in conductive adhesive FIP for new energy vehicles!

The application of dispensing machines in conductive adhesive for FIP (Fiber-in-the-Pack) in new energy vehicles is a very typical and crucial case. FIP in new energy vehicles is mainly used for electromagnetic shielding and grounding, requiring extremely high precision in the dispensing process.

Below is a detailed analysis of an application case:

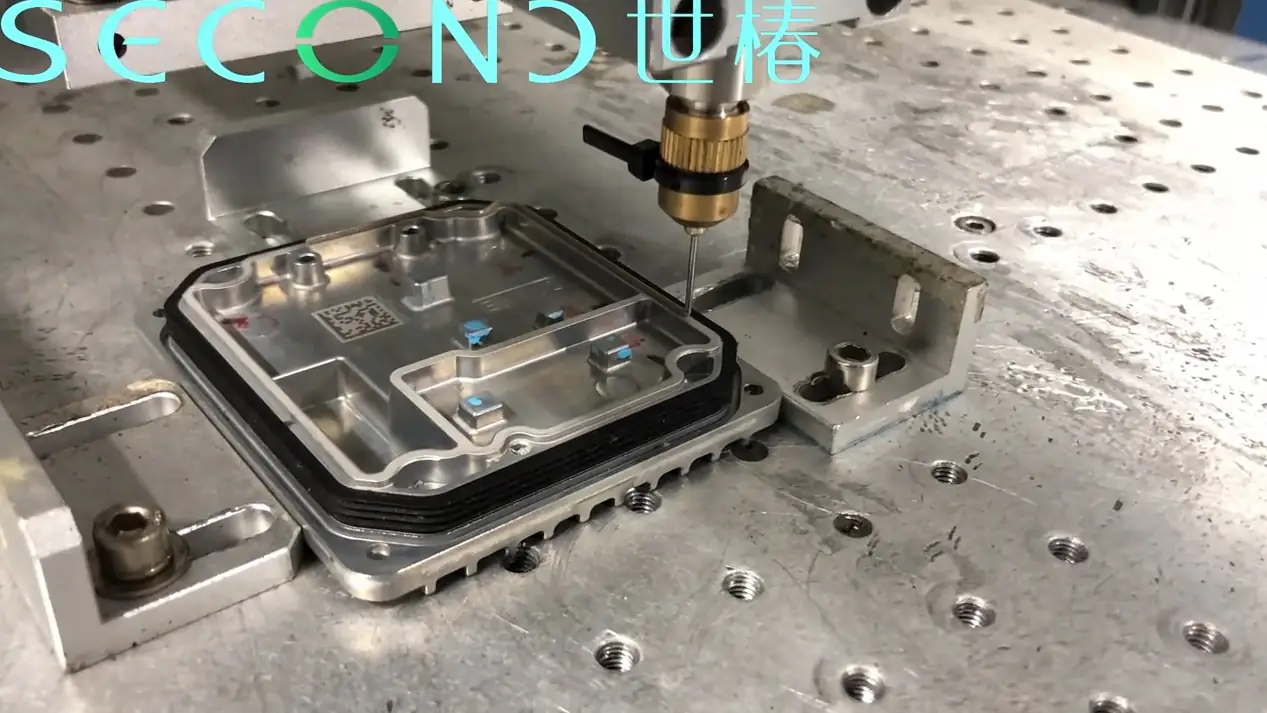

Application Case: Electromagnetic Shielding Sealing for New Energy Vehicle Battery Management System (BMS) Enclosures

1.Background and Requirements

● Component: The Battery Management System (BMS) serves as the “brain” of electric vehicles. Its housing must rigorously protect internal precision electronic components from electromagnetic interference (EMI). Simultaneously, the housing itself requires excellent sealing to prevent ingress of water, dust, and corrosive gases.

● Traditional Solution: Utilization of metal gaskets or conductive foam. However, this approach may suffer from inadequate sealing, uneven installation pressure, and long-term compression set failure.

● FIP Solution: Conductive particles (e.g., silver, silver-clad copper, nickel) are suspended in silicone or fluorosilicone elastomers to form a conductive sealant that can be dispensed and molded. This solution delivers both outstanding environmental sealing (IP67/IP68) and exceptional electromagnetic shielding performance (typically 60-100dB) by creating continuous conductive pathways through the particles.

Automatic In-line PCB Glue Dispensing Machine SEC-DH400L

Second Intelligent In-line Automated Glue Dispensing Machine SEC-DH400L adopts an integrated mineral casting design, with ultra-high precision and super stability, powerful expansion capabilities, and can realize ion cleaning, dispensing, detection, UV exposure and other functions;

Adopting a gantry structure, it can bear large loads, stable structure, and a powerful CCD visual positioning system, which can meet the requirements of Mark point positioning, edge positioning, and 3D scanning positioning; strong scalability, and can expand AOI detection 3D detection, UV exposure curing and other functions;

Strong platform compatibility, contact and non-contact dispensing, single-head and multi-head synchronous dispensing, automatic compensation and adjustment of double-head spacing, five-axis dispensing function based on needle A/R displacement, etc.

2.Challenges in Dispensing Processes

FIP materials are inherently non-Newtonian fluids, exhibiting extreme sensitivity to process parameters:

● Consistency: Shielding effectiveness critically depends on continuous, uniform, and uninterrupted adhesive bead formation. Any air bubbles, breaks, or thickness variations create “gap antennas,” significantly degrading shielding performance.

● Precision and Complex Pathways: BMS housings often feature irregular shapes with corners and radii, demanding strict control over bead width and height (typically 1-2mm wide, 0.5-1.5mm high).

● Material Handling: FIP adhesives contain high metal filler content, prone to settling and abrasion. Continuous, gentle mixing is required without introducing air.

● Adhesion and Curing: Requires strong bonding to metal (aluminum, steel) or plastic housings. Curing conditions (heat or humidity) must align with production line cycle times.

3.Dispensing Machine Solution (System Configuration)

To address these challenges, a comprehensive dispensing system typically includes:

● High-Precision Dispensing Platform:

Robotic/Motion System: Utilizes high-rigidity, high-repeatability linear motors or precision ball screw modules to ensure precise reproduction of complex 3D paths.

Vision System: Performs visual positioning to compensate for minor deviations in workpieces or fixtures; conducts quality inspection to check bead continuity, width, and position inline.

● Specialized FIP Dispensing Valves and Pumps:

Screw Pump/Gear Pump: Preferred solution. Delivers stable, low-pulse output with strong adaptability to high-viscosity, filler-containing FIP adhesives and precise metering (volume accuracy up to ±1%).

Plunger Pumps: Another high-precision option, but requires attention to filler wear.

Pressure Barrels + Timed Pressure Valves: Lower cost but sensitive to viscosity changes with poor consistency, increasingly replaced in demanding applications.

Specialized Valve Bodies: Valves and screws made from wear-resistant materials (e.g., hard alloys) to withstand abrasion from conductive fillers.

● Material Supply and Handling Systems:

Agitation System: Low-speed homogenizing agitators integrated into pressure barrels or feed pumps prevent filler settling without introducing bubbles.

Temperature Control System: Maintains constant temperature for adhesives and workpieces to ensure viscosity stability.

● Software and Control Systems:

Path Programming Software: Supports CAD drawing import, automatically generates dispensing paths, and facilitates adjustment of bead cross-sectional shapes.

Closed-Loop Process Parameter Control: Monitors dispensing pressure, flow rate, and speed in real time, synchronizing with motion axes to ensure consistent adhesive output during corner deceleration and linear acceleration.

Automatic In-line PCB Glue Dispensing Machine SEC-DH400L

Second Intelligent In-line Automated Glue Dispensing Machine SEC-DH400L adopts an integrated mineral casting design, with ultra-high precision and super stability, powerful expansion capabilities, and can realize ion cleaning, dispensing, detection, UV exposure and other functions;

Adopting a gantry structure, it can bear large loads, stable structure, and a powerful CCD visual positioning system, which can meet the requirements of Mark point positioning, edge positioning, and 3D scanning positioning; strong scalability, and can expand AOI detection 3D detection, UV exposure curing and other functions;

Strong platform compatibility, contact and non-contact dispensing, single-head and multi-head synchronous dispensing, automatic compensation and adjustment of double-head spacing, five-axis dispensing function based on needle A/R displacement, etc.

2.Challenges in Dispensing Processes

FIP materials are inherently non-Newtonian fluids, exhibiting extreme sensitivity to process parameters:

● Consistency: Shielding effectiveness critically depends on continuous, uniform, and uninterrupted adhesive bead formation. Any air bubbles, breaks, or thickness variations create “gap antennas,” significantly degrading shielding performance.

● Precision and Complex Pathways: BMS housings often feature irregular shapes with corners and radii, demanding strict control over bead width and height (typically 1-2mm wide, 0.5-1.5mm high).

● Material Handling: FIP adhesives contain high metal filler content, prone to settling and abrasion. Continuous, gentle mixing is required without introducing air.

● Adhesion and Curing: Requires strong bonding to metal (aluminum, steel) or plastic housings. Curing conditions (heat or humidity) must align with production line cycle times.

3.Dispensing Machine Solution (System Configuration)

To address these challenges, a comprehensive dispensing system typically includes:

● High-Precision Dispensing Platform:

Robotic/Motion System: Utilizes high-rigidity, high-repeatability linear motors or precision ball screw modules to ensure precise reproduction of complex 3D paths.

Vision System: Performs visual positioning to compensate for minor deviations in workpieces or fixtures; conducts quality inspection to check bead continuity, width, and position inline.

● Specialized FIP Dispensing Valves and Pumps:

Screw Pump/Gear Pump: Preferred solution. Delivers stable, low-pulse output with strong adaptability to high-viscosity, filler-containing FIP adhesives and precise metering (volume accuracy up to ±1%).

Plunger Pumps: Another high-precision option, but requires attention to filler wear.

Pressure Barrels + Timed Pressure Valves: Lower cost but sensitive to viscosity changes with poor consistency, increasingly replaced in demanding applications.

Specialized Valve Bodies: Valves and screws made from wear-resistant materials (e.g., hard alloys) to withstand abrasion from conductive fillers.

● Material Supply and Handling Systems:

Agitation System: Low-speed homogenizing agitators integrated into pressure barrels or feed pumps prevent filler settling without introducing bubbles.

Temperature Control System: Maintains constant temperature for adhesives and workpieces to ensure viscosity stability.

● Software and Control Systems:

Path Programming Software: Supports CAD drawing import, automatically generates dispensing paths, and facilitates adjustment of bead cross-sectional shapes.

Closed-Loop Process Parameter Control: Monitors dispensing pressure, flow rate, and speed in real time, synchronizing with motion axes to ensure consistent adhesive output during corner deceleration and linear acceleration.

SMT automatic glue dispenser SEC-DH600L

Second Intelligent high precision smt automatic glue dispenser machine apply epoxy resin to the bottom of the PCB board for underfill

Second Intelligent smt automatic glue dispenser automation SEC-DH600L has the following advantages:

● CCD visual programming precise positioning, visual correction, improve programming efficiency and dispensing accuracy;

● Chinese and English operating system, the software interface layout is clear, the operation is simple, easy to learn and understand;

● Support visual inspection, integrated control of dispensing and visual inspection, multi-purpose machine, effective control of dispensing yield;

● It can be equipped with a lin e laser scanner for 3D path guidance and flexible dispensing;

● The software can support a variety of dispensing systems and functional module applications, such as automatic needle alignment, automatic

height measurement, dispensing weighing compensation, five-axis linkage and other functions, which can effectively overcome the difficulties of

various dispensing processes and help improve quality;

4.Dispensing Process Flow

a.Loading and Positioning: Robotic arms or assembly lines feed BMS housings into fixtures, where a vision system performs precise positioning.

b.Surface Pretreatment: Optional plasma cleaning or solvent wiping enhances surface energy to improve adhesion.

c.Dispensing:

The dispensing head moves along the sealing groove on the housing at a constant height (e.g., 0.5mm).

Maintains uniform speed on straight segments and automatically decelerates at corners to ensure bead filling.

A screw pump precisely extrudes adhesive at a preset rotational speed.

d.Lid Closure and Curing:

Lid closure occurs immediately after dispensing (within open time) to achieve preliminary fixation using the adhesive’s tackiness.

The assembly is then placed in a curing oven (thermal curing) or left to rest for a period (moisture curing) to form an elastic, conductive seal.

e.In-line Inspection (Optional but Recommended):

Non-contact height and width measurement of the adhesive bead via laser profilometer.

Alternatively, rapid verification of conductive path continuity through resistance testing.

5.Value and Advantages

Reliable Performance: Achieves seamless shielding and sealing, significantly enhancing BMS operational reliability in complex electromagnetic environments.

Design Flexibility: Unconstrained by preformed gasket shapes, aligning with new energy vehicle trends toward integrated and irregular designs.

Automation and Efficiency: Fully automated dispensing replaces manual gasket application, accelerating production cycles (e.g., 30-60 seconds per unit) with far greater consistency than manual processes.

Weight Reduction & Space Savings: FIP tape cross-sections can be minimized, saving more space and weight than traditional gaskets.

Long-Term Durability: Silicone-based FIP offers excellent resistance to extreme temperatures (-40°C to 150°C+) and aging, ensuring performance throughout the vehicle’s entire lifecycle.

Other FIP Application Points for New Energy Vehicles

Beyond BMS, the dispenser + FIP solution is also widely applied in:

● On-board charger (OBC) and DC-DC converter housings

● Motor controller (MCU) housings

● Vehicle control unit (VCU) housings

● Infotainment system housings

● Sensor housings (e.g., radar/cameras)

● Shielded interfaces for battery packs and modules

Summary

Amidst rising demands for safety, reliability, and intelligence in new energy vehicles, high-precision fully automated dispensing machines have become indispensable core equipment for achieving high-performance FIP conductive adhesive dispensing applications. It resolves the process challenges of FIP materials, translating their theoretical properties into stable, reliable electromagnetic shielding and environmental sealing performance in actual products. This represents a critical technological step in manufacturing new energy vehicle “three-electric” systems and key electronic components. Selecting a dispensing system highly compatible with FIP characteristics—particularly screw pumps combined with precision motion control and vision systems—is key to successfully implementing this process.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.