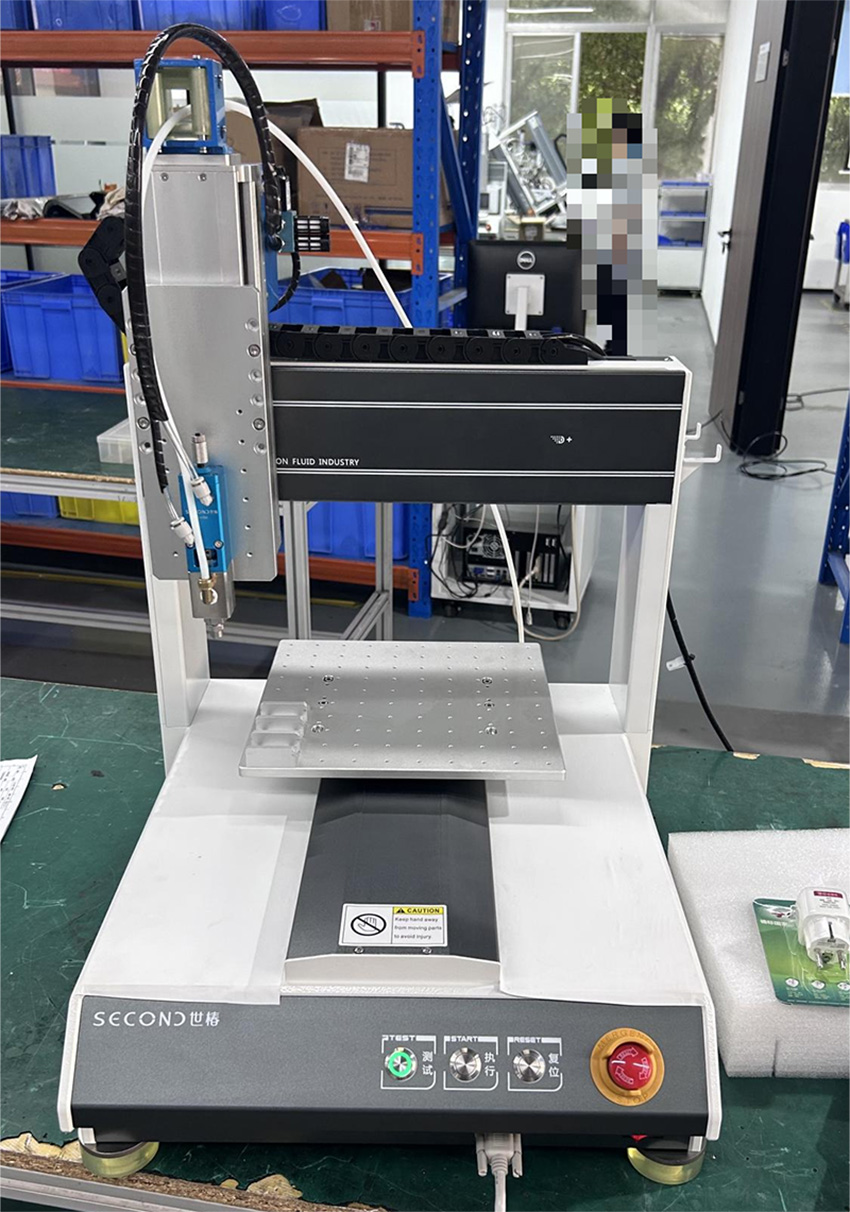

SECOND E-Series Desktop Dispensers: LeChuang Handle & Cost-Effectiveness, Trusted Globally

In the dispensing processes of electronics manufacturing, 3C digital, hardware & plastic, and other industries, operational ease, cost-effectiveness, and adaptability are core considerations for SMEs when selecting equipment. SECOND Intelligent’s E-Series desktop dispensers—including SEC-E380, SEC-E480, SEC-E580Y, and SEC-E480S—have become the preferred choice for budget-constrained customers, perfectly balancing efficiency and cost. This is thanks to the intuitive programming of the LeChuang handle, affordable pricing, and high recognition in European and Indian markets.

LeChuang Handle: Zero-Threshold Programming

All four recommended models support control via the LeChuang handle, paired with an English handheld LCD screen that transforms complex programming into intuitive operations. No professional technical background is required to get started quickly. The LeChuang handle comes with a wealth of practical features, supporting continuous interpolation of points, lines, surfaces, arcs, and irregular curves. It easily achieves 3D non-planar trajectory dispensing, accurately adapting to both simple electronic component fixing and complex curved surface encapsulation. Its excellent teaching functions include array, graphic browsing, 3D ellipse, common graphics library insertion, group editing, and other advanced operations, significantly reducing program debugging time. It can store up to 999 dispensing program files, meeting the program switching needs of multi-variety, small-batch production. In addition, core parameters such as glue size, thickness, dispensing speed, and dispensing time can all be freely set via the handle. It also supports parameterized anti-curing settings, effectively preventing glue from curing and clogging the needle, reducing material waste and equipment maintenance costs for more convenient operation and efficient production.

Four Core Models: Tailored to Diverse Needs

1) Entry-Level Cost-Effective Choice: SEC-E380

● Core Configuration: Single Y-axis workbench; dispensing range of X380/Y380/Z100mm; driven by X/Y stepper motors + timing belts and Z-axis stepper motor + ball screws; positioning accuracy of ±0.025mm.

● Core Advantages: Compact dimensions (L520×W583×H750mm) and a weight of only 40kg, saving workshop space. High-precision stepper motors paired with imported timing belts ensure accuracy while delivering exceptional cost-effectiveness, making it the top entry-level choice for budget-conscious customers.

● Application Scenarios: Small-batch production such as LED dispensing, small plastic part bonding, and PCB electronic component fixing. Widely used in small and medium-sized electronics factories in India, it has earned numerous praises for its “ease of operation and low cost.”

2) Universal Adaptation Model: SEC-E480

● Core Configuration: Single Y-axis workbench; expanded dispensing range of X480/Y480/Z100mm; maximum load of Y7kg/Z5kg; maximum travel speed of X/Y300mm/s and Z200mm/s; storage capacity of 999 files (up to 65,535 points per file).

● Core Advantages: Enhanced stroke compared to the SEC-E380, improving compatibility by 20-25% to fit larger workpieces. It retains cost-effectiveness while supporting I/O port expansion (standard 1 input/4 outputs, expandable to 10 inputs/10 outputs), enabling flexible connection with various auxiliary equipment.

● Application Scenarios: Bonding of mobile phone and tablet casings, keyboard dispensing, LCD glass substrate encapsulation, etc. Balancing versatility and stability, it is a commonly used model in small and medium-sized 3C manufacturing enterprises in Europe.

3) Dual-Platform High-Efficiency Model: SEC-E580Y Series

● Core Configuration: Dual Y-axis workbench (2 independent Y-axes); dispensing range of X500/Y1400/Y2400/Z100mm; load capacity of 7kg per Y-axis (economic version) or 15kg per Y-axis (precision version); supports alternating operations.

● Core Advantages: Dual-platform design enables parallel operations of “loading-dispensing-unloading,” greatly improving production efficiency. With compact dimensions (L690×W630×H680mm for the economic version), it balances large stroke and space utilization. Equipped with rich expansion modules, it can be upgraded to dual Y-axis dual rotation to achieve 6-axis alternating dispensing.

● Application Scenarios: Mass production processes such as PCB board reinforcement, automotive electronic component encapsulation, and bulk bonding of hardware and plastic parts. Aligning with the large-scale production needs of European and Indian markets, it has gained customer recognition for its “high efficiency and productivity.”

4) Precision-Upgraded Model: SEC-E480S

● Core Configuration: Single Y-axis workbench; dispensing range of X480/Y480/Z100mm; driven by high-precision servo motors + ground ball screws; positioning accuracy upgraded to ±0.015mm; maximum load of Y20kg/Z15kg.

● Core Advantages: While maintaining the compact dimensions of the SEC-E480 (L620×W683×H750mm), it achieves dual upgrades in precision and load capacity. With a maximum travel speed of X/Y500mm/s, it operates more stably and positions more accurately. Offering outstanding cost-effectiveness, it meets the needs of customers requiring moderate precision with limited budgets.

● Application Scenarios: Medium-to-high precision processes such as optical lens dispensing, precision electronic component encapsulation, and epoxy resin potting. Complying with the strict precision standards for equipment in European markets, it is widely used in high-end electronics manufacturing.

Budget-Friendly & Globally Trusted: Confident Selection

All four models uphold SECOND Intelligent’s core positioning of “high cost-effectiveness.” Adopting one-piece aluminum alloy casting design, they reduce the number of parts, improve assembly efficiency, and lower manufacturing costs at the source—allowing budget-constrained customers to access stable, reliable dispensing equipment without compromising quality. Whether for startups, small-batch producers, or enterprises seeking large-scale cost reduction, these models deliver reliable performance at an affordable investment. In overseas markets, the four models have earned high recognition: – European markets value precision and stability. The SEC-E480S (±0.015mm positioning accuracy) and SEC-E580Y Series (high-efficiency dual-platform design) perfectly meet the needs of local automotive electronics and precision manufacturing industries. – Indian markets favor cost-effectiveness and ease of operation. The SEC-E380 and SEC-E480 have become the top choices for small and medium-sized electronics factories, thanks to their “low cost and easy maintenance.” Compatible with UV adhesive, epoxy resin, solder paste, and other glue types, they cover mainstream application scenarios such as mobile phone manufacturing and LED encapsulation. From the entry-level SEC-E380 to the precision-upgraded SEC-E480S, and from the universal single-platform SEC-E480 to the high-efficiency dual-platform SEC-E580Y Series, SECOND’s E-Series desktop dispensers meet diverse customer needs with the LeChuang handle’s easy operation, affordable pricing, and versatile adaptability. Their strong reputation in overseas markets is a testament to their quality and performance. If you are looking for a “simple to operate, cost-effective, and reliable” dispensing solution, these four models are excellent choices for budget-constrained customers, helping enterprises reduce costs, improve efficiency, and expand their market reach.